-

Posts

131 -

Joined

-

Last visited

Everything posted by AppleDown

-

DPM External Flap - what to do with it?

AppleDown replied to AppleDown's topic in General Construction Issues

The detail just shows what most do - DPM just ‘finishes’ directly after the soleplate. -

DPM External Flap - what to do with it?

AppleDown replied to AppleDown's topic in General Construction Issues

My thinking was more along the lines of keeping a sealed envelope. If I lap down, the opening between the DPM and soleplate is exposed. If I lap up (and do it properly) then the envelope is sealed - better airtightness and less chance of water ingress. Double sided tape (butyl) between DPM and mebrane, staple through, then tape fully over the top of DPM to form a complete seal. -

DPM External Flap - what to do with it?

AppleDown replied to AppleDown's topic in General Construction Issues

Will grab some better ones tomorrow but here’s a hastily cropped and zoomed version. The buildup on top of this includes Actis BoostR Hybrid - for insulation and airtightness. So ideally the DPM gets lapped up, taped, BoostR stapled and taped, battened, and then clad / render depending on area. -

Hello everyone. I’m doing a few ‘keep busy’ jobs over the next week until my crew are back on site. One of them is tidying up the DPM flaps that are hanging everywhere. My build is timber frame, over blocks on slab. DPM is between blocks and soleplate as per usual - and currently extends out anywhere from 15cm to 40cm. What should I do with this? Original idea was to lap it up the breather membrane on the OSB (DPM flaps cut to a uniform length first) and then tape. Is that just the standard detail?

-

Windows delivered - wrong internal finish/colour

AppleDown replied to AppleDown's topic in Windows & Glazing

Just as an update and close out of this - we agreed on a 30% refund. Happy with that, and we can paint some of them white (warranty won't be affected). Cheers for all the help. -

Windows delivered - wrong internal finish/colour

AppleDown replied to AppleDown's topic in Windows & Glazing

The confirmation was after the signed order - BUT there were other additional amends that were actioned after the signed order, such as sizes, amount of windows, and then the addition of cills. All done with the same person over email. From what I can see that removes the argument that the request was after the signed contract and in direct communication with one individual - and not through any specified 'changes@...' email. I'm going in hard this AM and asking for 75% refund, and we'll live with them (and maybe paint a couple white if we can). -

Windows delivered - wrong internal finish/colour

AppleDown replied to AppleDown's topic in Windows & Glazing

As they're aluminium clad, it should just be the aluminium portion that's grey - it would probably end up cheaper by not painting them. -

Windows delivered - wrong internal finish/colour

AppleDown replied to AppleDown's topic in Windows & Glazing

Correct, I believe there would be a clear coat - my comms just referenced 'plain wood' compared to painted. It's a super smooth finish, so I would expect that they need to be sprayed. So glass etc. protected, sanded down, sprayed. But it'll be a big job. Happy for them to do that, but just trying to understand what my moves should be... At the moment it sounds like the best strategy is to say we don't want them and that it wasn't what was ordered - so either you take them all and make good, or you fix the issue and compensate us for the trouble. -

Windows delivered - wrong internal finish/colour

AppleDown replied to AppleDown's topic in Windows & Glazing

Thanks all. I think it's a bit hazier than I originally thought. @craig and @Nestor this is where it does get a little confusing. The initial signed contract order form mentions the grey RAL for both internal and external - BUT, the conversations around this (and within the email chain where this was returned) clearly state that internal is TBC and will be confirmed. It is then confirmed with the same Sales rep a week later in an email he sent me requiring confirmation of our choice, and then acknowledged that this would be sent to the surveyor and amended. At no point during any of our conversations prior to or after the contract did we ever say we wanted grey internally - and in fact, we clearly stated we wanted plain wood or white washed from the very first email conversation. In addition to the confirmation on colour - the same email also contained confirmation of in/out opening, hanging side etc. which was clearly taken on board as those are correct in what they have installed. I'm sure they will do everything possible to highlight the signed document as confirmation - but the specific requests and replies from the Sales rep in my eyes forms a confirmation of change. -

Hello all. Been a long time since I updated you on our build. We have just taken delivery of the windows - I'll not mention the company at the moment, but they're Rationel AURAPLUS (ali clad timber, triple glazed). We were very clear with the company that we wanted anthracite exterior (on the ali clad portion) and internal we wanted a plain timber finish so we could oil/stain/paint whatever colour we wanted. Every conversation we had with the sales person taking the order mentioned this, and at no point have we ever said we wanted anthracite on the inside (only ever plain or washed white). They turn up yesterday and it's solid anthracite both external and internal. I've checked back through our comms and the initial contract with the details - this didn't include a specific reference to the internal colour, as it was clear in the email comms with the sales person we hadn't decided, only external colour being anthracite. We then followed up with the sales person two weeks later to confirm the internal colour preference - non-painted, plain wood. In fact, he was the one who reached out to us - and then he confirmed in reply the colour choice and stated they would inform the surveyor too. At that point the surveyor attended site, took measurements and confirmed that. From then on there was no further request for clarification on colour etc. Where do we stand? I've raised it as quickly as possible with them, and they have replied on email stating they will look into this ASAP. I would assume that because it's clear in the comms what we wanted and confirmed by them, that we're in a good position. They are obviously not going to want 20+custom windows returned.

-

We're using Forma composite cladding, and that can come in Class B. Also just a quick question - is there a reason you're doing render on block with the timber frame?

-

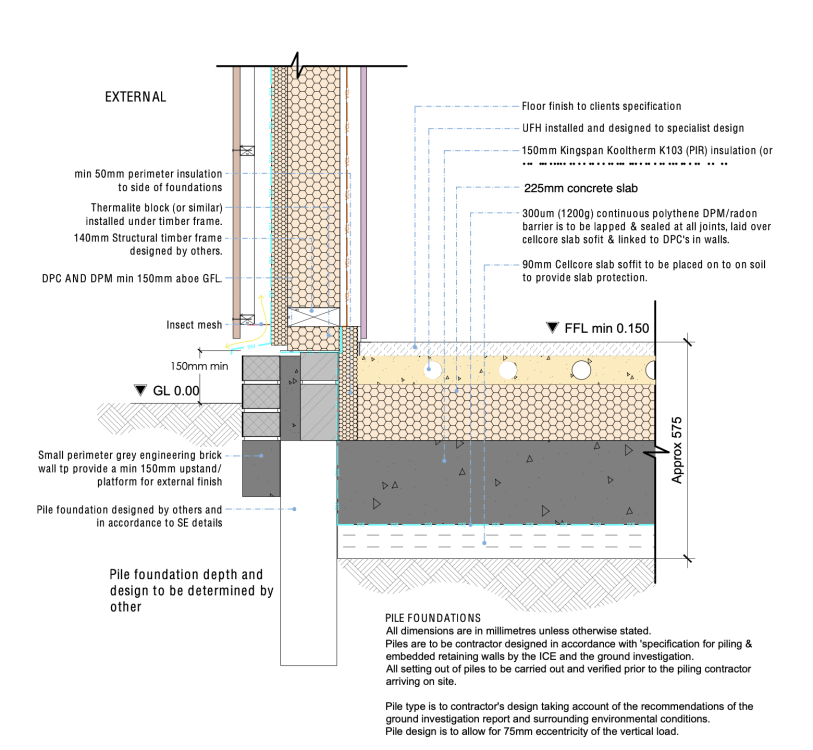

Does this make sense? Piled raft cross-section

AppleDown replied to AppleDown's topic in Foundations

It definitely needs piles. GR has been sent off to about 10 different people - including AFT and Tanners, and all suggest it either needs replacing down to 2.5 metres with new ground, or piles. Piles is easier and cheaper. The design for loadings has been done, so they know where and what depth to place them at. I'm just trying to work out if that drawing makes any sense - as my understanding is based on what's on the forum and what an initial part-time PM is telling me. If the slab extends further, is that all that needs looking at - or are there other glaring mistakes? -

Does this make sense? Piled raft cross-section

AppleDown replied to AppleDown's topic in Foundations

Sorry, that's just me using the term - can call it slab. As above - if the slab extends to under the supporting dwarf wall upstand, is that then correct? Where does the DPM meander through? -

Does this make sense? Piled raft cross-section

AppleDown replied to AppleDown's topic in Foundations

I totally understand the piles and slab will be designed by a SE who knows what they're doing (that's happening at the moment), but in the actual details of what's shown for the slab to wall junction, and how it's supported - are my assumptions correct? If the slab extends to under the upstand blocks, is that how it should look? And if so, what's the route of the DPM? -

Looking at the cross-section we have from our Architectural Technician for our piled raft. Before I go back with questions - his inclusion of a 'pile' on the edge of the concrete makes it look like the timber frame is floating on nothing. Am I right in thinking the raft needs to extend under the timber frame wall and dwarf block wall, and then add some insulation outside of that? Also, what does the DPM do? Then you have the perimeter build up next? Or am I taking crazy pills?

-

Hello all. We've well and truly started our excavation and access changes. But today we've unearthed a little surprise. The digger driver I bought in to help discovered an old 75mm water pipe running straight through the middle of the potential foundations. Quick tests seem to suggest it's at mains pressure. It runs from the south end of our plot, coming from a private school. We have yet to see where it goes to. We managed to speak to someone from the school by chance this afternoon, who suggested it was an old hydrant or similar, as the plot we are in was next to a store and glass house/conservatory (part of the old manor the school now occupies). The pipe runs from their manor to us - and they were confident they could find a valve or stop-cock. We're meeting with them tomorrow to discuss more. Where I need some assistance is in who will have to foot the bill. We're happy to excavate a hole on the boundary line, and they have suggested they will cut and cap. The deeds we have from where the property was divided from their land date back to 1974, and has nothing on the hand drawn map regarding this line. There is a private water main, which is still used and marked, but that's nowhere near this one. Any advice on how to approach this? Yes obviously we're making the fuss and need to get rid of it. But it's their water line. I would assume it's probably us that may have to cough up, but just want to be sure. Thanks!

-

Week 1 - Finally clearing the site

AppleDown replied to AppleDown's topic in General Self Build & DIY Discussion

I think that’s what we’re thinking. Might use some of the brick/mortar supports from the old chalet stacked up when we place it down too. Will report back! -

So after three years of planning shenanigans, plenty of back and forth over designs and a house sale that is (hopefully) completing soon, we're finally doing something meaningful on the plot. Last week saw us mark the foundation outlines, set up a few levels and work out a plan of action for clearing the site. First up is removing the leftover brick supports and plastic sheeting from an old summer house/chalet, then on to the the overgrown brambles and finally clearing a tonne of dead wood from years of blown down trees that were cut up and left in place. But the biggest and most precarious job will come when we try to move the tree house my late grandfather built back in 1992. It's stood the test of time, providing many adventures for both myself and my brother, and now our two young boys. The fact that three tress around it that were felled in numerous storms over the past 30-years managed to just miss it is a bloody miracle. So it deserves all the care and attention to move it to a new safe spot, and receive some much needed replacement legs, boards and felt. No idea how we're going to do that though... Next week we hopefully start the dig out, ready for the piles - but the rest of this week will be clearing, laying some hardcore and marking out some of the drainage/utility runs. More to come!

-

We're going electric in the first floor ensuite. Easier to control - especially when the other half wants warm floor to wake up to!

- 18 replies

-

- 1

-

-

It's not cheap - the best product and buildup for the floor from Topcret is about £160m2 including install.

-

We visited a friend who microcement last year and we fell in love with it - so much so that we want a good 65m2 of it downstairs on the build. We've gone to a few different providers and each one uses a slightly different buildup. The two we've had the best experience with so far - and the ones with a more 'technical' approach - have been Forcrete and Topcret. There were a couple of local installers who quoted, but they simply just use a primer and then a couple of layers of product and a sealer. The two mentioned have a much more substantial process of building up the layers, adding strength etc. Yes it's all theory at the moment until we get it down - but from the time it takes to actually apply, the number of layers and the specific build up, I'm happy spending the extra £s on it vs tiles. We have also done our own 'scientific' stain testing with a few sample sheets on cement board. Went wild with the usual coffee, raspberries, spirulina and ketchup - baked in the sun and didn't leave a mark.