MAB

Members-

Posts

138 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

MAB's Achievements

Regular Member (4/5)

96

Reputation

-

How accurate do we need to follow planning outlines?

MAB replied to dan_cup's topic in Planning Permission

One of my neighbours checked the footprint of his new rear kitchen extension AFTER the foundations had been excavated and filled with concrete and found the rear depth/projection was 0.5 metre more than the approved plans. As expected Building Control were not concerned (ie. only interested in Regs) and local Planning Dept said to go ahead as long as he consulted adjacent neighbours about it and confirmed that they did not object to the extra 0.5m....which luckily they were fine about it...much to builders relief! The kitchen design did have to be slightly re-jigged though to use the extra space! -

Our side passage is 1.0 metre max wide and scaffolding for our 2 storey side extension allowed access below no problem including builders wheel barrows, etc. With your neighbours agreement could you remove any boundary fence temporarily between yours and neighbours side passages, giving you approx 2 x 800mm width in total for the scaffolding and access? Afterwards if it is their fence you can promise them a nice new one as a replacement!

-

Dug my own foundations for a side extension with help from an 'old school' Builder friend who said we could do it without a Mini digger in a few days.....1 metre deep in clay and we just did it with spades and wheelbarrows in 2 sections to make sure the concrete went in before any rain arrived. We also mixed our own concrete in a standard mixer. It was nearly 20 years ago and you need to be fit with good dry weather for digging clay....was easier than I thought but I could not do it now though! 😄 We hit the water table at 1 metre and the following morning there was 6" of water in the bottom of the foundations despite no rain for days but the Building Inspector said pump or bail the worst out and to use a drier concrete mix for the first few barrow loads that went in. He also wanted rebar put in the concrete where the two new foundation sections were to join plus a thick sheet of polystyrene between the existing 1930's house foundations and the new extension foundations.

-

Interesting below that Thames water reckon that Dual Flush toilets waste more water than they save due to leaks... Dual-flush toilets 'wasting more water than they save. https://www.theguardian.com/environment/2020/sep/29/dual-flush-toilets-wasting-more-water-than-they-save "Toilets specially designed to save water are wasting more than they conserve, the UK’s largest water firm has warned. Campaigners have warned for years that dual-flush toilets, introduced as more efficient alternatives that were expected to use less than half the amount of water per flush, are more prone to leaks. The problem is said to be so great that the costs are outweighing the benefits. “Because there’s so many loos that continuously flow all through the day and night, collectively that water loss is now exceeding the amount of water the dual-flush design should be saving,” said Andrew Tucker, water efficiency manager at Thames Water. “The volume of water loss is getting bigger every day as more people refurbish and retrofit older toilets and as more homes are built, so it’s a growing problem.” “A siphon will not leak whereas an outlet valve – if we look at the figures we’ve got – they could leak within a week of installation. It could be two years but they will leak,” said Jason Parker, the managing director of Thomas Dudley Ltd, one of the UK’s largest plumbing manufacturers. He told the BBC: “If we’re serious about wasting water and we want to stop it, the only way to do that is put a siphon back in.”

-

Building Inspectors to become RBIs after the 6th April 2024!!!

MAB replied to Marvin's topic in Building Regulations

My areas local Council Building Control dept was closed in April 2023 and outsourced to a company EBCS Ltd which is apparently 'the first Building Control Mutual in the UK.' https://ebcsltd.co.uk/ -

Replace electric shower with bath and shower

MAB replied to Lifesigns's topic in Bathrooms, Ensuites & Wetrooms

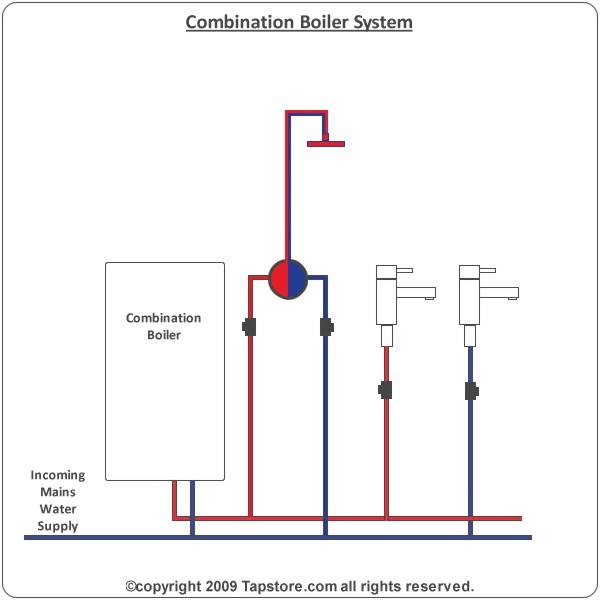

I would have the tank in the loft and the Triton electric shower removed and have a new thermostatic shower valve plumbed in and fed by your combi boiler. Also as stated above your Ferroli Modena 102 Combi is at least 20 years old so it might be worth having it replaced with a newer and more efficient combi to provide your heating and hot water. Combi boilers have improved a lot in the last 20 years! Also make sure the electric supply cable to the existing shower is safely disconnected and isolated by an Electrician if/when the Triton shower unit is removed...water and electricity is not a good combination! -

Replace electric shower with bath and shower

MAB replied to Lifesigns's topic in Bathrooms, Ensuites & Wetrooms

Triton Alicante Electric shower - Specification. Installation - Plumbing System = Cold Mains - see link below:- https://www.tritonshowers.co.uk/alicante-electric-shower#product.group.attributes The tank in your loft looks like a cold water tank to me (sat on a raised platform to improve the head and increase pressure to whatever it feeds) that has been left in the loft when the Combi boiler was installed. Have you ever confirmed the water in it is actually getting hot? Is the tank metal or plastic? Hot water tanks are normally metal (copper/stainless steel) and a cylinder shape. I would think the cold water tank still fed by the mains supply has been wrongly plumbed to feed cold water to the electric shower which heats it.....assuming that white pipe to the shower does not go direct to the mains supply that is/was feeding that tank? Not clear in photo. Simple diagram of how a combi boiler feeds a thermostatic shower valve and hot/cold taps. -

Replace electric shower with bath and shower

MAB replied to Lifesigns's topic in Bathrooms, Ensuites & Wetrooms

As said Electric showers work directly off the incoming cold water mains supply to heat the incoming cold water and do not have/or need a hot water tank in the loft if plumbed correctly. Likewise a Combi boiler also heats the water directly off the cold water mains supply and does not have/or need a hot water tank in the loft. (some combi boilers have a small pre-heated tank within the boiler I believe). Often when a house is converted from an old system boiler to a new combi boiler the old cold water tank in the loft gets left in place even though disused because it won't fit through the loft hatch to remove it. Same could apply to the old hot water tank/cylinder although they are less often located in the loft space. An easy test is does your hot water tank feeding your shower actually get hot at any time! Are you sure you have a combi boiler or could it be the description is being confused with a condensing boiler? -

Anyone done their own building regs plans

MAB replied to Professionally nosey's topic in Building Regulations

I did my own Building Reg drawings, just based them on the Planning Drawings which I also did with more details and a extra sheet of notes. Most of the notes required are pretty standard and can be obtained from the website below or cribed from online BC drawings. Local Authority Planning drawings are usually available for public view online and sometimes include the BC notes, useful if there are similar properties to your own in your road or area to compare with. This is a good website in link below for showing the kind of Building Reg drawing details and notes that are needed for various kinds of extension:- https://www.buildingregs4plans.co.uk/index.php -

You just have to keep the Final Completion certificate from Building Control filed away to produce as proof to any future buyers of the property (and their solicitors) that the work has been inspected and signed off as complying to the current Building Regulations. House sales often get held up due to the lack of a Final Completion Certificate which is not always easy to obtain retrospectively. The council should also have a copy kept on record but usually charge for any new or replacement copies. The Planning Dept are not usually interested in the Building Control side of things and you rarely hear from them after completion unless a nearby neighbour complains that something is not to the original planning drawings.

-

The council are probably worried about migration of your gravel onto the pavement and into road causing a nuisance/hazard to pedestrians and passing vehicles. You could install one of the many types of interlocking plastic grid systems which stabilise the gravel and prevent migration/movement by holding the gravel in individual plastic cells. Angled gravel up to 20mm will move less then rounded gravel. Councils also usually like this gravel/grid system because it allows good drainage compared to hard driveway surfaces which cause rainwater to run off into the road overloading the councils drains in the road gutters. Typical examples in link....there are many different types and suppliers including Wickes, etc. https://www.matsgrids.co.uk/c/gravel-driveways/

-

If it is like the double glazed 'Monaframe' Aluminium Windows I had with external beading, the internal rubber seals (ie. inside room) can be eased out from the between the glass and frame (The rubber seal strips are usually just pushed in as a tight interference fit between glass & frame) This should make the glass unit a loose fit in the frame. The Aluminium beading strips/seals (4-off) on the outside can then be carefully prised out /unclipped from the Aluminium frame extrusions with a thin screwdriver/lever. The glass can then be lifted out the frame from the outside assuming adhesive security tape has not been used to increase security. This then gives access to the hidden screws holding the Aluminium frame into the (usually) hardwood frame. Finally the wood frame can be unscrewed from the brickwork and any sealant or expanding foam holding it in, to remove from the outside hopefully without damaging the internal wall plaster. Of course a window fitter who is not refitting the old frame would usually be a lot more brutal in the removal process to save time, probably involving the use of hammers, chisels and saws.... Note: Most modern uPVC or Aluminium windows have the removable beading on the inside to further improve security... Monarch/Monaframe Aluminium (discontinued 2010) windows:- https://www.aluminiumtradesupply.co.uk/10450/looking-monarch-aluminium-windows/

-

In England or Wales you need a 'Party Wall Agreement' between you and your neighbour but not sure if anything similar in Scotland? Party walls and building work:- https://www.gov.uk/party-walls-building-works