BotusBuild

Members-

Posts

1207 -

Joined

-

Last visited

-

Days Won

10

BotusBuild last won the day on February 1

BotusBuild had the most liked content!

Personal Information

-

About Me

40 years in IT, then made redundant, which has helped enormously in building. Helped with building renovations and extensions, but it was always a dream to build our own energy efficient house. Well, here we are having started (properly) in late 2020, and very proud of what we have achieved (so far!)

-

Location

South East Cornwall

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

BotusBuild's Achievements

Advanced Member (5/5)

566

Reputation

-

ASHP outdoor unit heating pump Q

BotusBuild replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

John, the current setup works. We are comfortable the way the loops are and by adjusting flows to each. I am only interested in whether I can remove or bypass the buffer tank and rely on the heating pump in the outdoor unit to continue to make the water flow through the UFH.- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

ASHP outdoor unit heating pump Q

BotusBuild replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

@SimonD, is there anything else you are seeking information about? A bit more below. FYI the heat pump is about 3m from the plant room (LGF where the manifold is), connected by 28mm insulated pipework. The UVC (250l) is in the plant room. Motorised valve switches between heating and DHW. Heating flow goes to the buffer tank (50l), then a pump on the flow to the two manifolds. These have no mixing valves or secondary pumps. All heating pipework is 28mm copper in the plant room, all insulated. About 10m of this on flow and return to furthest (UGF) manifold- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

ASHP outdoor unit heating pump Q

BotusBuild replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

I know you are trying to be helpful on here. There are perhaps better ways of wording some of things you post. e.g. you could have asked what pipe size I used, and sought a better explanation for the pipe layout (which equally I could have provided a better explanation for up front)- 19 replies

-

- 1

-

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

ASHP outdoor unit heating pump Q

BotusBuild replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

Sometimes you comments come across a bit passive aggressive. UGF. Open plan to the left. Large single room to the right. A hall where the small blue loop is shown (but not fitted). A utility and cloakroom where the small read loop is shown (but not fitted). LGF. On the left each loop is a separate room. The 2 large loops to the right are a single room. All pipes are 16mm. No loop longer than 95m as laid.- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

ASHP outdoor unit heating pump Q

BotusBuild replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

Two storey building. Outdoor unit is level with the upper floor. We have UFH on both floors. Lower floor has 7 loops to a manifold. Upper floor has 7 loops to a manifold (in the UGF file attached, the small red loop and the small blue loop to the upper right were left out).- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

ASHP outdoor unit heating pump Q

BotusBuild replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

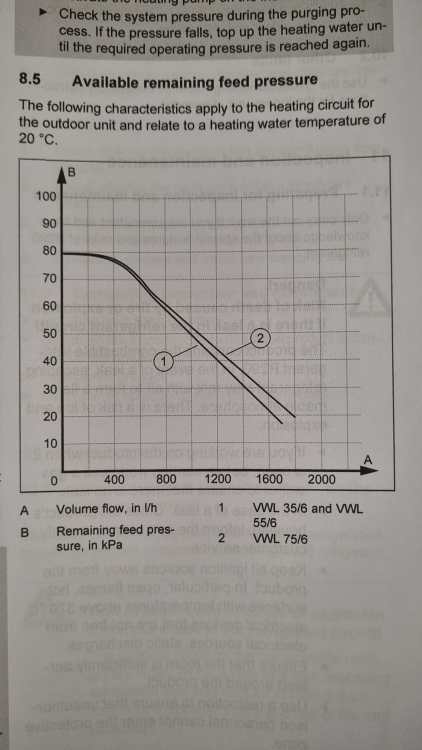

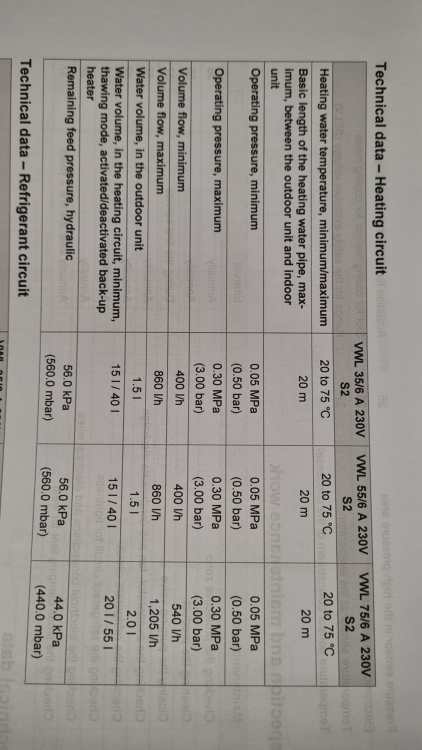

@SimonD 🙂 I tagged it. Its a VWL 75/6. I don't know the index circuit pressure loss. That's a new term for me. Should it be documented somewhere? Possibly called something else? The worst monthh for heat loss for the property is 3246W daily heat loss power for mean min OAT (as calculated using JHarris spreadsheet)- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

I'm looking to remove or bypass the fitted buffer tank in our heating circuit, removing the "extra circuit pump" at the same time. Will the heating pump fitted in the outdoor unit will be capable of circulating the water through the heating and DHW? The buffer tank is 50 litres. The UFH pipes have a volume approximately 100 - 110 litres. Info from docs: The heating pump in the outdoor unit consumes 2 to 50W.

- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

An update. Mrs BB made up a paste of Bicard of Soda and a little water. Applied it to the offending handles with a finger. The washed off with some warm soapy water. Before: After: (dusty at the top due to work I was doing today)

-

@Mr Punter, can you recall what worked to clean the rust?

-

Vaillant ashp (my battle with).

BotusBuild replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

There's one thing about this thread. I've learned a little more about humidity 🙃 -

Vaillant ashp (my battle with).

BotusBuild replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Zoot, Others have answered on behalf. Thanks to them. Agreed that the HW glitch needs sorting first, before you start replacing things that MAY not need changing. Just a thought on the heating. If the VRC700 is inside a closed cupboard with the cylinder, is there enough length of cable (the blue one) to move it just outside the cupboard. That will then be in a slightly cooler place and so it won't switch off the heating as quickly, and before the rads have had more time to warm things up a bit more. This is without making any setting changes so should be a simple to do move. -

Rebuilding after demolishing question

BotusBuild replied to dustyb's topic in General Self Build & DIY Discussion

Guilty, and it was EPS (Nudura) -

Vaillant ashp (my battle with).

BotusBuild replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Hi Zoot, If you follow the directions in that link I sent you on PM, you will be using the Timer setting (not the constant ON), and you will also have setup the daytime temperature and the setback temperature as is being suggested. As per my PM, take the time to read that article, then set aside an hour or so to make the changes. We are all hoping that your understanding gets you to the point of being able to decide to the make the changes. We do all believe it will help in the next cold season. 🤞