Search the Community

Showing results for tags 'stud lining'.

-

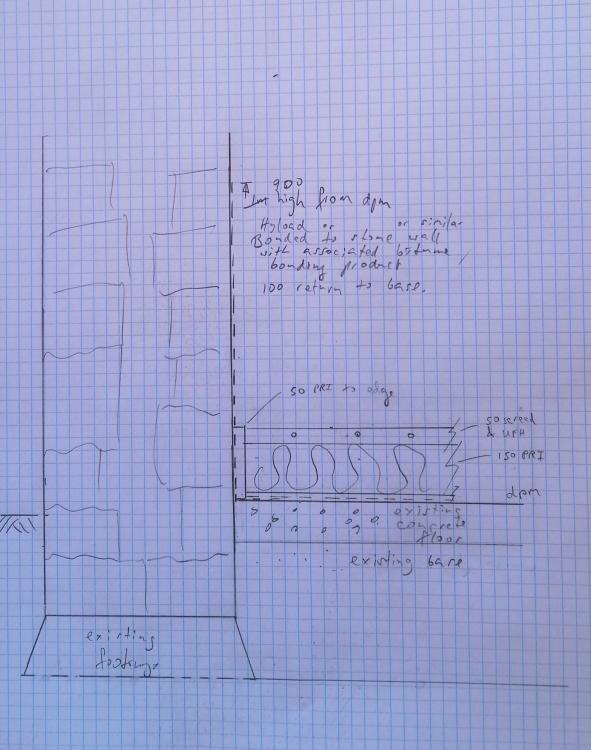

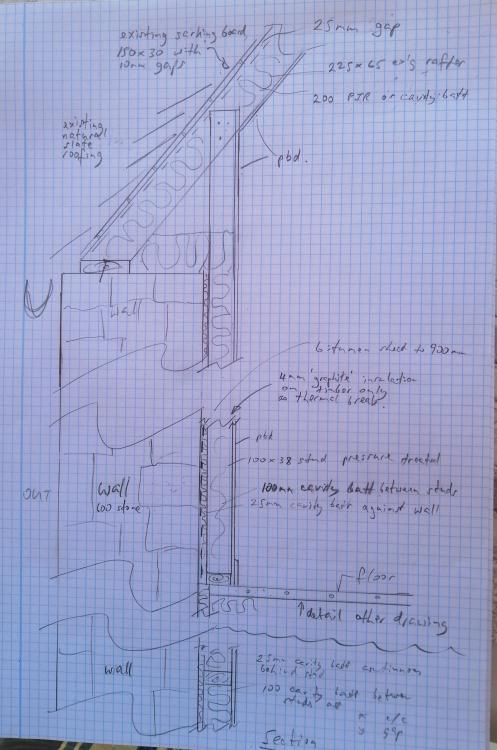

Would anyone care to crit this preliminary design please? 2 drawings below. Of course these will be submitted in cad form. The building is a Scottish farm steading. The walls and roof are substantially intact, and there is a concrete floor. The building regulations requirement is for 'reasonable effort' to be made re insulation, and that includes cost. As there is only 4.5m wall to wall, the wall lining has to be kept skinny. There is also a headroom issue in some locations, but I may increase the floor insulation where feasible, if steps can be avoided. Of course we want good insulation too, and I have come up with this compromise. The 1m of bitumen sheet lining shown at the bottom of the wall is cribbed from another steading's blog, and seems clever, but I don't know if it is expected or standard. The dpm may have to be radon spec. It is marginal and I will check. All existing timber will be sprayed. I am quite pleased with my idea of having a 25mm cavity batt between stone and stud, as it will provide a thermal break and also allow tolerance in verticality. As it is waterproof, I don't think we need vapour barrier. Which then makes me think, do we need that bitumen tanking barrier: it is there to keep the wettest part of the wall away from the inner materials, but the insulation can do that, as in any cavity wall. At £15/m this comes to a lot of money but may be worth it for peace of mind. I have shown a 25mm air gap between sarking and insulation, because it is required with PIR. Not quite sure why PIR needs it but Batts don't. Actually more is stated but it is guidance only, and we have sarking boards with gaps, which is much better for ventilation than whole OSB sheets would be. However, I think there will be much less waste in cutting PIR between the rafters, than batts. Adding a 4mm insulating strip to timbers before boarding is just a thought. I will calculate the effect on the U value and suspect it is trivial. theoretically it also provides a gap between insulation and board, and hence a surface, but i think that would be nonsense to allow unless cynically chasing a specific U value target. Cost-wise, I have to assume that availability and prices will settle down by the time of doing the work. What else might you want to know? Underfloor wet heating, air source. Mostly single storey with highish ceilings. Some existing upper floor, with very tight headroom below ties. Most of the roof soffit will be boarded over, perhaps exposing some ties. It is mostly in good condition but not pretty. Obviously we don't want to take off the roof and rebuild, so working underneath is the only option. All comments are welcome as are ideas, especially proven, but also wild, and do ask if anything is unclear.

- 2 replies

-

- insulation

- stud lining

-

(and 1 more)

Tagged with: