Search the Community

Showing results for tags 'steels'.

-

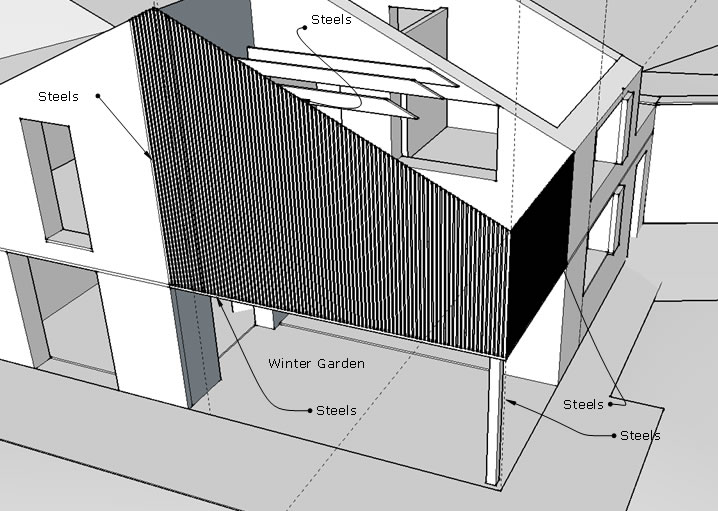

@MrsRA loves gardening. And that's why we chose a design which incorporated a Winter Garden inside the house. It is an unheated area on south west corner. The Winter Garden extends from floor level to the roof and so it needs steels to hold it in place. Those steels need to be insulated. A quick look at how we could get that insulation done threw up many types of insulation, and many methods of incorporating the insulation on the steel I bet someone here has done this before, and can offer advice. Please! Ian

-

Our Winter Garden - outside the heated envelope of the house - is a steel-framed construction. It will be open to the elements, and intended as a filter for the light from the south: all the rooms open into it or have a window onto it (except two). Debbie's keen on gardening. Me? Hmmm. Lots of people have been round to poke and stare at the build, among them a couple of local builders..... Talking about the Winter Garden, I mention we have been told that the steel frame for the garden needs to be built by a CE marked and Certified company. Cue snorts of derision, sucking of teeth and pithy Lancastrian. Who's correct? The builders or the ones with PII (Professional Indemnity) cover? WinterGardenIllustration.pdf

- 29 replies

-

- steel fabrication

- steel

-

(and 3 more)

Tagged with:

-

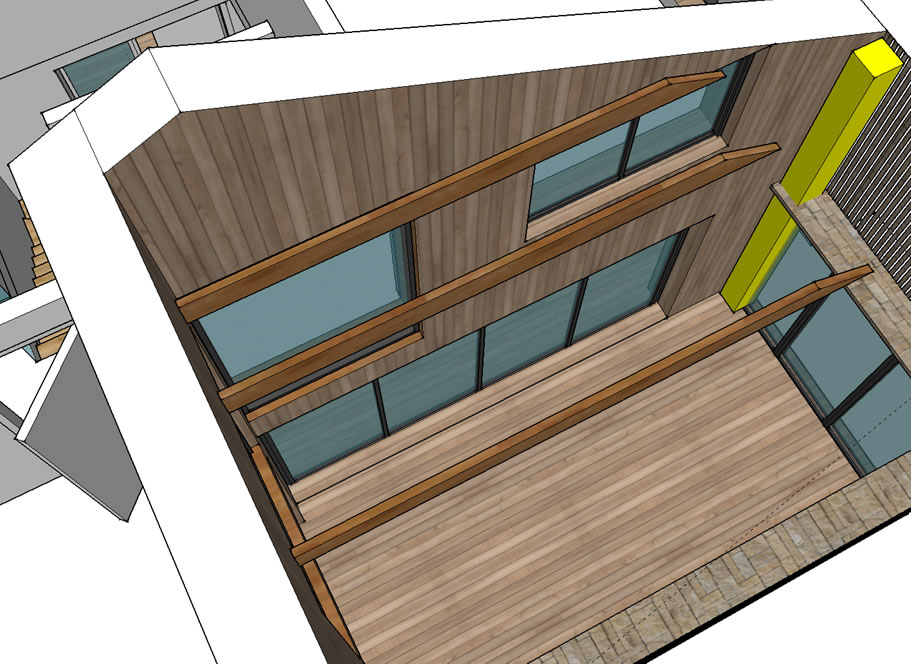

Have a look at this; This is a view into our Winter Garden from way above the roof. The yellow column represents (way out of scale) one of three vertical steels, each of which supports horizontals which in turn support the barn-style cladding. For clarity, I have omitted the other two verticals and all the horizontals. The winter garden is an empty area, outside the heated envelope (see the slats allowing air to circulate) The steel structure is linked to the house : how is my question? We could drill into the ICF and bolt it on that way or we could embed anchors in the ICF and drill the steels to suit on site The first is messier than the second. There is no guidance from the SE (Tanners) on how we should marry the house ICF and the Steels. But, (I have learned to ask), how hard can it be? I mean we could just pop down to Halfords and buy some cheap M6 nuts and bolts eh?........ well perhaps not.

-

Steels are up! After a fashion: with our build, there's always a twist so read on! First have a look at this....... We finished late last night SWMBO is really happy, and, to an extent so am I. The L shaped steel structure is secured to the floor with Thunder bolts, and will be secured to the wall with 16mm threaded bar embedded in the Durisol block. So far so simple. There was a gale last night , and attack of wind if you like : a useful gale, because it made me think hard. The purpose of this post is to ask you to check my thinking and offer relevant comments before I talk to the SE and Durisol. Many of you will remember the hiccup we had recently with the wall collapse (If not read this) And I am quite prepared to accept that that experience is colouring my thinking too much; but here goes. For those of you who are unfamiliar with Durisol block, here is a brief introduction - to understand the rest of this, it's worth a quick look (Links to an image search for Durisol: you only need to understand what it looks like) The vertical columns (steels) are attached to walls with threaded bar. It's that 16mm threaded bar connection that concern me. Because I cannot guarantee the continuity of the concrete within the Durisol blocks: it is that concrete into which I drill and attach the threaded bar and secure with Fischer Resin mortar One of the holes I drilled through the blocks showed that there was no concrete there at all. (The drill went straight through and out the other side of the block) Normally that lack of continuity will not not matter one little bit. But it does matter when the integrity of another structure depends in part on the attachment to the wall. Proposed Strategy Talk the issue with the architect (already done - strategy agreed) Talk to you all Think it through again on the light of the above and Ring Tanners (our SE) Ring Dursiol - maybe ask them to visit Agree problem solution : Talk to BC and ask for a visit before doing the following - Proposed problem solution Examine each of the current drilled holes with an inspection camera: checking to see 100% concrete continuity Attach the steel columns to those holes which 'pass' the test Create another series of attachment points by; identifying 5 further attachment points and exposing the concrete behind the insulation by cutting out that insulation entirely verifying the quality of the concrete drilling into it to create five more attachment points (one per hole) replacing some of the insulation and backfilling with cements and PVA mix. Bit of a faff, but I have realised that technical reassurance that (in this case) the structure is self-supporting is not enough. I need to know deep down in my gut that the structure is rock solid. The psychology is as important as the technical stuff.

-

Building on this thread, the question the fabricator has asked me whether we want the steels painted or galvanised? Well, I suspect that galvanising, while excellent, would be too expensive. The steels hold a structure (a curtain wall) that is external to the heated envelope, and they form one corner of the house. Has anyone got any experience of painting steels? What's the best paint to use? Is it the sort of job that a self-builder can do well enough? Got any trade names for an appropriate paint? We are about a mile or so inland (and more importantly down wind) from the sea. Blown salty wind is only a problem in winter. (I can taste it)