-

Posts

26430 -

Joined

-

Last visited

-

Days Won

360

Everything posted by Jeremy Harris

-

The "emergency use only" 50 litre Heatrae Sadia arrived today. Looks like it will be dead easy to install, as it's not heavy and will be an easy one-person lift up on to the wall above the services room door, especially as it has an easy to use "hook on" wall bracket. Yesterday an "eco" shower head arrived from Victoria Plumb. Pleasantly surprised by the performance of this, TBH. It's rated at only 7 litres/minute but subjectively it feels a lot better than that. My wife (highly critical of feeble showers) said she prefers it to the 10.5 litres/minute one we've been using for years. Be interesting to see the energy the SA uses tonight to recharge, after a couple of showers with the "eco" shower head. The last two nights it has taken near enough exactly the same time to charge, 1 hour 10 minutes, so about 3.3kWh*. If the shower water usage has been reduced by around 30%, I'd expect the recharge time to reduce. This small water heater holds water at its max temperature of 70°C (mixed down to about 50° for DHW and then mixed down again to ~38°C at the shower) to supply well over 80 litres, so more than enough for ten minutes of shower time with the new head. I'm planning to us it as out primary hot water system for a day or two once it's installed and commissioned, mostly as an experiment. Although such a low volume hot water system flies in the face of everything that is commonly stated as being essential for a reasonable level of convenience, I'm really keen to push the boundaries a bit and see just how little we could get away with, without too much inconvenience. Although the unit I have has a standard 3kW immersion, the Eddi has the option of being able to set a lower power limit. For those with battery systems this can be useful, as it can keep peak load within the inverter rating (ours is rated at 3.6kW max, in reality it manages a bit closer to 3.7kW). One advantage we have is that our hot water often tops up overnight, during the off-peak slot, so the water heater won't have lost much heat between its thermostat having turned it off and the first shower (usually around 07:00). This does mean the efficiency hit from storing hot water (which was the main reason for me opting for a SA back in 2016) won't be a major issue. * That 3.3kWh is actually significantly lower than the charge that went in to our old SA UniQ 9kWh unit over the past few months. I have no idea if this is in any way relevant to the failure, but, even though I don't have a lot of data they do seem to indicate that the new Thermino is using less energy. Nothing else has changed, it's plumbed to the same pipes and run from the same Eddi, with no changes to any settings, yet it seems clear there is a very slight reduction in energy use, perhaps around 10%.

-

It's really about having something to very quickly fall back on, Nick. Not being able to shower for the best part of a week was a real nuisance when the SA failed, so having something relatively affordable that can just be switched on to give us some hot water would be handy. TBH if the SA does ever fail again then it will get replaced with a slimline UVC, but that's a lot of work, as it means relocating the hot and cold water distribution manifolds, relocating the UV water treatment and filter, and probably relocating the 100 litre pressure vessel, in order to get enough space. It's doable, but probably two or three days work, on top of whatever delay there might be in getting someone in to do it. That latter problem is one of the main reasons for the backup. When I was ringing around the two people that were slightly interested made it clear they wouldn't be able to look at it for around 3 to 4 weeks. This little 50 litre water heater isn't going to be the answer long term, but it is something that can be fitted quickly, with very little disruption (might have to have the water off for half an hour, tops) and can just sit there ready to be turned on and give us a couple of short showers a day (I hope!) if the worst happens. It wouldn't interfere with the later installation of a slimline UVC in future, either, as it'll be high up on the wall above a door, so might be worth keeping if we did change to a UVC, if only to give us hot water if the immersion were to pop its clogs. I'll freely admit to being a bit keen on having backups, but our experience so far has shown they are a blessing. Our well pump failed about 5 years ago and having a backup pump, all wired and plumbed to a roll of MDPE, complete with a waterproof plug, was great. Took about half an hour to haul the old pump out, lower the new one in, make off one 25mm MDPE union and plug the mains in and we were back up and running. Needless to say there is now another spare pump hooked up and ready to go in the back of the garage! We even (by accident) have backup heating. The MVHR has an A2A heat pump, not very powerful, it draws about 400W, but when there was a power cut a couple of years ago it was great. We didn't have enough spare battery power to run the main ASHP, but there was enough to run the small one in the MVHR and it did a surprisingly good job at keeping the house warm.

-

Charles Austen ET100 air blower failed again........

Jeremy Harris replied to ProDave's topic in Waste & Sewerage

I built a remote box to house the air pump and alarm, because I wasn't wholly happy with having it sat in a box dangling over the main chamber of the unit (we have a BioPure). The main advantage of doing this was that, with the box being by the side of the drive I'm much more inclined to lift the lid and check the pump and alarm: -

Charles Austen ET100 air blower failed again........

Jeremy Harris replied to ProDave's topic in Waste & Sewerage

I don't know if our experience with blower pumps is typical or not, but we are still using our ten year old Secoh JDK pump with no failures so far. I ignored the servicing instructions (out of laziness) and just bought a spare pump plus a couple of sets of spare diaphragms, so if the pump failed I could just quickly swap in the spare and replace the diaphragms in the old one in slow time. I ran out of bottle after 7 years of non-stop operation and changed the diaphragms as I was sure they must be about to fail. It didn't need this at all, as the old ones looked just fine. The pump's been running for about three years on the new diaphragms and shows no sign of giving up. The only thing I do annually is take the top cover off and give the air filter a clean, as it tends to collect a lot of dust and dead bugs. Other than that it's just quietly got on with doing its job. -

I've ordered one of the 50L Heatrae Sadia horizontal water heaters, should be here at the end of the week. Nice that it comes complete with all the bits needed to install it, PRedV, accumulator, tundish, built-in T/PRV etc, although the PRedV is redundant, as I already have a 3 bar one on the supply, plus our well pump cannot exceed about 4.5 bar anyway, given the depth of our well. If anyone wants a 22mm PRedV they are welcome to it, as I already have one spare sat here. Plan is to fix a doubled up bit of 19mm marine ply to the wall above the door, secured with loads of hefty screws into the studs behind the plasterboard. Should be fine to then bolt the bracket to this, as the max weight when full is only a tad over 70kg. Nice thing about this water heater is that it isn't smart, something of a rarity now. Last thing I want for a standby, emergency hot water system, is something that is too damned clever for its own good. Quite why anyone would ever feel the need to have a WiFi connected and controlled hot water heater is beyond me. I just want something simple that will provide some hot water if things go awry. Last thing I need is to be faffing around with an app in order to just have a shower.

-

Thinking about it, it'd be easy to buy a lower flow shower head, perhaps a bit like the ones used for electric showers, to use if we had to resort to the backup hot water system. The shower head we use all the time has a flow rate of around 10.5 litres per minute (I only know this because an annoying building inspector wanted me to measure it, then insisted a flow reducer be fitted - removed as soon as the house was signed off . . . ). I could probably find one with a much lower flow rate, rather than fit a flow reducer, simply because the flow reducer really reduced the force from the jets. If I fitted, say, a head with an 8 litre/minute flow rate then we'd get close to 10 minutes of shower time, which is pretty close to normal daily use anyway. This means that a 50 litre heater may well be all we need. These Heatrae Sadia units look well enough made, stainless steel tank and immersion element, just a simple thermostat for control and all the connections at one end.

-

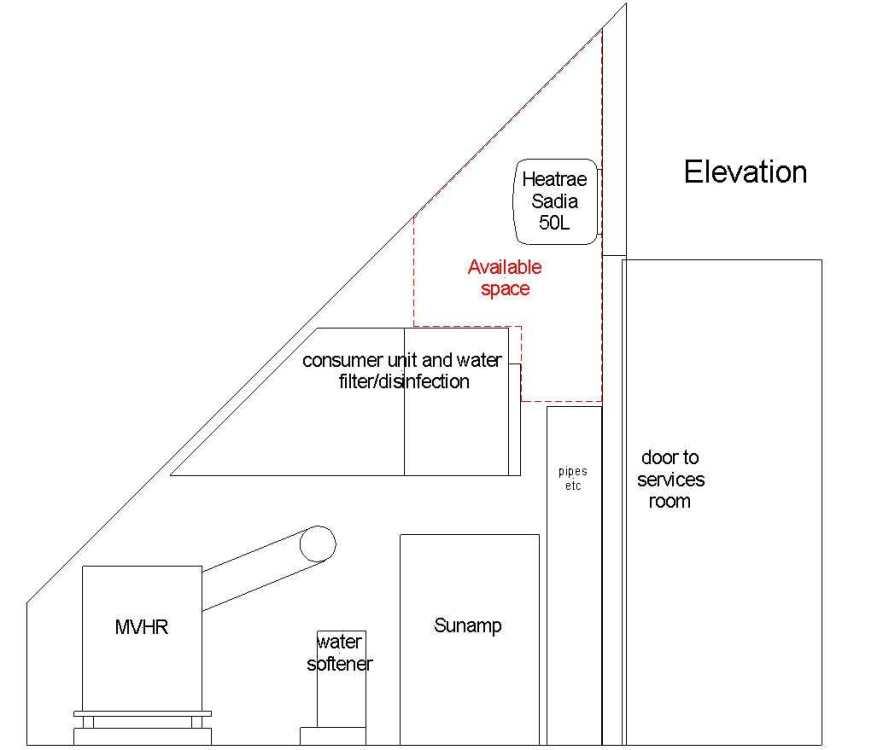

I can't make up my mind what to get to provide us with an emergency back up hot water supply. Space is really tight in the only area I could fit something. Below are rough scale sketches of the elevation and plan view of this area, with the only spare space marked in red. The best bet seems to be to find a horizontal water heater that I can wall mount, above the door. There is "just" room to get up to a 500mm diameter unit up there, no longer than 1200mm, and it must have all the connections at the end nearest the end wall (top in the plan view). The pipe work for the Sunamp is directly below that end, so plumbing will be straightforward, plus I can run a drain from the tundish out through the wall to near-ground level, as there is just gravel in that area outside. There's room for the expansion vessel in the corner where the pipes would come down, too. The unit that seems to best fit the bill is one of the Heatrae Sadlia Hotflo multipoints. The 50 litre would be a lot easier to fit, as it is slimmer and lighter than the 80 litre (sticks out 371mm from the wall versus 454mm) Both would be OK within the 1200mm max length restriction. The fitting bracket these use looks ideal, too, as you just bolt it to the wall and then lift the unit up and hook it into place. The question is whether 50 litres of hot water is OK as an emergency supply. My feeling is that it would do at a pinch, as the sums show that it could deliver at least 70 litres of shower temperature water, so enough for about 7 minutes of shower time. The full re-heat time is a bit over 40 minutes, so just spacing our two morning showers out a bit more would allow a couple of reasonable showers. The temptation is to get a larger unit, just in case, but I have to keep telling myself that this is just a standby system, to give us a backup source of hot water for emergencies, not our primary source of hot water. I've sketched in the smaller of the two Heatrae Sadia heaters below, and it looks like it would be a reasonable fit. I've not been able to find anything comparable, in terms of diameter, everything else just looks a bit too large.

-

The stair climber model that the Zonzini crew used here would cope with anything you could get a sack truck up, I think. It would probably be OK with gentle turns in a staircase but I doubt it would work on a tight spiral staircase. There are a few videos around on YouTube showing these things in action, they might give you a better clue as to whether or not one would work on your staircase: https://www.youtube.com/@ZonziniSrl/videos Our local hire place has them, but they are costly to hire, when I looked it was around £230/day, including delivery and collection. Worth it, given there is no alternative, but I was seriously looking at just buying a secondhand one. Might be a useful thing to have, or I could probably sell it on for about the same as I paid for it. They are around £800 to £900 to buy secondhand.

-

I lifted our original unit upstairs, on my own, with a sack trolley, loads of spare climbing ropes, two Petzl stops as safety brakes, a steel cable and a tirfor winch. Took me about half a day to get it up a single, straight, flight of stairs. I used the tirfor with a 2:1 tackle to move it up one step, then locked it off with the ropes and Petzl stops, re-jigged the steel wire and tirfor so I had enough movement to get it up another step. The sack truck was rated to carry 150kg, but really struggled and has never been the same since. They only way to move these things safely is with something like the guys used on Thursday, a Zonzini powered lift and stair climber. That had the advantage of being like a mini-fork lift, in that the forks can be motored up from floor level to around the level of the back of a van, and then a couple of people can just about slide the unit across and strap it to the Zonzini. They are, without a shadow of doubt, a manual handling nightmare if you're on your own.

-

The other slimline twin tank unit I've found is this one: https://www.modernheat.co.uk/product/tesy-bellislimo-80-intelligent-electric-hot-water/

-

They have changed a lot, @TerryE. Ours has the two pipes and two cables going in near the top of one side. There is no need to access the other three sides. There are no removable side panels any more, the case just has a removable lid, under which are the electrical and pipe connections. You only need access to the top and the upper part of one of the three sides that can be used to bring the pipes and cables out now. The pipes need enough space on the side chosen to connect them to allow an elbow to be fitted to take the pipes, so perhaps a 100mm wide gap at that side. The pipes and cables can can come out near the top on either of the long sides or one of the short sides, and no tools are needed to change this orientation internally.

-

I will ask, I need to call him as soon as I'm ready to get the standby water heater sorted.

-

I'm sure I could have called them back, but the guy drove down here from Nuneaton and frankly there is no way I could live with asking someone to do a 5 or 6 hour round trip for a ten minute fix I could do myself. As you say, I'm sure it was just one of those things, there was not the slightest indication of poor workmanship that I could see. The really massive PITA with these things is that they just cannot be quickly sorted if they do weep. A few seconds nipping up a slight weep on a compression fitting is a quick and easy fix. Battling to cut off and replace one of these press fit fitting is both a pain and time consuming, as well as carrying the risk of damage to the pipe. If they were easier to get off and replace then maybe they might be OK, but as they stand I'm not going to give them houseroom in future.

-

It's now replaced with a compression fitting (can't use a soldered one as it's too close to the Sunamp). TBH I struggle to see any benefit from these crimp on fittings, other than speed of assembly. They seem to have the same downsides as pushfit, in that they rely on an O ring to seal, with the added issue that the crimp bit can distort the O ring sealing area (which is I think what happened here). They are a PITA to get off, too. I had to use a pipe slice around the crimped part to get that off, then gently use snips to peel off the bit with the O ring (as I didn't want to make the pipe any shorter). Luckily the slightly dinged end of the pipe is well away from the olive in the new fitting, so no risk of that not sealing, but it wouldn't be possible to get one of these off like this and re-use the pipe with a Yorkshire or end fed, due to the dings. In applications like this, where you can't use heat and need a bit of adjustment so there's no stress on the pipes it seems to me to be hard to beat an old fashioned compression fitting. They are pretty forgiving and best of all can be disassembled quickly and re-used. Not sure if there is much of a price difference, either.

-

Many thanks! That just goes to show how easy it is to be mislead by stuff on the internet! I suppose the reason people are promoting these things so heavily is because they are quick and easy to use, then, so they save a lot of time on a job. That figures, but it is depressing, all the same. I'd like to think that people who promote stuff like this are honest, but I guess honesty is just another commodity to be bought and sold. . .

-

One slight problem has appeared (only spotted when @SteamyTea called around earlier - thanks, now fixed!) in that a crimped on type elbow (the ones that need the expensive machine to fit) developed a very slow weep. It was dripping at a rate of about one drip every ten to fifteen minutes. Struck me as being odd, as everything I've read/watched on YouTube about these crimped fittings has been very positive. I really did not expect to find one with a slight leak. Anyway, ten minute job to fix, as I had some spare 22mm pipe and a couple of compression elbows, so all is sorted now. This wasn't Sunamp's fault in any way, my guess is that it was just one of those things. I cut away the neoprene (whilst Steamy Tea was here) and I can't see anything wrong with the crimped fitting (that may be the wrong term, but hey ho, I'm not a plumber!). Any views on this type of fitting, @Nickfromwales? Am I mistaken in thinking they are normally very reliable? I know that it's far too easy to get mislead by social media stuff, especially YouTube, but I've not seen anything negative about these fittings, TBH, so suspect we've just been unlucky. Whilst I had the water off I've added a tee and two 22m ball valves, one on the Sunamp output, the other off the tee, with a stop end for now. The plan is to fit the small wall mounted UVC some time in the next few weeks, as a backup source of hot water. If we need to switch over hot water sources then it's just a matter of closing the Sunamp valve, opening the alternative source valve and switching a rotary changeover switch from the Sunamp to the back up. If we never need to use it that will be great, but it will give us peace of mind that we have an alternative that we can very quickly switch over too if we really need to. What's even better about this is that with just a 2kW immersion the backup can be fully heated in under two hours from the battery system, as we pretty much always have at least 7 or 8kWh of spare energy available even on a dull day. The price looks very reasonable, too, even including the labour cost from the local plumber (who's becoming my new best mate, he really deserves to get on with his positive approach - like a breath of fresh air given my recent experience with a rip-off merchant). Hope you got home OK after your marathon trip today, @SteamyTea. Makes me glad that we no longer live down in your neck of the woods, with that long haul just to get out of the county.

-

Absolutely! Made in Austria by Magna Steyr and it showed in every single detail. The build quality was absolutely superb, markedly better than the Mercedes I have now. It was a complex car though, both the electrical stuff and things like the air suspension and other electric widgets, so after owning it for three and a bit years and paying for the extended warranty, I kept worrying it would have some major failure not covered by the warranty, so sold it. The cost of EV repairs can be eye-wateringly high, so running one outside the warranty period carries a potential write-off risk on the basis of cost if something serious fails.

-

It was a December 2020 Jaguar I-Pace HSE. Far from being an efficient EV, but reasonable performance from 400hp and AWD, if not quite up there with the Model 3 LR AWD. Very comfortable and extremely reliable, as well as seeming to be completely free from software bugs (something of a rarity in modern cars!). I replaced the I-Pace in June last year with a Mercedes EQA Premium +. Smaller than the I-Pace and better suited to the roads around here, and a lot lower performance. It is pretty efficient though, massively more so than the I-Pace. My only minor gripe is that the software isn't as intuitive as it could be, although it announced it was updating just as I got home last night, so I've not yet had time to experience whatever may have been changed.

-

This approach of releasing immature products to the market and allowing the early adopters to test them is now the norm with some cars, too, it seems. I made the massive mistake of buying a new Tesla Model 3 in 2019, when it was first available here. That car had so many manufacturing defects, mostly down to process control (or the absence of) and poor software that clearly hadn't been fully tested, that it had to get taken back to the nearest Tesla service centre 6 times during my first few months of ownership. Given that this was a ~150 mile round trip each time I ended up sick and tired of the thing, so sold it after 14 months (and I'd never buy another one). Its replacement was a car that had been in production for three years, and it showed. Zero defects or issues in three years of ownership. The moral of this story is to never, ever, buy a brand new product. It's not a new thing, either. There's an old saying in aviation "Never fly the Mk 1 of anything". It does seem that technology companies, in particular, are far too willing to inconvenience early adopters, though.

-

I'm doing this with the replacement, it's mentioned a bit further up the thread. One problem is that these units are very heavy, our old unit weighed 155kg, the new one is slightly heavier I believe. This means it would be very difficult to lift one over a lip, so I'm just making the edge boards watertight by sealing them with sikaflex to the base board, after the unit has been slid into place.

-

If the container(s) were cylindrical, rather than rectangular, I suspect many of the structural issues (if indeed these are key) might just go away. One of the slimline wall mounted UVCs I've been looking at is slimline because internally it has two smaller diameter cylinders mounted side by side inside a rectangular case, with the gaps between the two filled with foam. Part of the efficiency of the Sunamp comes from the vacuum insulated panels, which have to be flat I believe, but they could still be used with a two, or three, cylinder design within a rectangular case, with the internal gaps filled with foam. The size of the units would increase a bit, but not by that much. I've been doing a comparison of the wall-mounted UVC options and the slimline two cylinder ones are only a wee bit taller than the cylindrical ones for the same volume, but are about half the thickness/diameter. Depends how critical dimensions are when marketing these things. I'm looking at them as someone with a tight width and thickness limit and a not so tight height limit, others might view things differently. Most of the Sunamp installation photos I've seen online don't seem to be in particularly space sensitive locations. If I had to guess I'd say that height may well be the most critical dimension for many, so it may even be that a cylindrical unit that's about the same diameter as the length of the existing units (they are all the same length and width, they vary in height) might be acceptable.

-

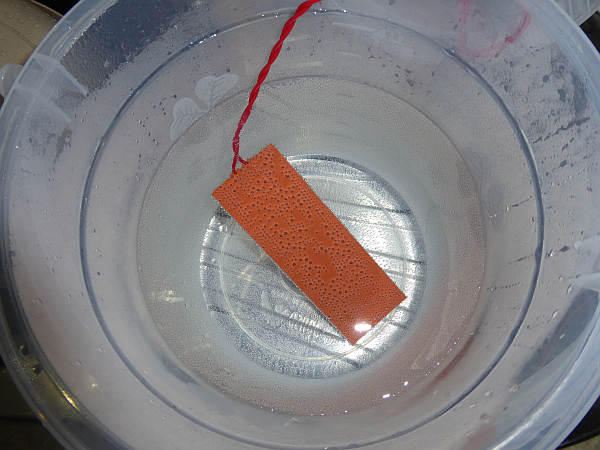

Funnily enough I ordered one of those USB rechargeable camping showers 2 days ago! To get warm water for a shower I put together a Heath Robinson arrangement using stuff I had around, two spare 20W, 12V silicone rubber heating mats (I had to buy four when I only needed one for a bag warmer), a 6A, 12V power supply and a couple of 5 litre lidded buckets. This worked very well, the heaters were plonked into each bucket and left on all night. By the morning we had two buckets of water at around 38°C, which was fine for a sort of cup-over-head type shower. we could have filled them from the boiling water tap, as the boiler for that holds 20 litres, but that would have meant carrying the buckets upstairs, which seemed like too much effort first thing in the morning! The bucket warming experiment, before I set them up properly upstairs:

-

I can post you a small lump if you want, Damon, might be a bit crumbly as the one big lump is that bit I've promised @SteamyTea. Not sure if I've still got your address, though, perhaps you can PM me if you'd like a bit to threaten your Thermino with, to make sure it keeps behaving itself. . .

-

Worth noting that although sodium acetate is chemically a salt, it's not very reactive, in fact it's used as a neutralising buffer for sulphuric acid to stop it being corrosive. The reason table/road salt is so reactive is because it's a chloride I think. Halogens want to react with anything and everything, hence the reason that swimming pools are evil environments for anything that might possibly corrode. Chlorine will attack a very wide range of materials, even at very low concentrations. I made the mistake of leaving a 5 litre container of hypochlorite path cleaner in the shed. The lid was on tightly and the container was in a plastic bag, with a cable tie around the neck, as it had been shipped, It wasn't leaking but the miniscule amount of chlorine that escaped was enough to surface rust everything in the shed within a couple of weeks.

-

We've got a couple of things on tomorrow, but if you know roughly when you might be around I'm sure I can be in. Not sure how big a lump you would like, this is the largest of the bits I've kept: