Search the Community

Showing results for tags 'radial'.

-

Apologies if this is a silly question but I can't find anything regarding the use of differing duct sizes on the site. The majority of rooms in our house require a single run of concealed 75mm semi rigid duct to satisfy building reg extract rates whilst keeping velocity low enough to minimise noise - at least in theory. Our kitchen/lounge/diner is larger and has a vaulted ceiling with a volume of 214m3 which is considerably more than anywhere else in the build. My calculations show the room needing 150mm diameter (or similar) ducts. This isn't an issue as we plan to use exposed galvanised in this space however I'm a little unsure if it is OK to mix duct sizes on a system or will it cause problems? Flow velocity at the outlets can be balanced in theory to within 1/2ms of other but the smaller rooms have an ACH of 2-3 whereas the largest room is 0.4. Is having such a varying range for this also an issue? Many thanks

- 7 replies

-

- mvhr duct

- galvanised

-

(and 2 more)

Tagged with:

-

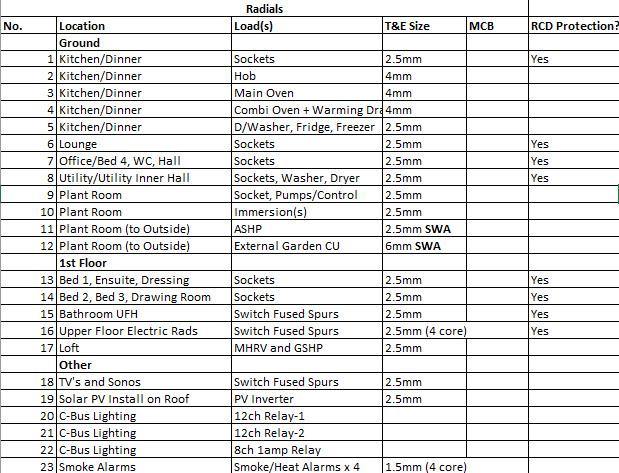

I thought I post this for a)interest b)to seek the views of the collective! I'm planning on radial circuits and my draft list is as follows. My first thought is it seems like a lot of circuits requiring a big CU! The last two columns are incomplete. Thoughts? (Circuit 16 is for fail safe only. No plans to install the electric rads initially. I've gone with 4 core as that matches the electric radiator control system we have in the flat (it uses the 4th core as a comms/control).

-

With all the talk about radial circuits I was just trying remember from previous discussions that it was difficult to connect two 4mm cables in the back of a socket? If I use deep back boxes as suggested then is it the way forward. I have a lot of 4mm cable and would like to use this for the sockets but do it as a radial circuit instead of a ring. TIA

-

Another pondering question from me I'm just thinking about first fix electrics. We're going for radial circuits for all loads, including lighting. The lighting will be controlled by Cbus Dimmers and Relays back at the cabinet as required. I've done a few 1st fix wiring jobs over the years (inc three with Cbus) and always used 1.5mm cable to allow for potential loads from say large banks of halogen downlighters. BUT, with the LED and low voltage being commonplace (and part of regs) I really cant see much point going over 1.00mm now for the lighting radials to each room. Max run is going to be circa 25m. All enclosed in service voids (uninsulated) behind pb. I know the benefits are pretty limited. Perhaps only; 1)Slightly Cheaper 2)Easier to run 3)More room in the cabinet. Am I missing something?