Tims

Members-

Posts

33 -

Joined

-

Last visited

Personal Information

-

Location

Leeds

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Tims's Achievements

Member (3/5)

3

Reputation

-

A neighbour tried to sell me some like that that his builder had left when he'd kicked him off his job. It was obviously ripped out of some where and then stored out in the elements for some time and had a similar date stamp. I pulled some out of a dry 15 year old conservatory floor that looked perfect, so I expect that the stuff shown has had a hard life and been out in the elements for some time.

-

Best way to cut semi-rigid ducting?

Tims replied to jayc89's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Another vote for a craft knife, quick, easy and clean (if you don't cut yourself instead of the pipe😅). As said above the ridges show you where to cut and it doesn't need to be mm accurate also if you slip and cut into a ridge a little it's double lined anyway. -

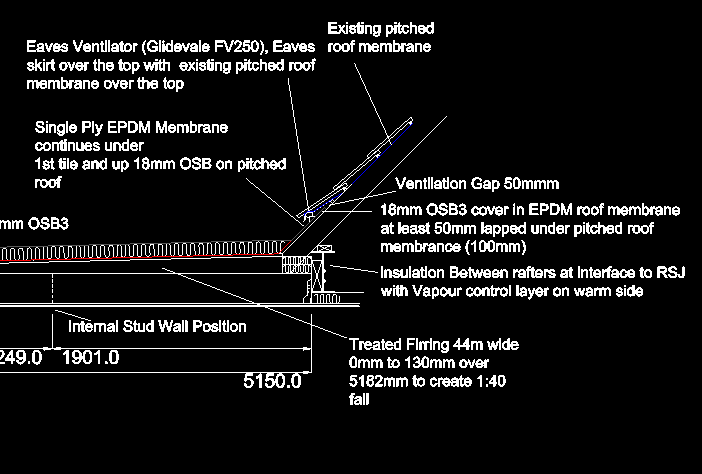

I've got a very similar detail though mine is probably worse as it's a junction between a warm flat roof and an existing cold roof loft space with an existing Steel perlin that the warm roof is tied into (dormer bungalow). I had big worries about the steel being a cold bridge and a condensation magnet especially as its above the family bath room. In the end I wrapped the warm side of the steal in a VCL and used silly expensive Primoclima Tesconvana tape to seal the VCL to the steel and around all of the joists the VCL for the warm roof also attaches to the steel and wraps up over the PIR of the warm roof which is cut to butt right up to the steel. On the loft side (loft has VCL at just above ceiling level) 400mm of rock wool fills sides of steel and I've got some going over it. As its an area of concern I've looked at the loft side on cold days and there are no signs of condensation (non on the warm side either). With a warm roof to warm roof it should be be much easier to continue insulation over or at least mostly up to your steel at both cold faces and keep a continuous unbroken VCL under and around the steel. It was a faff for sure on mine. If as your detail shows your steel/beam is fully on the side and under full depth insulation you can possibly juts your VCL over the top of it, though I imaging it has the pitched roof rafters on it.

-

My advice would be to definitely do it. Look on Kingspans website at their details to see what to do (you don't have to use kingspan but there details and calculators are usefull). Ideally you would do the room below too and extended the insulation and Vapour control layer right through the floor. Issues could be ventilation, and vapour control, you probably have trickle vents in your windows so this should cover the ventilation side for a quick job. Other things to think about are window reveals and new cills etc, you might also want to pop the windows out and fit cavity closers etc.

- 1 reply

-

- insulation

- old house

- (and 4 more)

-

What is the best duct to use?

Tims replied to Risemead's topic in Mechanical Ventilation with Heat Recovery (MVHR)

What are the 4 units? Is it a really big build or are they single room units. 75mm OD diameter semi rigid ducting is fairly usual for a radial system doubled up on a lot of feeds, 15 * 50m rolls I guess says its a really big build and again rigid galvanised spiral duct (insulated) is fairly standard to the outside world. I think that the only real reason that semi rigid is preferred over rigid PVC is ease of routing but if your system is being installed during the build I'm sure that rigid PVC is fine and may even have slightly less loss (maybe not though) -

I considered cement T&G tile backed boards for the bathroom floating floor but as we were getting the extension screeded I went for screeding this room at the same time (I'm glad that I made this decision). If you aren't tiling and don't bother with UFH there are details (I think kingspan and celotex have one) for chipboard floating floors on PIR (you need DPM and VCL) , there are also details out there for tiling floating floors with various cement boards over T&G floating floor chip board or just T&G cement board ( I don't know how good these are and where we haven't screeded I am just going to use laminate flooring). After researching lots of solutions I came to the conclusion that if you want UFH you are best going for a much thicker build up floor than you currently want.

-

We have 100mm PIR and 50mm perimeter insulation plus 40mm anhydrous screed with UFH it meets building regs, it works well and has a good U value, the heating goes on for about an hour in the morning and an hour in the evening and we keep the heat in the room (it is well insulated though). We also have one 1 renovated ground floor bathroom with 50mm PIR, UFH and floating screed (more relevant), the total build up is 90mm however, I ummed and arred about having UFH in here and only 50mm of PIR under it for quite a while before I took the risk. The later works and keeps its heat but we are probably loosing more to the old concrete slab than we would like, as its internal the perimeter loss isn't as bad as it will be in your case. Again the heating is on for about an hour in the morning and an hour at night and room stays at around 210C through out the day so something appears to be working. The rest of the renovation will have 50mm PiR under 18mm floating flooring (due to height with DPM and VCL too) and no UFH this still gives a 68mm build up. Without UFH, 30mm PIR and a floating floor will get you your 50mm and be better than nothing. don't forget that you will probably need to level your existing slab with levelling compound or sand before you put PIR down if it's anything like ours. PIR's nasty stuff but if you're short on space it has excellent thermal resistance when compared to some of the less nasty alternatives. I personally think that the 25mm or so EPS UFH panels on the market with routing for UFH pipes over an uninsulated concrete floor won't have the required U value for a good UFH system and will be pretty pants.

-

We have a similar build up to your architects proposal. Rendered Block 50mm clear gap 50mm PIR 100mm medium dense block 50mm PIR taped and sealed 38mm battens fixing PIR to walls, giving a service void and cross noggins placed for kitchen units and TV etc. 12.5mm palsterboard gives a U of 0.16 (not including the ventilated gap and outer block in U value calc) I've got no issues with hanging TV's etc as I thought about this u front. I considered using a 150mm cavity but it was easier to tie into the existing house and maintain the existing 50mm cavity (less faff). This approach also helped me with getting the new structure air tight. I also considered 100mm cavity with 90mm taped PIR but I didn't trust my bricklaying enough not to fill it with snots and leave paths for damp tracking though to the insulation, it would probably have been fine. Other down side of 90mm fill is regs at the time (now still?) call for a 50mm clear gap and I would have had to convince my BCO that my brick laying was up to par and that I have achieved the manufacturers specs exactly.

-

Should I go with an MVHR?

Tims replied to anonymous's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I'm coming accross air leaks that are basically due to the lazy sod that tinkered with the house before me and hopefully had some sleepless nights. I guess that an 1880s house is better sealed than a bodged 60's one. Hopefully I've found the worse of it😅🤦♂️ and the linked article makes me feel a liitle better about the process. -

Should I go with an MVHR?

Tims replied to anonymous's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Interesting, I'll be giving this a read, the introduction is promising. I am in the process of re insulating and fixing the air leaks on a 1960s home and was coming to the conclusion that MVHR was a bit of a white elephant and a waste of time in a house like mine. The new bits are well insulated and sealed the old bits are a nightmare of air leaks and every time I remove plasterboard to fix drafts I uncover new cans of worms. I hope that linked article shows that I'm not wasting my time too much. -

you can buy facia/sofit vents though they might stick out like a sore thumb if they are fitted to the front of the facia after the fact. I'd also be concerned that unless you pull your plaster board down and try to follow a cold roof detail with tight fitting insulation between the rafters and a ventilation gap above and probably some air sealing ( and vapour control wouldn't hurt) that you may make things worse and just introduce more drafts and cold through them. You also like you say don't want condensation on your timber.

-

I wouldn't be surprised for it to be unventilated if they haven't insulated it. If you can see into the flat roof from the roof void as long as you have your loft lights off I'd expect you to be able to see some daylight coming in from the fascia or soffit if it has vents.

-

Mixing brands for ducting

Tims replied to I N's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Should be fine, I have a mix of brands for semi rigid 75/63mm ducting, plenums and manifolds/distribution boxes and no issues