Search the Community

Showing results for tags 'mixer valve'.

-

Often thought about UFH control. Most systems are controlled on flow temp via a mixing valve, and with with room thermostat(s). Most use a mechanic mixer, some use an electronic mixer. With an electronic mixer, there is normally a temperature of probe on the supply pipe - but could you just look at water return temperature and then modulate the flow into the system via the mixer. So run a set return temp and modulate the flow temp going in. My thoughts are, it may give faster warm up times. It may automatically compensates for how much heat given off by the floor; flow/return dT changes, as floor to room dT changes, shows up in the return temperature moving up or down, so could you have more stable temps? Anyone any thoughts?

-

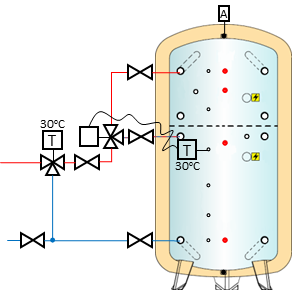

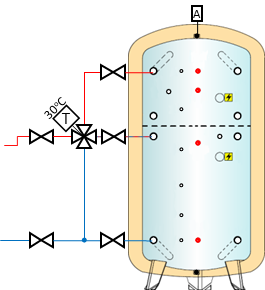

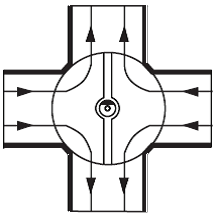

Whilst I deliberate over the tank design: In my 1 tank design I have included a 4 port mixer from the TS : The Lower part of the TS being around 40oC the top being 60-80oC (load dependant), however my UFH only requires around 23oC, so the plan was to take it out of the store at around 30oC and let the manifolds do the rest. However a 4-port valve with actuator will mix some from the top some from the middle and some from the bottom (I think) to achieve the desired output utilising a valve like this: This means that I am utilising high grade (expensive) heat when I don’t need to. Would it be better to use 2 x 3-port mixers as follows: The first mixer isolating the top (hot) part of the tank unless there is a drop in the lower part that needs boosting, then the second mixer doing the final blend with the bottom/return leg. Would this be more efficient? Also I could use thermos actuators (no electricity). Potentially I could do away with the TMV’s on the manifolds if I put the second mixer to the desired temperature, but that is for another day. Thoughts please.