Search the Community

Showing results for tags 'flow rate'.

-

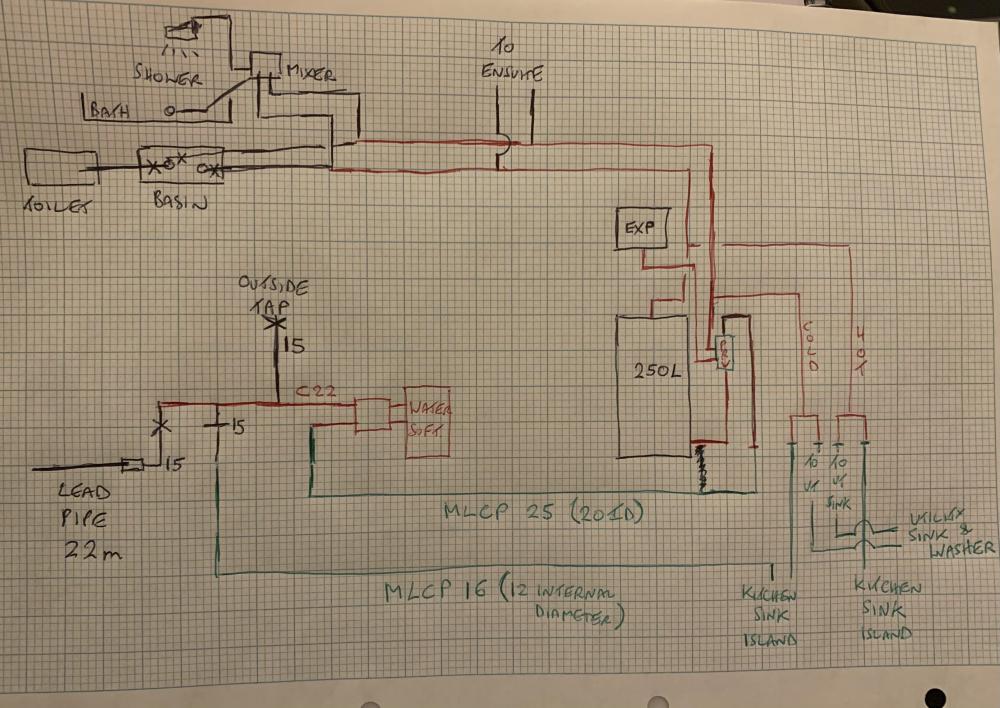

Old gravity fed water system has been removed and a new mains pressured UVC system has been installed by the builders plumber. ATAG Gas Boiler, 250L Gledhill Stainless ES Cylinder plus expansion tank. Mains supply currently via lead pipe connected to 15mm copper. Static mains pressure about 3.5Bar at outside tap connected directly to mains via 15mm copper/plastic. Flow rate from tap 20l/m. System has 3bar PRV fitted. Cylinder has 4.5Bar/95C over pressure/temp relief valve. System is fitted on ground floor. Questions/Issues 1/ Should there be a Tundish fitted as there is currently none. The overp/t relief valve has nothing connected to it at all and would discharge onto the floor ?! 2/we wanted to be able to run 2 showers simultaneously and still flush a toilet/use kitchen tap. Currently B/room shower gives static pressure of 2.8Bar and flow rate of 10l/m (hose only) or just 6.6l/m(from shower head/flow destructor removed). Noticeably weaker than old gravity system with 3bar(2.5bar at 9l/m) monsoon pump. If another tap is fully opened upstairs, shower static pressure drops to 1.4bar. Shower flow drops to 5.5l(hose only), 4.6l/m(through shower head). Hardly likely to support 2 decent showers at once. So what pipework should the plumber have installed ? Is the problem the pipe bores used, the pipe bends and Tees, the cylinder plumbing, the pipe lengths ? Very concerned now that plumber hasn’t installed adequately and not fit for 20 year use. How to know what exactly is wrong and how to fix it ? PS Current Pipes in sequence… 20m lead into property 15mm copper stop tap 22mm copper to water softener (not yet fitted bypass valve operating) 25mm MLC pipe to cylinder/boiler area 22mm copper to PRV, cylinder, and 22mm copper hot and cold to first floor landing. Then 15mm copper feeds from the 22mm pipe to upstairs taps and showers. 15mm Tee, 3 or 4 15mm right angles to shower mixer.

-

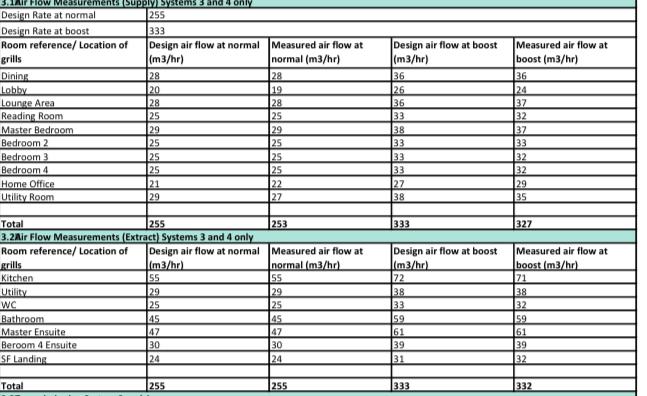

I have a Brink flair 400 My commissioning certificate says this: The options for my system (as commissioned by the supplier) are level 0. 50m3 level 1. 180m3 level 2. 255m3 level 3. 330m3 When I realised the system was a bit noisier than usual (as mentioned in my recent exchange with @jack), I started investigating what was going on and saw that it was operating at level 2, when I seem to remember that level 1 was recommended for default use. I have turned it down to level 1 and the system is definitely much quieter, hardly audible. I think level 1 is the correct setting I should run it at, but grateful if somebody could confirm this based on the commissioning certificate which definitely counts flow rate at the higher 255 m3/hour value.

-

I've learnt a hell of a lot from this forum over the last year or so and I'm so grateful to everyone for their help. On pipe diameters, I THINK, the following is best practice for selecting HW pipe diameters to come off a secondary loop, but just wanted to double check before I go ahead with it: showers 15mm hand basins 10mm baths, can be 15mm unless bath tub is super big and you have a high flow bath filler in which case case 22mm till fill the super bath more quickly My remaining questions are set out below (for context, we will have a UVC with about 3 bar of pressure and relatively good flow rate, although don't know what yet as Thames Water haven't done the upgrade yet; we currently have about 18L/min and they promised me something silly like 70 litres a minute, but I asked them to put it in writing and they refused, so I'm guessing it will be less than that): Does the same rule about hand basins apply to kitchen sinks? Any reason why 10mm might not be enough in the kitchen. Looking at my kitchen tap, it has very narrow 9mm hoses, so I can't see why anything bigger than 10mm would be worthwhile. It would just increase the dead leg that needs to be cleared each time it's used, but thought I'd better double check. what happens to an outlet further down the secondary loop when one opens the bath filler (which is rated at 33L/min) that is served by the 22mm secondary loop? Would the majority of the water in the secondary loop go to the bath meaning another outlet further along the secondary loop (i.e. further away from the UVC) that is trying to compete with the bath filler would really struggle, or would a fairly decent flow rate of say 25L/per minute, together with the 3 bar pressure from the UVC ensure that dynamic pressure is sufficient that the other outlet is still usable. should cold water pipes feeding each of these outlets always match the diameter of the HW pipe feeding them?

-

I have family to stay at present, and we have had a slight water pressure issue, which has prompted me to turn it up a little. the pipe is 15mm. Just a quick qu ... what would a typical max flow rate for a kitchen tap be when everything else if off? it is a monobloc. My first measurement was 8l / minute via the mixer tap with hot and cold flowing. I have now tweaked it and we are now at 9l/minute. The mixer tap set to cold is giving me 8l/minute. Is there a sensible number I should aim for? Cheers Ferdinand