junglejim

Members-

Posts

256 -

Joined

-

Last visited

Everything posted by junglejim

-

No I have PIR between studs then ybs super quilt over the top and battened in place

-

Yes good point… I was planning on lapping up under the ybs superquilt and taping together so would need to do that before adding horizontal batten presumably.

-

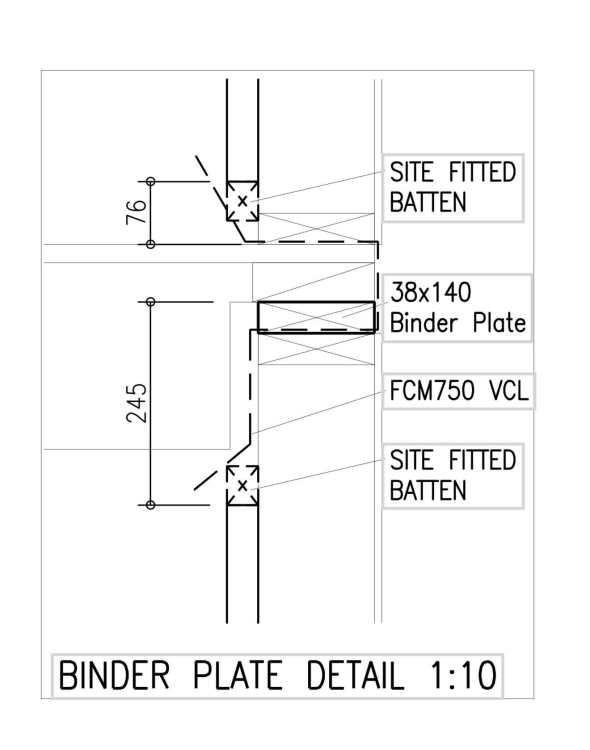

Yes cross section of ground floor to first floor junction

-

Thanks that’s helpful…. Another job the TF sub contractor was supposed to have done but didn’t 🙄

-

I’m looking at this detail in the drawings and noticed the ‘site fitted batten’ I can’t see this but also wonder if it’s necessary as looks horizontal which would surely block the service cavity created by the vertical battens. Given it’s in the eaves I may not need the service cavity. What’s not shown in the drawing is the ybs super quilt under the vertical battens. I’m probably missing something obvious 🙄 Sorry I haven’t got any actual photos as not on site at the moment.

-

Thanks. Would you suggest using both or can the bend supports double up as protection?

-

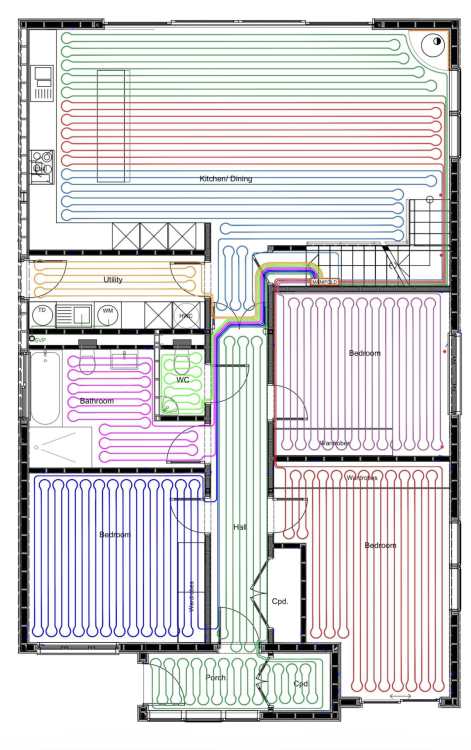

Looking at where the ufh comes through the screed to the manifold. Any tips on protecting? I’ve seen these used; https://www.vpsunderfloorheating.co.uk/product/ufh-90-degree-pipe-support-bend/ but don’t know if I’m better off with some ducting and if so any suggestions? Thanks

-

Thanks. Really helpful. Can I ask why put the yellow behind the upstand when on the other edges it goes in front? I thought it was to decouple screed from insulation etc? Attached is how the other external edges are done where there isn’t a door.

-

Thanks Nick. My logic was because the bottom of the screed is pretty much level with the bottom of the frame so not particularly well thermally protected from the concrete upstand. At the usual wall edges I have a 30mm pir upstand so seems to make sense to extend continue that in front of doors but given its a threshold figured it needs to be load bearing as pir would likely damage. My understanding was that screed needs to go up to the yellow edge strip hence putting that inside the grey foam. Perhaps an alternative is to use pir upstand as per external wall edges but trimmed so that screed can still go over the top but at half depth (3cm) but I’d worry this might be too thin and vulnerable to cracking.

-

Not sure the best way to approach this so advice appreciated. option A: The standard approach as per guidance from screed company is to put the foam edge strip on the door edge and screed right up to it. As per picture A. In my mind that’s potentially a cold bridge point so… option B: I was thinking about putting structural foam perimeter (grey) along the door edge and then the foam strip (photo B) the down side is that the slab will finish inside of the structural foam so the foam won’t have any compression from the slab and the flooring will overlap it. Potentially it’s not very tight and may need trimming down which will be tricky in situ but gives the edge of the slab extra insulation Any advice appreciated

-

Sounds like good logic… but Ufh is only ground floor and fed by the ashp so my understanding was that the ashp would be doing the pumping without need for additional pumps at the manifold. Are there other complaints that will cause significant noise? It’s a timber stud wall so will add acoustic insulation too.

-

@Nickfromwales @BotusBuild @ProDavethanks for the comments really appreciate that and a few things for me to think about. CC are 150mm Manifold: is under stairs. Curious why not there and if you have any other suggestions? Also interested in advantage of going through doorways instead of through stud? Bearing in mind ufh pipe level is above the sole plate here. i can see the logic of removing or reducing the hall loop but presumably that would give me an area with inconsistent temperature/control as essentially following the heat call from the rooms. Given its low temperatures run off ashp this may not be a problem. Just seen pro Dave’s comment… makes sense. re the wood burner… slight bone of contention between me and my wife! But… will be externally fed and aiming for something with good heat retention to provide slow release heat. glad I asked the question as would have likely blindly followed the plan. I’ll go back on Monday with some questions.

-

Week 15 - UFH, screed, and render base coat

junglejim commented on Benpointer's blog entry in Contemporary build in north Dorset

Just curious how you sealed penetrations where ufh went through the stud… presumably run through a sleeve and then expanding foam? -

I’m getting close to being ready to install ufh. A local company has completed a design but I’m wondering whether I should go back and request a spiral layout? The ufh will be run off ashp, the screed is liquid (ecoscreed) and build is timber frame and aiming for good airtightness etc. i could be overthinking so looking for advice before going back to the company on Monday. Thanks

-

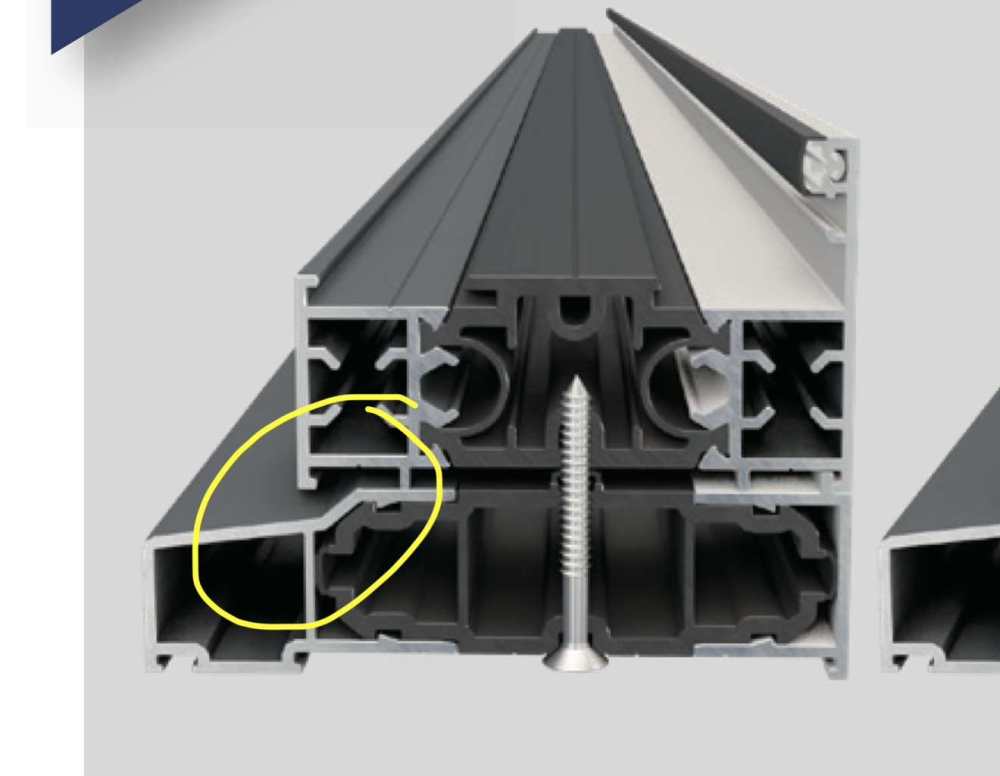

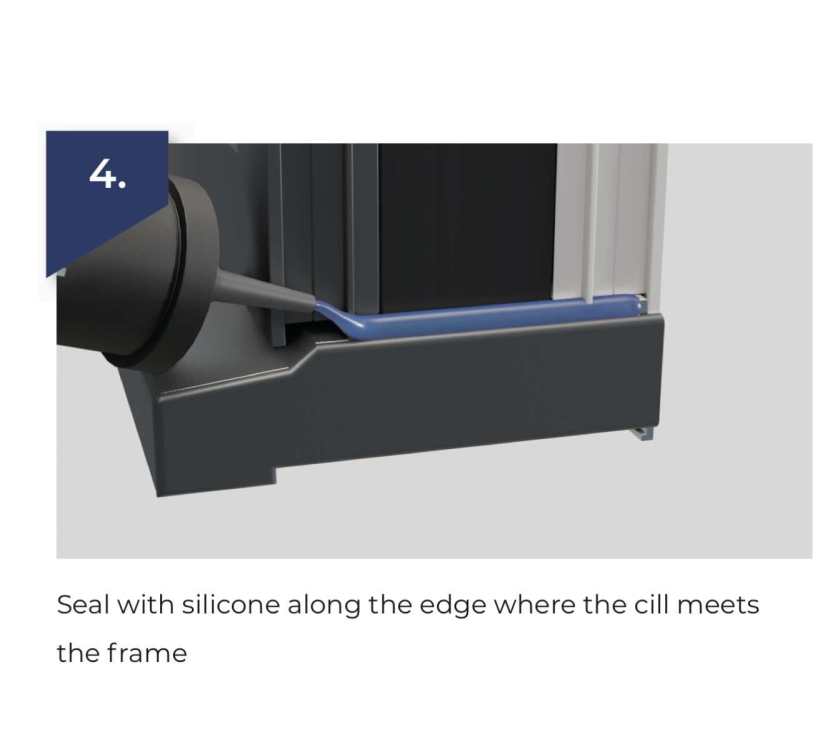

Thank you that’s helpful. Are you pointing to the groove in the window frame? One theory I have is that it’s getting in through the joint between frame and cill as circles in attached. Adding sealant where you suggest could be a solution.

-

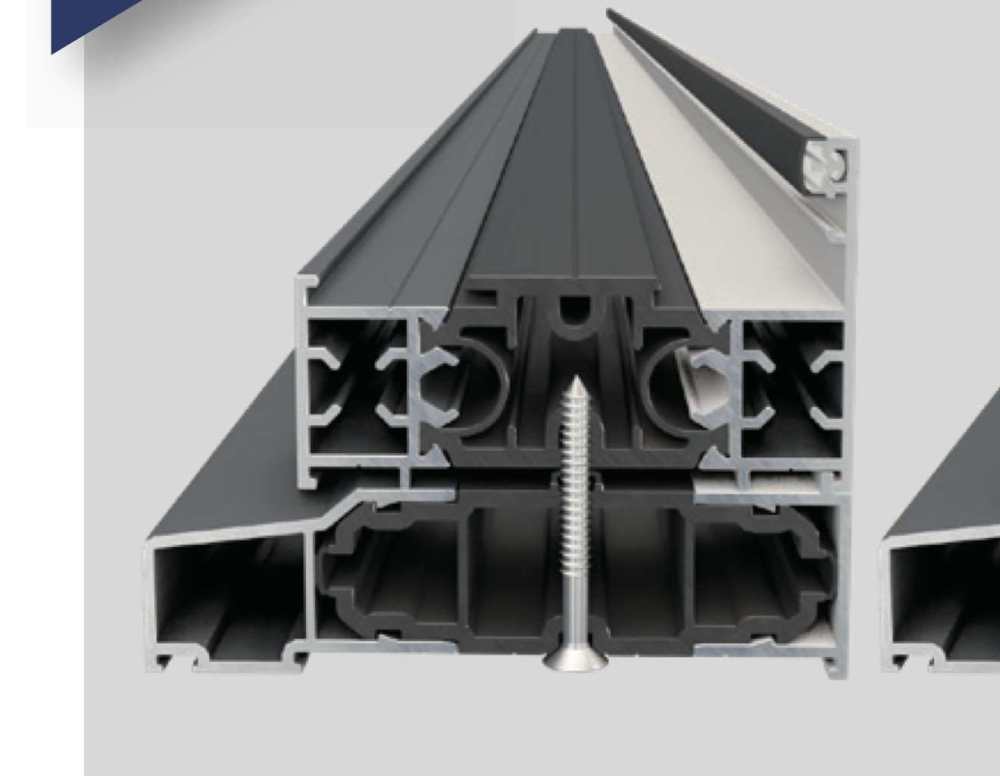

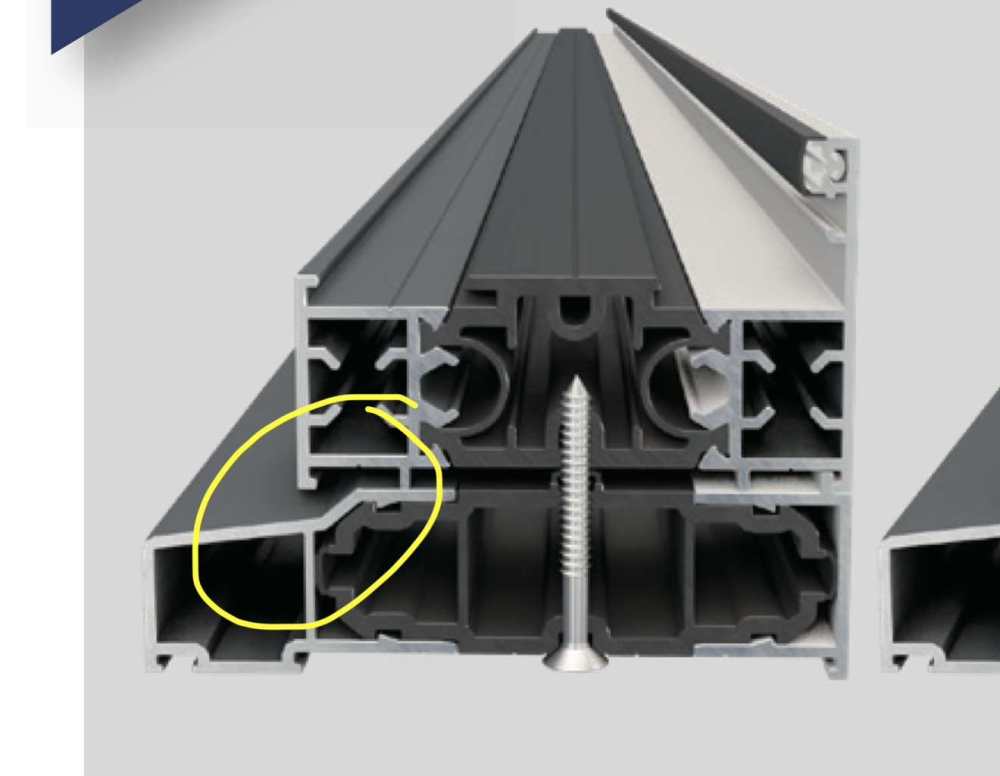

That looks neat. The cill and frame were fitted together but manufacture details show it as 2 parts. (See attached technical drawings) There’s no upstand though… that’s looks neat but not something on mine.

-

Yes taped with tescon vana

-

So… we survived storm Goretti (just!). With torrential rain and driving winds of 90mph+ it was a pretty extreme test of our build. Having got through other storms and downpours unscathed I was uncharacteristically optimistic but… frustratingly 3 or our windows have some water ingress at the bottom corner. The windows are Prestige Sheerline. The cills overhang the cladding well and underneath is dry but the wind has blown hard pushing water into the lower right hand corner. I think my cladding reveal had been too tight to the cill and trapped water as seems quite waterlogged but… around the window I used compriband expandable tape and Tescon vana so should be well sealed. I’m a bit stumped how the water has got in but one possibility is through the end caps of the cill… (edit: on second look I don’t think that’s possible as the cill ends extend beyond the opening.) one other possibility is that the water is being blown into the drainage area and sloping to the ends… according to prestige this should be sealed with silicone (see attached) and I can see some silicone but there’s no way of telling if it’s failed. I’ve added some manufactures pics but thinking it’s likely to be something I’ve done rather than manufactured but there was a lot of debris blown and washed into the end if the drainage area highlighted on one of the drawings so a lot of water has been pushed this way. i realise that 90mph and torrential rain is extreme but I’m off the opinion that water shouldn’t be able to get in and would like not to have to worry about this in future. The attached image is from ‘clevett’ video (not mine) but similar to my finished result. Any tips/suggestions etc greatly appreciated. The stress of self building is definitely showing in my hair colour!!

-

Week 15 - UFH, screed, and render base coat

junglejim commented on Benpointer's blog entry in Contemporary build in north Dorset

Really useful post. Thank you. Any chance you can share a close up of the detailing at the bottom corner of your windows externally where there will be cladding…. Just had a set back on our build… thought we were watertight but 90mph winds and torrential rain means water had found its way in at the bottom corner of windows. I thought I’d sealed/an everything well but think I had the cladding too tight to the cill so water couldn’t drain underneath. Still unsure what route it’s taken behind but interested to see how others detail this. also… did you cut out studs in doorways? I have a sole plate with stud base plate ontop so essentially double sole plate internally. I’d like to cut out the top one in doorways so that I can run insulation and ufh and screed through easily. Thank you -

Thanks that’s helpful. Hoping I can switch the apron out without taking out all of the tiles around the window. Keeping fingers crossed that just the lower ones will be ok. struggling to bend the edt back into position so may need to replace those too but would rather not if possible so any suggestions would be welcome. Also wondering if there’s any way to improve the overlap at the edges. moving the tiles across the whole roof isn’t an option but maybe some kind of metal strap screwed into the batten and extending over the apron. Thank you for all the advice. Racking my brain here trying to figure out solutions so any experience/advice very welcome 👍

-

Advice from VELUX is that I need more overlap with tiles at the ends to hold it down. With these interlocking tiles (Sandtoft new rivius antique) and the wide gauge in not sure how to achieve this or whether there is any kind of workaround. Any advice greatly appreciated. Thank you

-

All of our velux aprons have damaged in the storm. One has sheared off completely (the malleable type for tiles EDW). We have some others that are flat which I thought would be better but are bent upwards and won’t reshape into position. Any ideas and best way to fix and long term solutions? ta

-

Thanks… that was my gut feeling. Do you think good above both?

-

Thanks for the reply. This is an internal stud wall on timber frame build. Raft slab. No dpm under the slab. Will lap up external walls but no bed on internal stud as within the envelope but had wondered about taping to the dpm strip under the stud. Have read that overlap alone is sufficient though hence confusion. ta

-

Argh I’m overthinking this so could do with some advice. Here’s a photo of my internal stud wall with dpm strips underneath. I was going to lift up the thicker black dpm and lay my floor dpm with double sided tape between the 2 but thinking now that it’s probably better to lay the floor dpm over both? I’m also unsure whether taping is needed or the overlap is sufficient? Paused mid job to think over a brew so any advice greatly appreciated. 👍☕️ @nod@Nickfromwales @saveasteading