Digmixfill

Members-

Posts

186 -

Joined

-

Last visited

Personal Information

-

Location

Stone

Recent Profile Visitors

2885 profile views

Digmixfill's Achievements

Regular Member (4/5)

20

Reputation

-

Rafter spacing with internal dividing walls?

Digmixfill replied to Digmixfill's topic in Roofing, Tiling & Slating

Building control need the structural engineer's paperwork and they already provide approved rafter span tables. If I where creating some exotic roof style, then it would be prudent to involve them at an early stage, but this is a simple change that results in better roof insulation. Our BC inspectors have so far been really helpful and very accommodating, especially when making improvements. -

Rafter spacing with internal dividing walls?

Digmixfill replied to Digmixfill's topic in Roofing, Tiling & Slating

Everything has to comply with building control, so I don't think changing a purlin to a beam will make any difference to them as long as everything is done correctly. The external look of the roof will not change, so planners won't give hoot about it. -

Rafter spacing with internal dividing walls?

Digmixfill replied to Digmixfill's topic in Roofing, Tiling & Slating

I'm still undecided about the insulation between the rafters. It will be either PIR or mineral wool. I don't mind having to trim odd shapes and sizes. It will be a pain, but in the scheme of things a small job. Roof detail in the plans states "existing", and existing is rather rotted and worm ridden. Took the opportunity to change the roof to ridge beam and vault the lot. Rafter tables suggest we can use any spacing up to 600mm. -

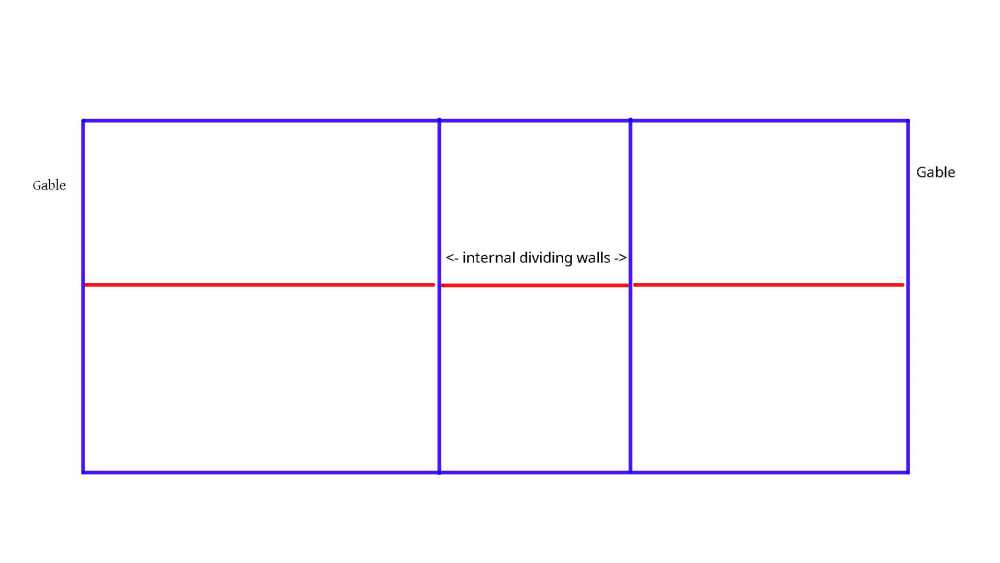

A rough layout of part of our roof is in the attached diagram. A gable at each end with internal dividing walls, with a separate ridge beam for each room. I'm aiming to place insulation between the rafters across the top of the dividing walls. There will be a service gap and counter battening with more insulation below, so rafter spacing doesn't have an effect on plasterboarding etc. I know that the end rafters need to be spaced from the gables with blocking and restraint straps, but i'm unsure what to do spacing wise around the dividing walls? Also, when starting fixing rafters is the best plan to place one at each gable and lay a string between those to get the best line? My plan is to start with an assumed 50mm birds mouth seat with the assumption that I can adjust in-out from 35mm minimum to 1/3 rafter depth maximum.

-

I tried searching for details of allowable overhangs, offset joints etc, but didn't find any wall plate rules other than minimum 38mm deep, must be lap jointed and the 3m/3 rafter span minimum length. If overhangs and offset joints are acceptable I'll experiment and pick the option that is the least offensive I'm going to be the chippie, I hope. The new inner walls are equal heights, but with the building itself not being fully square they aren't parallel. Only two birds mouth per rafter, but I won't be able to template and copy.

-

Hello everyone, I've been dry fitting wall plates and have one niggle to deal with. It's an artefact of my wonky walls When I built the new inner leaf it was stepped back from the existing walls to form the cavity. All of the other junctions are fine, but one junction across an internal wall has an offset of ~ 15mm. If I place the 75x100mm wall plate straight across here I get an overhang. What is the best way to deal with this?

-

Really? It would make my life much easier if I could use a small plate under the valley rafter alone and then step up to different level on the other side of the wall. The thing that steered me away from that is "Wall plates should be a minimum of 3m or extend over at least three joists". The valley rafter wall plate would fail all of those requirements. The small wall part might also fail those. I don't think I can get three common rafters on it at 600 spacing unless the first rafter is tight up against the wall.

-

It's not clear from the images I posted earlier, but the block wall in the picture is short. It provides a cavity to the outside wall up to perpendicular wall of the single story room on the other side. I would get two or three common rafters on the double stacked wall plate and the valley rafter on singe depth end of it in the room to the left. New common rafters would continue in the existing wall plate position to the right.

-

Ladies and gentlemen of the jury, New internal leaf stepping back from original walls is causing a height difference between the west and east wing of our L shaped building. Is it acceptable to stack timbers in wall plates? In the mocked up example I have a stunt valley rafter sat on a 75mm wall plate in the outer corner of our L shape. The wall plate is around 1.6m in length and passes through to the south wing, and has another piece of timber above it to take up the extra space beneath my stunt common rafter. Laser level is set to the masonry top on the west wing.

-

Vaulted roof insulation over dividing walls?

Digmixfill replied to Digmixfill's topic in Heat Insulation

This was part of my thinking. It worried me that I couldn't find a single instance of someone insulating over a masonry internal wall.