Spinny

Members-

Posts

598 -

Joined

-

Last visited

Personal Information

-

Location

UK

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Spinny's Achievements

Regular Member (4/5)

103

Reputation

-

Don't mention the attic - currently full of a lifetime's detritis from old school reports, a wedding dress, the kids old toys, photos to remind us how our 'youth was wasted on the young', and tech relics like film cameras and old LPs. I guess we have turned the attic into a charity shop ;0) https://youtube.com/shorts/2NrNgfoXldk?si=_4T6k6Dz40pxc-B0

-

We are looking to get a new balustrade fitted on the staircase. I am not sure of the ramifications regarding the Newel posts at bottom and top of the stairs. As we are looking at oak handrail and black spindles it would be best to have new oak Newel Posts, otherwise we would presumably have to paint the whole post white or something. Are the Newel posts normally fixed to anything else other than the stringer and stairs themselves ? e.g. into Floor joists. (1930's Semi) I get the impression they gain their rigidity just by virtue of being fixed to the stringer and stair - is that right ? The top Newel Post upstairs runs all the way down to the ground floor. Therefore it seems necessary to cut it off regardless to fit a new top piece onto it from just above the stringer. Not quite sure how you achieve new oak newel posts in practice and whether it is likely to destablilise anything ?

-

Thanks All. The main achievement of the last 3 years has been to transform a domestic house into a small building merchants ;0)

-

Have a load of offcuts of PIR insulation to be disposed of - can I just bag it and take it to the local tip ? (can't see any instructions on their website, and I know they get funny about plasterboard etc.)

-

Plasterboard Fixing Failure at Window Reveal

Spinny replied to Spinny's topic in Plastering & Rendering

Thanks for that. Present thoughts from the guy on site is to use metal frame ties, bond one end (the bent end) to the block wall with resin, and screw the other end into the vertical corner timber. Then fix the plasterboard to that. https://www.toolstation.com/stainless-steel-frame-cramp/p13331 Could do with 120mm length though. And something similar but wider might be easier to resin. (Yes a minor thermal bridge I suppose) Let me know what you think... -

Plasterboard Fixing Failure at Window Reveal

Spinny replied to Spinny's topic in Plastering & Rendering

TBH it started with the builder. I think they just automatically see steels and think fireboard. BC's (often ex builders) can do the same. Seemed harmless enough to do it and save having the conversation. However some places we are using habito which in any case has a decent fire rating. -

Plasterboard Fixing Failure at Window Reveal

Spinny replied to Spinny's topic in Plastering & Rendering

All done with free and open discussion with the architect. I just asked the question and he came up with a way to do it. Yes it was all done with the SE fully in the loop and part of the SE spec and report from the outset. It did require a modest extra steel in the roof structure. It wasn't done throughout, just on one reveal. The brickie's brain nearly melted though. I talk to all the pro's/trades and listen carefully to what they say. Sometimes we go their way, sometimes not. Try speaking to 6 plumbers - you'll get six different answers. Some trades just want quick and easy, they are not going to live there. (Yet strangely some trades will show you photos of their own house with elaborate slow and hard features.) We spent a lot of time over the design because we wanted to minimise any change during the build. -

Plasterboard Fixing Failure at Window Reveal

Spinny replied to Spinny's topic in Plastering & Rendering

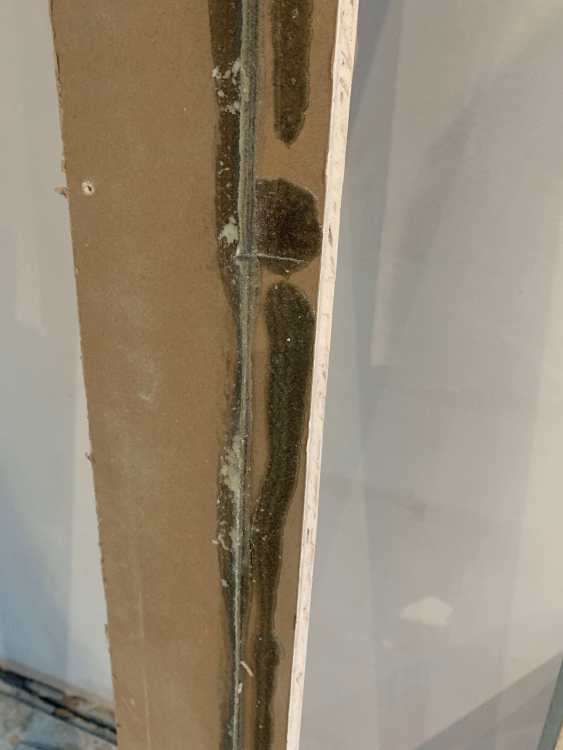

@Iceverge @Nickfromwales @crispy_wafer or anyone The habito face of the adjacent wall section is screwed into the vertical timber at that corner, but on the other side has been fixed to the end of the inner leaf blockwork using PU010 panel adhesive, and the other side/corner just bonded out ready for skimming. We did have access from that side before that which we used to put PIR insulation in the void behind. So it would be gutting to rip that all off again, likely require new board to be cut to size with apertures etc. I was reluctant to put timber against the inside of the outside leaf originally on the basis it would have a lower insulation value, and if by any chance moisture ever made it through the block onto the timber it might rot or mold etc. XPS is strong in compression, but clearly not if you put it in tension. Unfortunately we did the same on another two reveals, so now concerned we will have to redo those with a different solution too. The outer blocks are rendered on the outside face so there is reluctance to start drilling into the back face close to the edge by the window opening for fear of the block breaking out. I don't know if there is another adhesive that would work better. The plasterboard piece to close the reveal seems to need pulling in tight somewhat to stop it bowing out towards the window in the centre. More photos attached. -

Plasterboard Fixing Failure at Window Reveal

Spinny replied to Spinny's topic in Plastering & Rendering

The pencil line shows the chosen plaster line to be achieved, so the plaster board edge will cover the edge of the frame and the 25mm angle would need to be fixed to the concrete rather than the frame. How would I attach the 25mm angle to the concrete block ? It would be adjacent to the edge of the concrete block so screws would be likely to break out. Is there some other adhesive that could be used and be stronger than the resin ? -

@Nickfromwales Here you go... (Looks like carpenter/plasterer guy has a jigsaw blade that will cut the pipe. If we can get the plaster board problem I just posted solved first)

-

Could do with some suggestions on how to fix a problem boarding up a window reveal. The window is 2.4m high running up from floor level. The window has been fixed to the inside of the outside blockwork leaf so that the inside frame is level with the inside edge of the outer leaf. It is an unusual detail as we had the architect remove the inner blockwork leaf so we could have a narrower window reveal. Hence there is no conventional cavity closer. In insulating and boarding the area we decided to fix some 30mm XPS to the inside of the outer block and then also fix the reveal board to this. So we used resin to fix the XPS to the concrete block and resin to fix the plasterboard to the orthogonal edge of the XPS. We used the XPS as it is a good insulator, rather than fix a strip of timber against the outside leaf. The plaster board fixing to the XPS has just failed. And so has the XPS fixing to the concrete block. What seems to have happened with the plasterboard resin fixing is that XPS itself has failed in tension so the resin is still stuck to the board along with a thin layer of the XPS. What seems to have happened with the XPS resin fixing to the concrete blockwork is that it has failed to bond well to the blockwork possibly not helped by some mortar residue on the block. Now the problem is how can we redo this reveal to get secure fixings ? (Especially since the front face has now been insulated and boarded limiting options.) See the attached pics...

-

I am no expert, just a punter like you, and do agree it needs to be re boarded/plastered. It may indeed be revealing to see what lies behind the plasterboard - do take photographs when it is removed. You could consider speaking to your insurers - perhaps you already have. Clearly an insurer will not cover new build building defects. However you would expect them to insist any rectification/repair work is carried out fully and properly including replacing damaged plasterboard etc and replastering/painting. So you could then approach the builder firmly yourself and in addition point out your insurer will also not accept anything else. You should also be asking for the rectification/repair work to be guaranteed by the builder. I would be looking to make sure you have written/email communications between yourself and the builder documenting the problem, the cause, the necessary rectifications and repairs, and the further period for which these are covered by the builder. It may be helpful to have a friend or relative around with more building experience. I have found some builders try to ignore what owners say - I sometimes had to pay our structural engineer to basically say exactly the same thing I had already said to the builder, before the builder would act. (PS If you were selling you might possibly be asked about build defects in a buyers questionnaire or survey, and should be able to give them the guarantee for the rectification work etc.)

-

Could this not be down to the internal circuit design of the light. Some Smart home modules are designed to work without a neutral and others require a neutral for example. Some devices may be looking to draw a very low continuous trickle current to power the PCB and detectors, and direct a larger current or even different voltage to the bulb ?

-

Tad more sun in Pakistan. Must lower the cost per unit of solar power. You are going to aspire to a fridge, a washing machine, and even some air con.

-

Presumably the switch will need to be on all the time to power the PIR detector. The other route these days is to separate the light and the detector wireless smart home fashion. I see there is even a Quinetic PIR detector (battery powered) with adjustable lux level too - Quinetic PIR Link (Not to mention mm wave radar detectors - not sure how well they go outdoors though)