Wet weather, BC, SE, Drawings, cost and more wet weather

Our tale of delays and woe is competing even with @pocster for time taken

From Oct - Dec progress has one again been delayed by weather, flooding, cold and in all honesty a bit of incompetence on our part meaning we are further back than when we started.

This period started well enough with the trenches for foundation filled ready to start building walls.

After digging down and down to the required depth (or so we thought) we started to place the cellcore ready for the mesh / concrete.

Most of this had to be done by hand as we somehow managed to build the walls before digging deep enough for the hardcore and blinding and couldn't reach lots of it with the digger.

The cellcore and mesh were laid

Then this hit - storm babett

our road and the site were totally flooded and the work from the previous day ruined

After waiting for it all to dry enough BC came out and said wrong, wrong, wrong.

We had mis-read our plans and somehow forgotten to suspend our suspended floor and to add even more woe we hadn't left enough bearing space on the foundations for the mesh to sit on.

Cue 4 weeks of SE, BC and the associated costs. To be fair they were both really helpful at trying to sort out what was our mess with the least upheaval to us.

Then partially fill the hand dug hole, thankfully only one room not the whole house and having crushed 104 tons of concrete hardcore isn't in short supply.

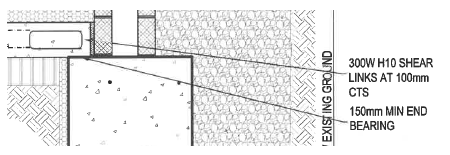

In the end we had to knock down what we'd built and get agreement from SE & BC that we could use Shear Links between the mesh sheets and have any overhang of 150 instead of 200.

I hadn't even heard of Shear Links so sourcing them was fun as neither had any of the main BM's.

there are also many different shapes, we needed shape 33, like a paperclip

So, amended drawings, shear links, time and everything else leads, once again, to more cost and more time.

It's also rained so much in the last few months that any progress was hampered.

We are still not back to where we were, the blinding needs whacking again so the cellcore can be put down again, the mesh needs placing again with the shear links, the walls need rebuilding to DPM and BC needs to inspect.

Then we will be back to where we were 2 months ago.

One day, I'm hoping to do a blog entry where everything is wonderful 🙂

More in a couple of months.

-

2

2

-

1

1

8 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now