-

Posts

176 -

Joined

-

Last visited

Everything posted by Bemak

-

I don't think it will ever be airtight enough for it. I'm happy with a simple system like what John was recommending. Whatever works!

-

super - thanks for that. Those Greenwood fans look ideal. any recommendations for humidity activated passive vents?

-

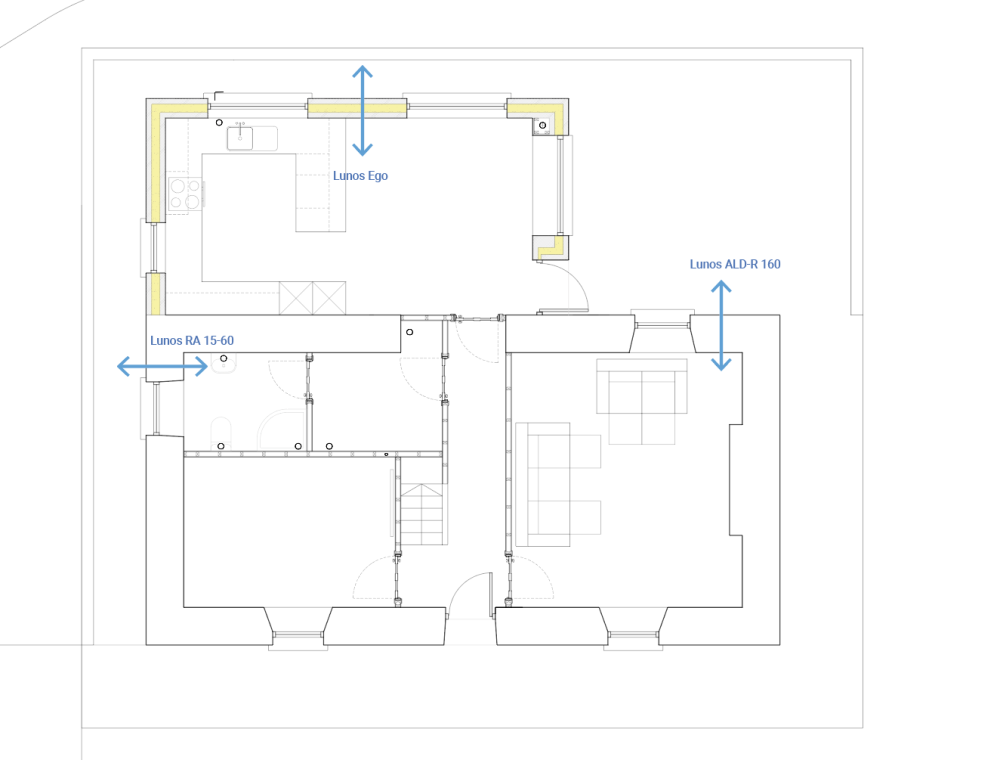

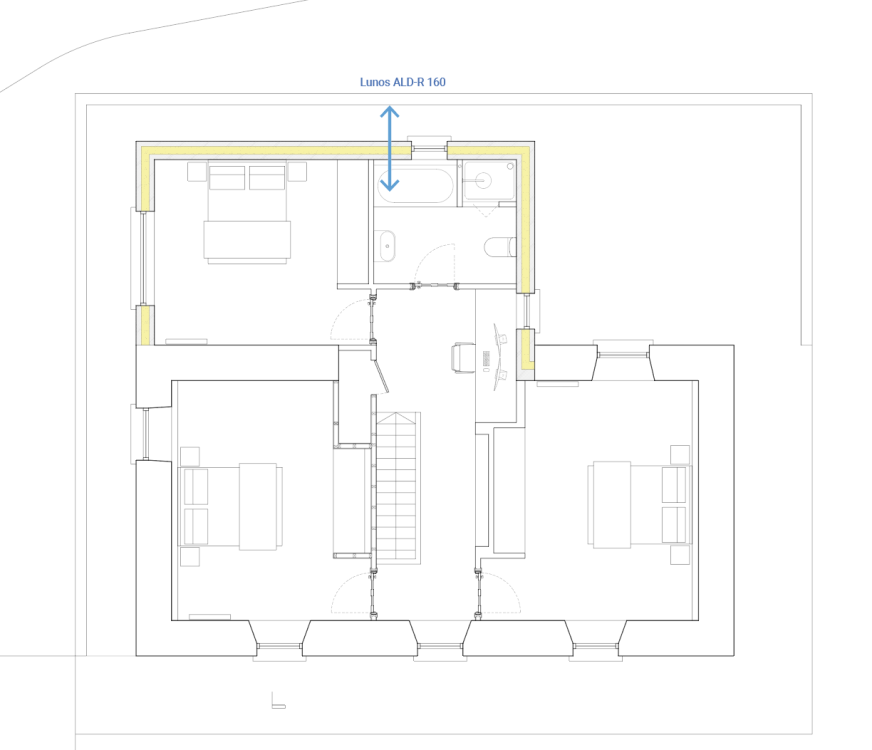

Looking to bottom out the ventilation strategy for a farmhouse I'm renovating at the moment. Had originally thought I'd go for a MEV system but I've since started to lean towards a dMEV system instead. The house is gutted at the moment so I'm thinking it would be a good time to start coring vents in the stone walls and get the mess over and done with. At the moment this is my thinking (based on the Lunos system. doesn't have to be Lunos). Note all windows will have trickle vents.: GROUND FLOOR passive vent in sitting room for stove extract wall vent in WC - which would also help vent the small utility adjacent (washing machine only, no dryer) another vent in the kitchen dining - the Ego is a new exhaust fan with heat recovery from Lunos kitchen will also have a separate extractor over hob. just not shown below. FIRST FLOOR extract vent in bathroom (Lunos ALD-R or Silvento). while all windows will have trickle vents, my feeling is I probably need another passive vent in the landing to balance pressure? I could core a vent in the wall at the bottom, to the left of the window but I would rather not have a vent here on the elevation. Could I provide a passive vent serving the landing via the attic/slate vent instead? if I need one? I originally had planned to duct a MEV system all around the house but I'm leaning towards the above because it seems a lot more straightforward? Appreciate any thoughts and advice.

-

replacing existing floor with new slab - minimum excavation

Bemak replied to Bemak's topic in Floor Structures

i think it will work out fine, particularly when we introduce a french drain. -

replacing existing floor with new slab - minimum excavation

Bemak replied to Bemak's topic in Floor Structures

-

replacing existing floor with new slab - minimum excavation

Bemak replied to Bemak's topic in Floor Structures

sorry - i never got a notification on this post. In the end we dug down about 500mm and put in 100mm compacted hardcore, blinding, radon barrier, and then a 150mm subfloor. Once the extension is built, the next stage is 150mm insulation, 70mm screed with UFH and then the floor finishes. I’ll post some pics now of the progress -

Ah - a buffer tank is what I understand that as. Sorry I was getting a bit mixed up. Yes we'll have a buffer tank in the system to stop the boiler from cycling. It will be a pressurised system with a cold water storage in attic, hot water cylinder in a first floor HP. I don't have a layout yet as I'm trying to decide on the system upstairs. I'm going to locate a manifold downstairs which will take the feed from the boiler and stove. It will link in with another manifold upstairs which will distribute to HWT and rads/UFH. The house is only 140sqm so it should be a fairly neat setup.

-

The boiler will be linked to a manifold under the stairs and from there it will run to the various areas/tank. I will have a back boiler from the stove feeding the system also. I'm not sure if that means I would be pulling water from thermal store? That's a good point though - if the bedrooms are ticking over anyway then the reaction time is less critical. New insulated slab going in downstairs with UFH hence why i thought I might just put it everywhere.

-

sorry - should have mentioned that. It will be an oil boiler

-

I'm in the middle of a refurb and I'm trying to decide whether I go for rads or UFH for the first floor bedrooms. My preference is for UFH to avoid hanging rads but my plumber thinks that rads would be better as they'll heat the space quicker. I don't disagree, particularly as I would be proposing to have the UFH pipework in pregrooved PLY under an engineered timber floor. I appreciate that the reaction time would be slower as the timber floor above the pipework would act as an insulator - but I'm not sure if that would be a major problem as we would typically only have the bedrooms at 19 degrees anyway. Just wondering if anyone has UFH in a similar scenario and how its working out? If you had the chance to redo it, would you go for rads instead?

-

I hacked a bit of render off a few years ago to see how labour intensive it would be. Found 3 layers of render had been added over time and it was very difficult to remove, often pulling stone with it. So I repaired the patch I removed. The intention is to render the house completely in the end. I had originally looked at dry lining internally but we've opted to go for 40mm of insulating lime render instead. I was told that over insulating internally could be a bad thing as the walls would sweat behind the gutex board.

-

Thanks John. That's interesting. Hoping to achieve that level of airtightness. I guess once the envelope is sealed we could carry out a test to see where it's at before deciding on MVHR. As you say, I'd probably be happy with a MEV setup. dMEV isn't really an option as I don't want to go coring 600mm thick rubble stone walls. I'm reroofing the house so I'll be able to add vents to the roof for a MEV system

-

yes we're putting in a new insulated GF slab which should make a big difference. the external walls are sand and cement render unfortunately. we looked into the possibility to taking it all off and replacing it with lime but it's a non-runner because of a) the prohibitive cost and b) as we're in an exposed area in the west of Ireland, lime render doesn't particularly suit the driving rain that we can experience for weeks on end. so the only direction for the walls to breathe will be inwards. we've stripped off the internal render however and thankfully the walls are quite dry as is. I'll install a french drain around the perimeter of the the house as well which should help with moving ground water away from the base of the walls. it's all we can do really

-

As posted elsewhere, I have started renovation works to an old stone farmhouse (150sqm) which involves the addition of a two-storey extension. We've decided to go down the route of UFH on both floors which will be run with a traditional oil boiler for now. We've allowed provisions for a HP in the future. The heating will be supplemented by a back boiler in a solid fuel stove. As the existing stone walls will be rendered internally with an insulating lime render to allow moisture to escape - I want to install a good ventilation system that will help to extract moisture from the house. The preference is for the unit to go in a warm attic, from which I can duct all the rooms. As the layout of the house is quite simple, the routes are relatively straightforward. In researching MVHR units, I stumbled upon Nilans Compact P2 unit which combines the ventilation system with the HW Tank which has it's own heat pump to generate hot water. On paper it sounds like a nice system - but it might be overkill for my situation. I suspect installing separate systems would be more cost effective. I would be curious to hear peoples thoughts on it, particularly if you installed a MVHR unit in a similar refurb scenario. At this point I wouldn't know which manufacturers would be considered 'premium' and which would be 'budget' so even to get recommendations in that regard would be great.

-

In the middle of refurbishing an old farmhouse at the moment and am currently working out service routes before the new slab goes in. I'm proposing to locate an external boiler about 20m from the house - the pipework will be 26mm pex pipe (10mm insulation) which will be run inside a 110mm Wavin pipe - all of which will be buried about 600mm below ground level. I appreciate that some element of heat loss will occur along the way - but as we're proposing UFH in the house, the reduced temperature shouldn't affect things too much. Before I lock this in, just wondering if anyone else has done something similar and if so, how has it worked out? Thanks! *update - apologies, I just realized that I posted about this already. Please ignore!*

-

thanks for the link!

-

As posted elsewhere, I've embarked on the refurb of an old 2-storey farmhouse. As part of the refurb I'm going to install a MVHR system to ensure that moisture and condensation is adequately dealt with. I'm also installing a new insulated floor slab with a radon barrier and sump. I was going to run the vent from the sump out under the slab and bring it up in a nearby flowerbed to conceal it. The idea is that I would just put a cowl on it and let it vent naturally. However, in a lot of instances locally, the radon vent is brought up to the perimeter footpath and just capped - then, if necessary, the cap can be removed and a duct with a fan can be installed to vent the sump. My issue with that approach is that I don't want the potential to have a vent running up the side of the house when we've been so careful to conceal all the services to date. However, as we are going to be installing a MVHR unit anyway, I assume it's highly likely that we'll never need to vent the radon sump in the future considering the house will be so well ventilated? The reason I ask is I may just revert back to the standard solution of capping it on the footpath as opposed to bringing it up in a flowerbed as currently planned.

-

thanks for all the replies on this. I've been distracted with demo starting on site. finally! what are peoples thoughts on UFH for upstairs as well?

-

thanks for this!

-

I recently came across 'over floor' heating systems which are essentially an underfloor heating system in a 30mm screed - the idea being that the system is much closer to the surface of the floor allowing for quicker response times while generally running at lower temperatures. I spoke to a supplier about it and they said the following which I thought was interesting "the system achieves a typical operating energy reduction of 50% daily compared to heating the same space using Under Floor Heating". "Conservation of energy on a daily basis sets the ground work for affordable heating and sustaining the building, the most significant feature of Over Floor Heating systems is the remarkable increase in comfort created by operating the system using water at body temperature". All sounds great. I'd be curious to hear of peoples experiences using such a system as I wouldn't be opposed to trying it on a refurb I've started.

-

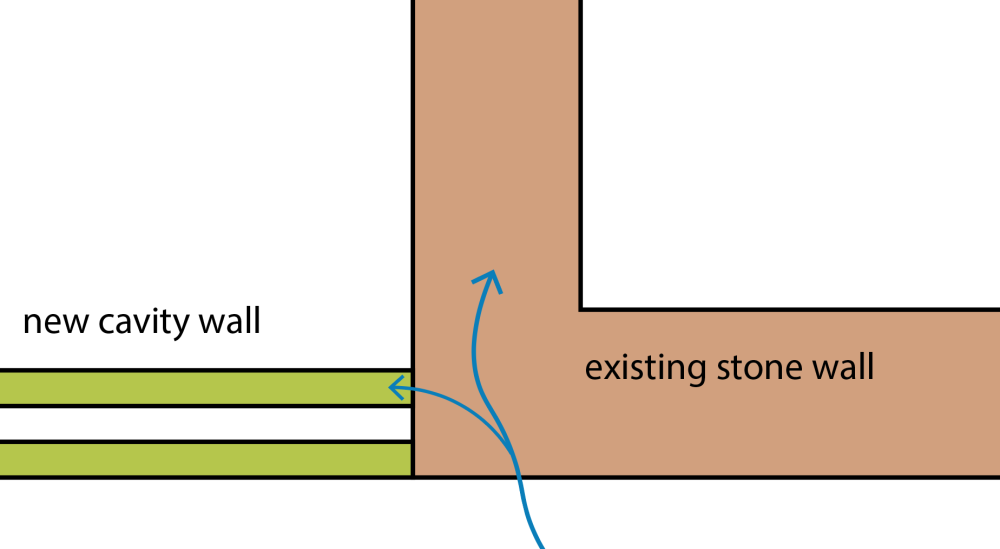

just a quick query on a detail I want to ensure is correct. i'm planning to construct a cavity wall extension to the side of an existing two-storey farmhouse. the new extension will replace an old stone extension and we've yet to determine if the stone extension was keyed into the stone of the main house. In any case - I was wondering how best to detail the junction between the new blockwork and existing stonework to prevent any water in the stone wall from getting into the inner leaf (as per the crude diagram below). Is a vertical DPC the best bet or is there a better way of doing it?