lookseehear

Members-

Posts

160 -

Joined

-

Last visited

Everything posted by lookseehear

-

This makes sense, but there's no 'courses' like there would be with brick/block, although actually looking at the picture of the crack, the mortar lines aren't as misaligned as they could be. How deep does this need to be to be effective? This house has been knocked around quite a lot in the past I think. It'd be very hard to establish beyond guesswork I think. Thanks for this - I'll look into it.

-

Our SE isn't interested in specifying this - any tips for finding one that will? Am I looking for someone who specialises in old houses or should any local SE be able to assist? I'm nervous about someone over-specifying in this situation because I genuinely believe it hasn't significantly moved in the 5 years we've been here. When I said plastering I meant lime plastering (lime putty hemp mix from Ty Mawr) rather than gypsum. I've also been plugging any bigger holes with a premixed lime putty mortar and stones as I've been going. In this case is there any risk of encouraging more spreading by filling the gap? I get the bars from your picture - they look like they're effectively chased into slots then secured with resin? How deep are they chased in? Is the plate similar to what @ProDave is suggesting? flat to the front of the house and tied into threaded bar embedded deep into the stonework? When you say 'well away from the gap' I'm not sure how that would work - for it to pull against anything it would need to go something like this wouldn't it?

-

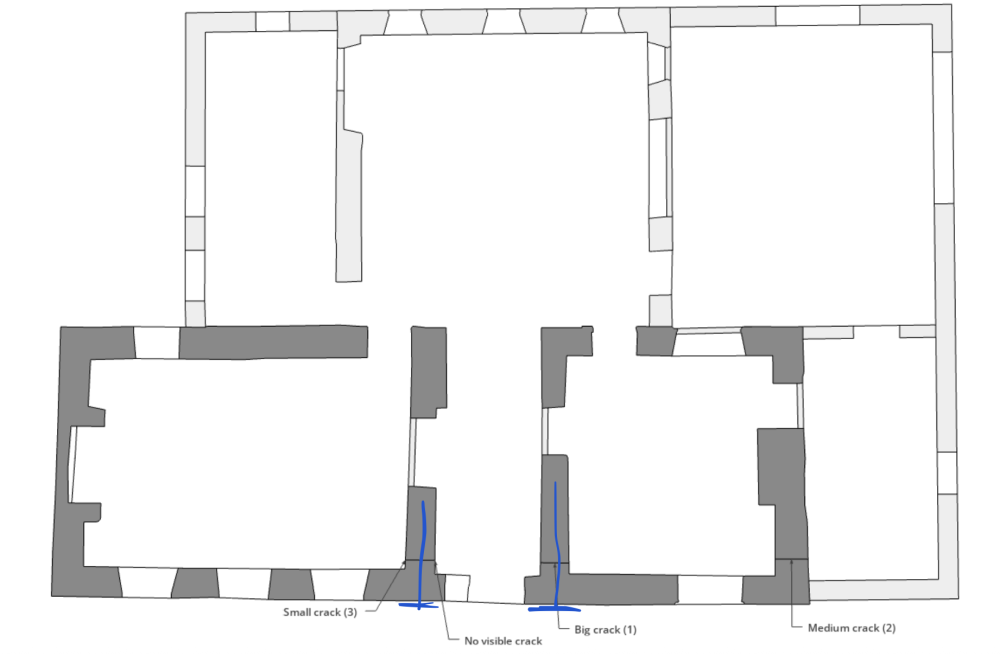

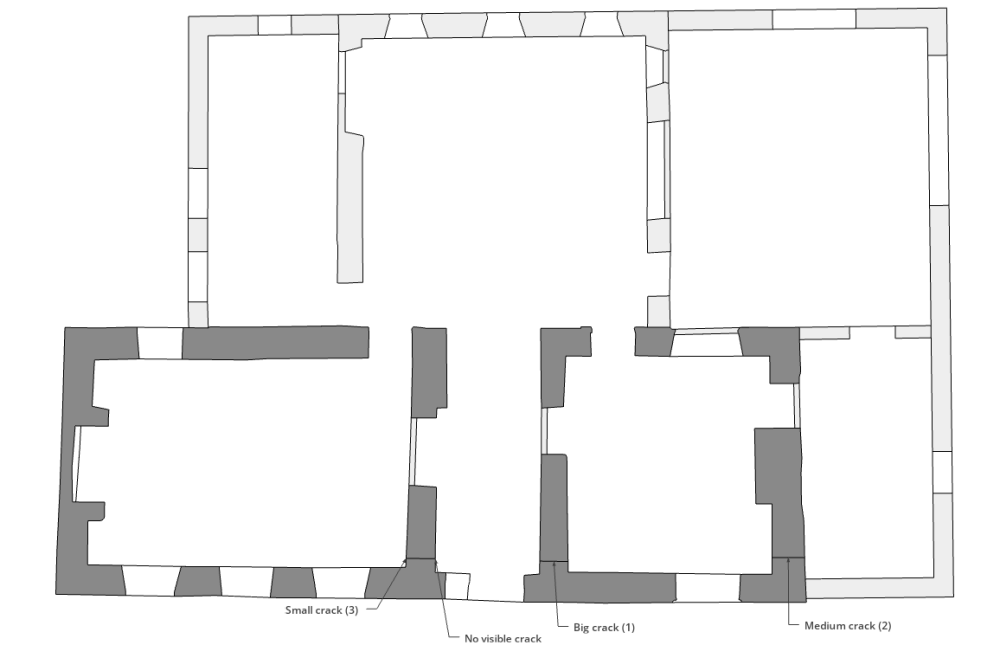

We've recently moved out of our renovation/retrofit and that's meant more of the old fabric could be removed. We took the old kitchen out which had been there 30+ years and there's a significant crack in the stone wall behind where some cabinets and tiles were located. the most concerning aspect of this is that there's a similar but less significant crack in the wall opposite which would indicate that it's the front wall of the house that's leaning outwards, and before I plastered I noticed another even smaller crack on another similar wall. Hopefully the pictures below help to illustrate the problem. I've numbered the cracks 1 - the big one, 2 - the one opposite in the same room, 3 - the smallest one. Old walls are dark gray, newer walls are light gray which are a mix of 1970s concrete block cavity walls and new cavity walls. I've also put an arrow to 'no visible crack' which I've included a photo below. This plaster has been there a long time - probably 40-50 years I'd have thought and it hasn't cracked or shown movement. Here's a picture looking at the corner of the house before we constructed the new extension which is the outside of crack 2. Nothing significant from outside and that corner is now abutted by a deep foundation and new cavity wall. Upstairs the new roof is supported on a series of steel (upside down) V frames with a steel ridge, so any 'spreading' forces should be limited. after discussing with the builder, we asked the SE about whether it would be a good idea to cast in place a reinforced concrete 'ring' beam along the front of the house to resist the wall from leaning out any more. The SE said it wouldn't harm, but also wouldn't be drawn on whether we should or shouldn't do it, so that's our current plan. It doesn't feel to me like this crack has moved much in the recent past, but I'm also aware we're doing significant structural work here. Is there a common solution for holding together old buildings like this? Thank you in advance.

-

Timber frame infill over cavity wall/steel lintels

lookseehear replied to lookseehear's topic in General Construction Issues

Aiming for ~100mm of Knauf Omnifit above it. I'm fully filling the rafters with 150mm Omnifit and I'm hoping it will be not too tricky to get around the ridges and junctions. -

Timber frame infill over cavity wall/steel lintels

lookseehear replied to lookseehear's topic in General Construction Issues

Padstones both sides, but on the left there's another column of blocks because the opening was the wrong size initially. -

So this means that if you had an ASHP on one phase pulling in 8kW and a battery on another phase exporting at 8kW, you'd effectively be saving at the current per kWh rate because they'd offset, but if you export for an hour, then run your ASHP for an hour you'd export at the export rate (eg 15p) and import at the current rate (which could be 28-30p/kWh). Unless the system is tuned to import to the battery when electricity is cheap, then export to match usage during peak hours you would be losing out financially.

-

OK I think I'm understanding the metering aspect, with import and export netting off, but does that play well with time of use tariffs? If I am exporting from the battery in the evening, but drawing from the grid during the day to run heating, those things won't surely net off in the same way that running the ASHP from the battery would do? We're a bit limited on the size of our solar array because only one aspect makes sense and it's low pitch (30 degrees) which means that the max we can squeeze in would be 5-6kW peak. I was hoping to put in a large battery with scope to increase capacity in the future so that during the winter we're minimising running the ASHP off peak rates (eg using Octopus Cosy to top up the battery).

-

Timber frame infill over cavity wall/steel lintels

lookseehear replied to lookseehear's topic in General Construction Issues

Thanks - I like this idea. I assume I'd need to get the SE to confirm it's OK before we start drilling holes in the top flange, or am I OK if the holes are small and not drilled in the web? -

We're moving our electricity supply and National Grid said they only put in three phase in this situation. I initially was quite pleased about this - it felt future proof. I'm now looking at solar and battery combinations, and installers seem less experienced with three phase systems and the cost seems higher. There's the benefit of being guaranteed ~12kW export balanced across the three phases. We're also planning to put in an ASHP and I assume that we would now need to put in a three phase ASHP to spread the load over the phases, and again there looks like there's less choice and potentially more cost involved. It feels like going three phase has added cost and complexity at this point. Is it possible to run it all off one phase or push National Grid to put single phase in? It feels like an own goal with three phase to not have the heat pump and battery on the same phase, but then the system will be out of balance. Am I missing something or does it all have to be three phase to play nicely together.

-

Looking for some assistance with a detail: Need to infill above this window on gable end (lintels are steel beams on inner and outer leaves). The builder doesn't want to use masonry because it won't tie into the steel and he thinks it's just going to end up unsafe. He suggested timber frame, but I guess it would need to be strapped down, which is again problematic over the window. If we go with a timber frame, do you think straps either side of the steel would be sufficient? Timber frame just on the outer leaf? or on both? Any alternative ideas?

-

Any love for CCT (i.e. changeable white) LED strips?

lookseehear replied to Alan Ambrose's topic in Lighting

I’m looking at using ‘dim to warm’ bulbs which get warmer as they get dimmer, meaning you can get controllable white temperature but without from a regular dimmer switch. my current plan is to put zigbee dimmer controllers behind retractable push button switches so that they function as regular dimmable lights but with the option to create scenes as well. -

Couldn’t you have your tilt fillet a bit back from the fascia so that it’s taking the weight of the slate?

-

Not sure if you've solved this yet but I don't think having a tilting fillet stops you doing over-fascia ventilation. See the below from LABC.

-

You're right I'm probably looking at this the wrong way round. I'm likely being swayed by the fact our current EV only has a 24kWh battery and needs charging often and sometimes during the day, whereas most newer EVs have bigger batteries and can be charged overnight almost all of the time. There are definitely times during the day where someone would want to 'top up' an EV with a larger battery, for example just before a long trip where you want to have max range to start with. The issue with using the car battery to buffer the house demand or grid is unnecessary battery cycling - no one will want their car battery devalued or degraded. But I agree that having an 80-100 kWh battery sat on the driveway seems a bit of a waste if you can set it to better use.

-

It's really hard to tell whether these things will happen at the same time. Low overnight rates is a product of low demand vs peak hours, but I don't know how much more the adoption needs to increase until it becomes relatively higher demand and therefore has a cost impact to the consumer. The good thing is demand is predictable and relatively stable (and growing) which I think will contribute to keeping prices lower. Solar's problems are that it's seasonal and unpredictable and peak generation is rarely when consumers want to use it. Without the demand from consumers, it's more likely to be that we see a lot more 'free' energy during the sunnier seasons to balance the load, which will likely have a greater impact on the feed in rates because you can only buy something for 15p and sell it for nothing to a certain point. My guess is that feed in rates will drop before overnight rates increase, but who knows. I'm not proposing to dump all the power from the battery into the car, but I'm thinking that with some moderate sun it would make sense to supplement solar production with a battery for a short charge during the day.

-

My understanding (happy to be corrected) is that if I have a fully charged 10kWh battery and a 5kW inverter, I can only draw 5kW from the battery. This would mean that if I plug in my car to the 7kW charging point, I would have to 'buy' 2kW from my electricity supplier rather than use what I have in the battery. Another scenario is that it's full sunshine and the panels are generating 5kW and I plug the car in, I can't do 5kW from the panels and 2kW from the battery without a bigger inverter. I believe the panels and battery are DC, but the inverter is required to convert to AC for use in the house or for selling back to the grid.

-

Maybe I need to look more at tariffs. My assumption in the future is that export rates will reduce as more people get solar, because they'll all peak at the same time and at that time the generation will greatly exceed energy requirements. Other than being future proof, why look for a system which doesn't require internet? I imagine internet is only for some smart features, not for basic functionality? the one who offered 3 or 5 said the 5 would be a 'small additional cost' and the 8kW one didn't mention but I assume would get consent as part of the install. In the event we want to charge during the day (and if we have 2 EVs that might be more of a common occurrence), it would make sense to use stored energy in the battery wouldn't it? If I have a 3kW inverter and charge at 7kW I need to import 4kW from the grid at peak rates. Sorry if I've misunderstood. Not sure I agree - charge at 7-8p/kWh, get ~3miles/kWh efficiency means ~2-3p/mile plus 3p new tax still makes it probably half the price per mile of a petrol or diesel. Things will change though over time. Personally I hope someone manages to reform the UK energy market to enable cheaper electricity from renewable sources.

-

I've had a couple of quotes for solar + battery + associated hardware and have three options on the table. We're looking at a 5kW array and probably a 10kWh battery. The options are SolarEdge or Libbi from one installer, or GivEnergy from another. The main difference that I can see is the first installer is offering a 3kW or 5kW inverter whereas the GivEnergy is 8kW. We have a small EV but we'll likely get a bigger one when all the work is done, so I'm leaning towards the GivEnergy. We're also expecting to put in a 10-12kW heat pump as part of our renovation and a >200l UVC. We're on Intelligent Octopus Go at the moment with a SyncEnergy 7kW charger, which I'd rather not replace but would do if it meant managing the whole system was easier. I'm not really sure how I'm meant to choose between these three options. Are there any obvious good or bad choices here? Ideally I'd like a system that can manage import/export, dump excess solar into EV/DHW and be as future proof as possible.

-

Using multifoil under steico insulated roof

lookseehear replied to lookseehear's topic in Heat Insulation

It’s a brand new roof, so it’s actually less of a retrofit. Rafters are 150mm. i think you’re right that the risk is higher, I just can’t work out how much higher and if it’s allowable by Recticel etc then maybe the risk is mitigated by decent breather membranes and a small amount of ventilation from counter battening and not having the insulation jammed against the breather. -

Using multifoil under steico insulated roof

lookseehear replied to lookseehear's topic in Heat Insulation

Any thoughts here? -

Using multifoil under steico insulated roof

lookseehear replied to lookseehear's topic in Heat Insulation

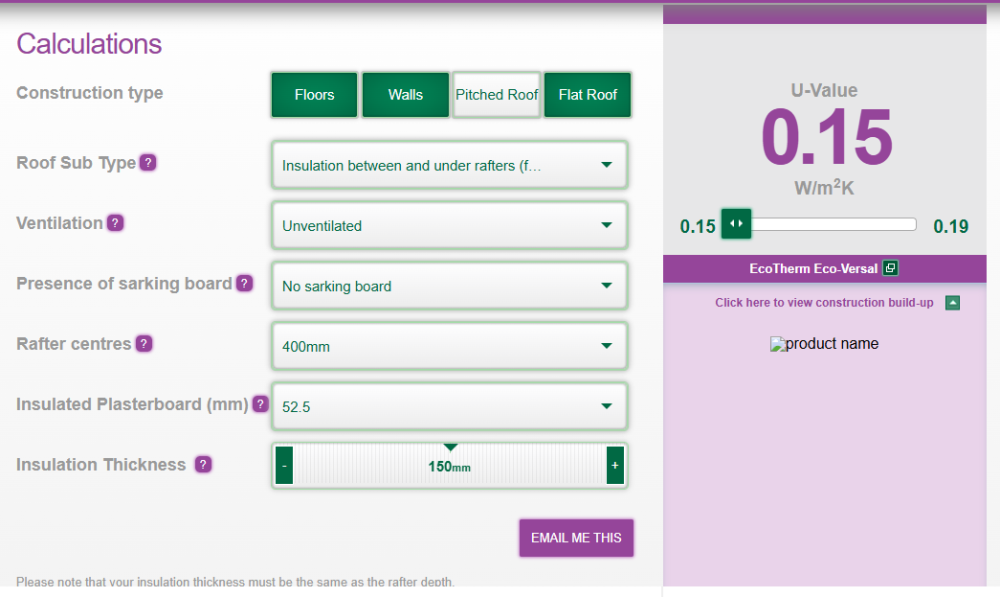

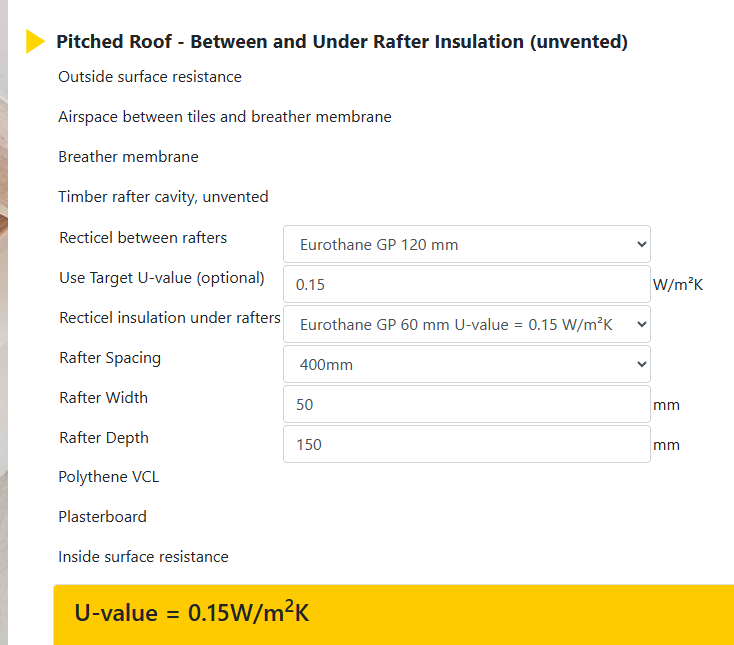

I've checked with the SE and no sarking board or 'racking' layer required. I'm thinking about taking the simple route here and going with PIR between and under the rafters. I've been on a few websites (ecotherm, recticel etc) and they seem to indicate that a 50mm ventilation gap isn't required providing a breather membrane is used, but that maybe you need to leave at least 25mm of rafter 'unfilled' and potentially counterbatten as well. Ecotherm calc below showing 'fully filled' with 150mm PIR, with 40mm underneath to get to 0.15, and Recticel only showing 120mm in 150mm rafter. Is going 'unvented' a bit of a risk or are modern breather membranes combined with a good VCL underneath sufficient to ensure no risk of condensation? -

Long hot pipe runs (second HW cylinder?)

lookseehear replied to lookseehear's topic in Bathrooms, Ensuites & Wetrooms

Thanks for the response. I'm really hesitant to move the DHW cylinder - we've got a dedicated plant room already constructed and drains in place for bathrooms. I like the idea of a manifold and will have a think on that. I'm not that keen on the smart plug idea - they always feel like a good solution to short term problems to me, and I don't want an Amazon device in my house. Given the complexity of the job (heating included) I'm leaning towards speaking to a local HeatGeek certified installer (potentially under their 'black label' service) for the heating and DHW plumbing. -

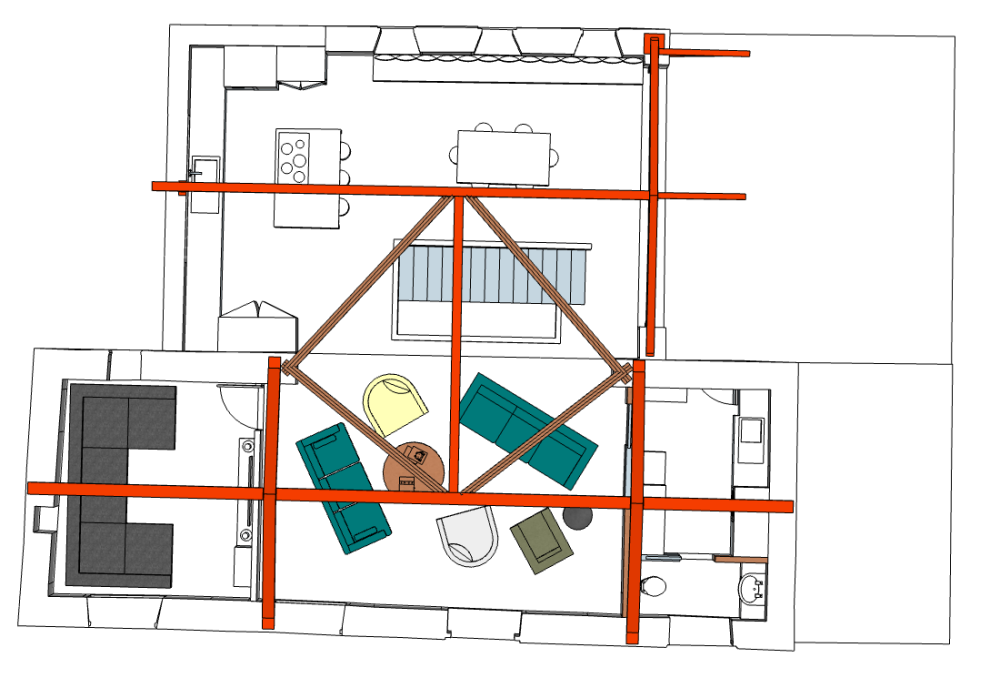

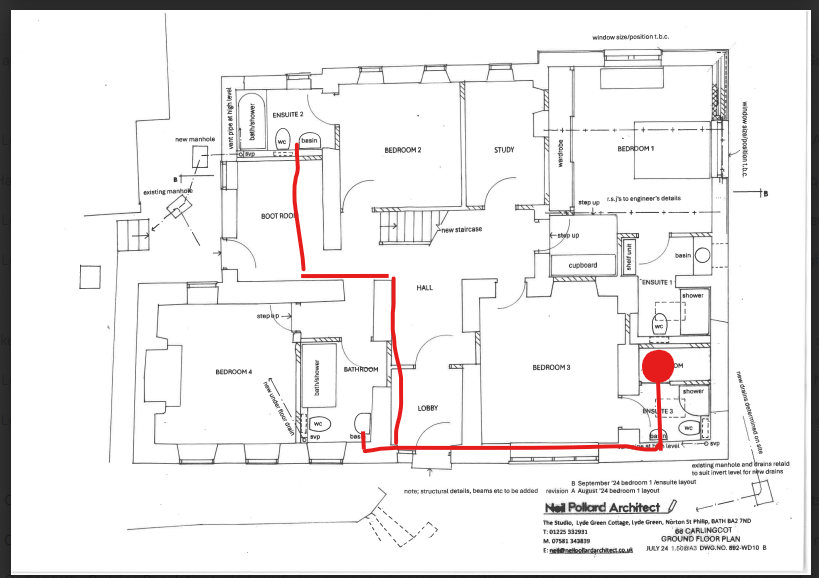

We're starting to plan pipe runs for new bathrooms in our extension/renovation project - as a reminder everything is moving around due to going upside-down and house is being rewired/replumbed. DHW cylinder is going in a small plant room in one of the new extensions which is on the corner of the house. In total the hot water requirements are the kitchen plus 3 shower rooms (ensuites), one 'family' bathroom mostly used by guests and one small WC. The bathroom layouts in the below sketch are not correct, but the room positions have not changed. The red circle is DHW cylinder and the red lines are likely HW pipe runs to 'family' bathroom, ensuite 2 (shower room) and the kitchen which is above the boot room and Ensuite 2. I had assumed we would run 22mm for all the main pipe runs and branch off to 15mm to maintain flow, but I've now realised that in the kitchen that could be a 15m+ pipe run in 22mm and would take half a day for hot water to appear at the tap, and the same problem in ensuite 2 and (to a lesser extent) in the family bathroom. What I want to try and avoid is the shower in bathroom 2 being severely affected by the kitchen hot tap being used. I know that we won't be able to use all the showers simultaneously, but I'd like to be able to use any two at once. I can see a few solutions but maybe there's one I'm not aware of: Use 15mm instead of 22mm from where the pipe branches off near the front door to the back of the house to serve the kitchen and ensuite 2. This would lessen the delay overall, but with less more restricted flow to the back of the house, the shower would be more likely to be impacted by the kitchen tap? Run two 15mm hot branches (or one 15mm and one 12mm) from the 22mm running along the front of the house to the back of the house. the 15mm just to the shower in ensuite 2 and the 15mm/12mm to the kitchen tap and ensuite 2 basin. This might isolate the shower from the sink more effectively and reduce delay for hot water to the kitchen/ensuite sinks. A second small hot water tank with an immersion under the sink to feed the kitchen hot tap and the hot tap in the shower room and run 15mm from the front just for the shower in ensuite 2. This would decouple the kitchen from the ensuite shower and mean close to instant hot water at the taps in the kitchen and ensuite. I've seen the heat geek mini store and wondered if I could put that in a corner kitchen cabinet in addition to the main DHW cylinder in the plant room. The mini store could run the kitchen and the ensuite shower/taps. I've no idea if this is even possible - planning to put in an ASHP as part of the building work and don't know if/how it's possible to run two cylinders on opposite sides of the house in parallel from one ASHP. i know I have a tendency to overcomplicate things, but unfortunately that's just the way my brain works - I'm thinking through all the options at the moment. Any feedback?

-

Fine tuning my IWI Solid wall (Warm Batten) design

lookseehear replied to Annker's topic in Heat Insulation

I just wanted to pick up on this point. It's often not useful to compare internal and external RH's because of the temperature difference. You may know this already, so sorry if I'm teaching you to suck eggs! 95% RH at 15 degrees is roughly 70% RH at 20 degrees, which is why opening windows to allow colder external air in is almost always going to help dry a house out. If your internal warm air is 95% RH then that's much more likely to be a sign of a problem (water coming from another source). I've lost count of the amount of times during the winter I've seen people posting online saying that they won't open their windows because the weather shows it's 100% humidity outside, when in reality 100% humidity during a cold spell will give lovely dry air once warmed up to room temperature.