Stratman

Members-

Posts

48 -

Joined

-

Last visited

Personal Information

-

Location

Pembrokeshire

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Stratman's Achievements

Member (3/5)

26

Reputation

-

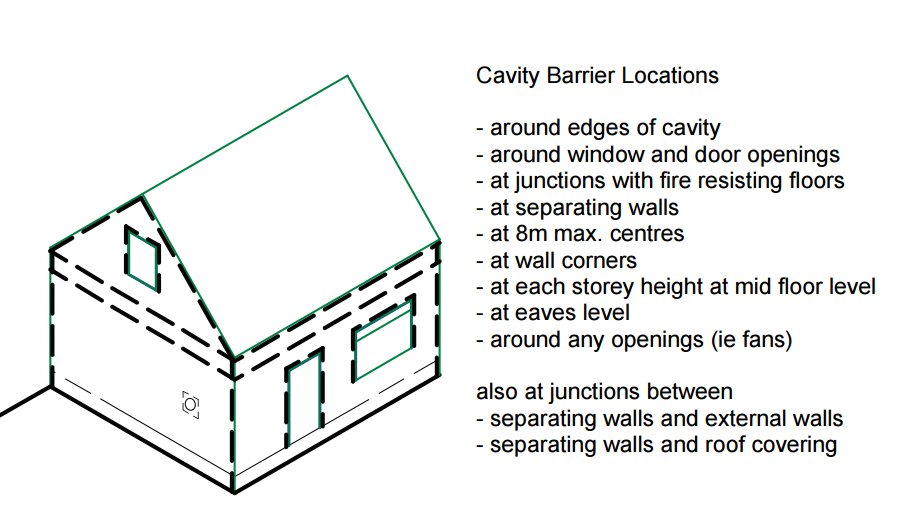

Cavity barriers in external walls FAQ.pdf This document might help with locations for cavity barriers in external walls by LABC Warranty. I also found this diagram helpful:

- 1 reply

-

- 2

-

-

-

Single Dwelling SUDS - full submission example please!

Stratman replied to bodger53's topic in Rainwater, Guttering & SuDS

SUDS Approving Body - fancy name for the council department that deals with them. I think they are part of the civil engineering department as they seem to be the planning application statutory consultee that tells the planning officer to include a SUDS condition in a relevant planning consent. -

Single Dwelling SUDS - full submission example please!

Stratman replied to bodger53's topic in Rainwater, Guttering & SuDS

I'm just going through similar process now. The amount of 'guidance' referred to by the SAB for SUDS is quite overwhelming. Did you get anywhere with this? Apparently I need SAB (also the county council but separate from planning department) approval before any development starts, whereas planners only need the application to have been made before they will partially discharge the condition to the consent. -

Thanks guys. I feel daft for having considered this route, but at least now I have seen the light! Learning is what it's all about on here, right?

-

Yes, I would cover it with a skirting for protection.

-

I've seen several posts on here recommending ducting services through slab. I assumed it was for better insulation and airtightness. Maybe I've got the wrong end of the stick.

-

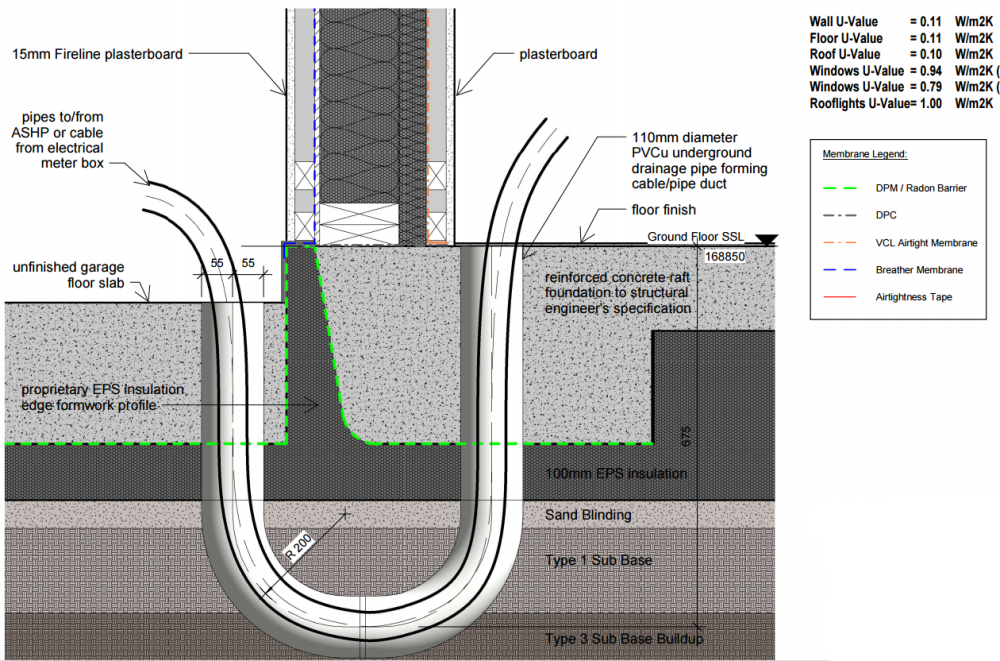

Hi All and Happy New Year! I've been going through Building Control queries to my recent application and came across fire separation between the house and adjoining garage. There will be a connectiond door: FD30 with self closer, that's all fine. It's an MBC timber frame and insulated raft foundation - MBC will install waste pop ups and services ducts through the slab. I would like bring the electrical cable from an outside wall meter cupboard into a consumer unit in the utility. And also run pipes from an ASHP outside via the garage, into the house and to a utility space. I'm proposing this detail below, but would appreciate some feedback on the duct (depth and radius suitability for pipework and cables) and suggestions on how to maintain 30 minute fire separation between the house and garage. Any thoughts?

-

That's quite a limited scope of service. For planning application things like stairs and drainage won't be designed in sufficient detail to submit for building regs. You'll probably need to supplement the design with other details and specs for things like overheating (to part o), stairs and guardrails (to part k), ventilation (part f), accessibility (part m), fire safety (part b), etc. But you've probably looked at those already so apologies if you have that covered. Part o seems to cause a lot of confusion if you want to follow the 'simple' method. It has caused me some headaches.

- 15 replies

-

- passivhaus

- technical

-

(and 1 more)

Tagged with:

-

There's more to technical design than just the timber frame. If you don't appoint (and pay) your consultants to provide this service you can do it yourself if you feel qualified, or go down the design and build route with a general contractor. One way or another you'll pay for it.

- 15 replies

-

- passivhaus

- technical

-

(and 1 more)

Tagged with:

-

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Stratman commented on Benpointer's blog entry in Contemporary build in north Dorset

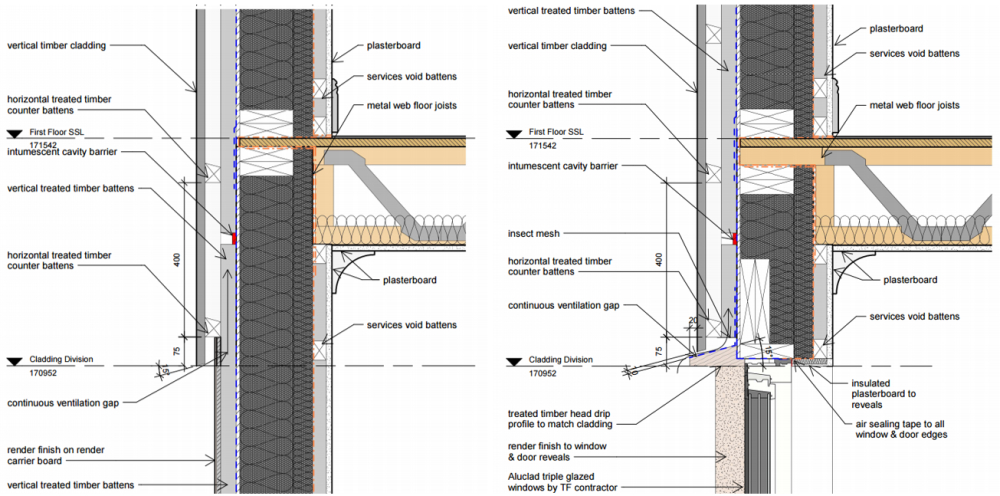

These are the details I'm playing with to get the weep/ventilation gap and finish the window head without rendering. Any thoughts and opinions would be welcome.- 25 comments

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with:

-

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Stratman commented on Benpointer's blog entry in Contemporary build in north Dorset

It's not visible in the photos - did you render the window head reveals? On ours I'm concerned it would be too awkwardto render.- 25 comments

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with:

-

Week 28 - Floor tiling, bathrooms, cladding, MVHR, electrics…

Stratman commented on Benpointer's blog entry in Contemporary build in north Dorset

I do like the look of the Brimstone Ash (from Vastern Timber?). I tried several samples including it as well as Western Red Cedar and British Larch, one set indoors and the other outside to weather. The Brimstone faded to silver grey really quickly. It also proved a good demonstration of why you don't use galvanised fixings which was all I had to hand... black staining within a week! Are you leaving the bottom edge over the windows as in the photo? I am thinking of adding a drip edge piece in timber or aluminium profile. Would you mind sharing the detail?- 25 comments

-

- floor tiling

- cladding

-

(and 2 more)

Tagged with:

-

So, we decided to go with MBC for frame, insulated raft and Rationel windows. They have been so helpful after Scotframe pulled out and I now feel it was meant to be. We completed on our plot purchase yesterday after 3 years of solicitors buggering about so celebrating tonight! Hopefully breaking ground in February.

-

Try these guys: https://www.watersideblinds.co.uk/ We had our whole house done a few years ago and it didnt break the bank.

-

How does the Sprinkler Law work in Wales?

Stratman replied to Ferdinand's topic in General Self Build & DIY Discussion

I believe it's only required for new properties o where they are being converted into dwellings. This guide is useful: https://developers.dwrcymru.com/en/help-advice/domestic-fire-sprinklers