-

Posts

359 -

Joined

-

Last visited

Personal Information

-

Location

Surrey

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Tony L's Achievements

Regular Member (4/5)

89

Reputation

-

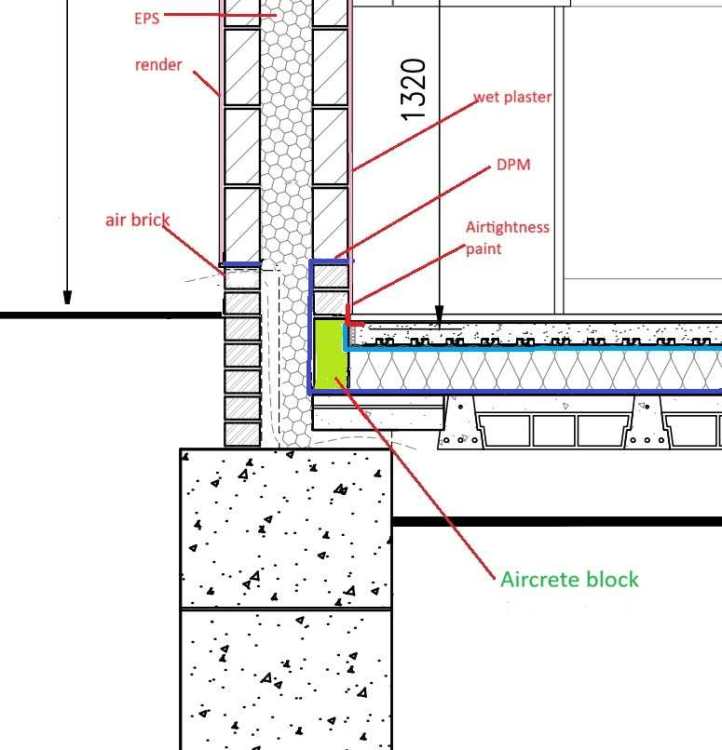

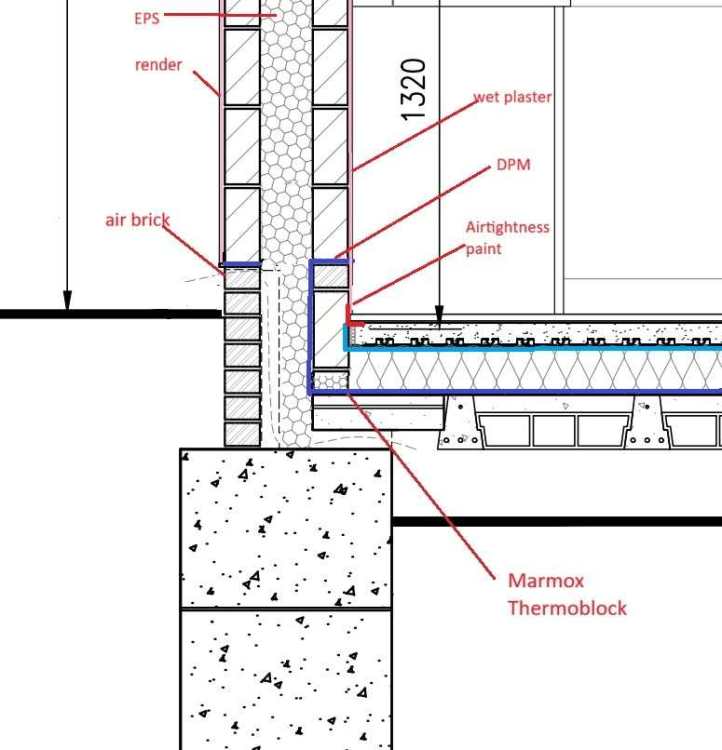

I need about 75 x 100mm wide Thermoblocks & 18 x 215mm wide Thermoblocks to deal with the perimeter (inner leaf) & internal block walls on my design. Based on the very first website I looked at, these will cost no more than £1200, allowing for overs. I haven't worked in the cost of the special glue, but neither have I deducted the cost of whatever might have gone where the Thermoblocks will go. Given the anticipated value of the completed house, & more importantly, the added comfort & other benefits, I'm happy to spend the £1200.

-

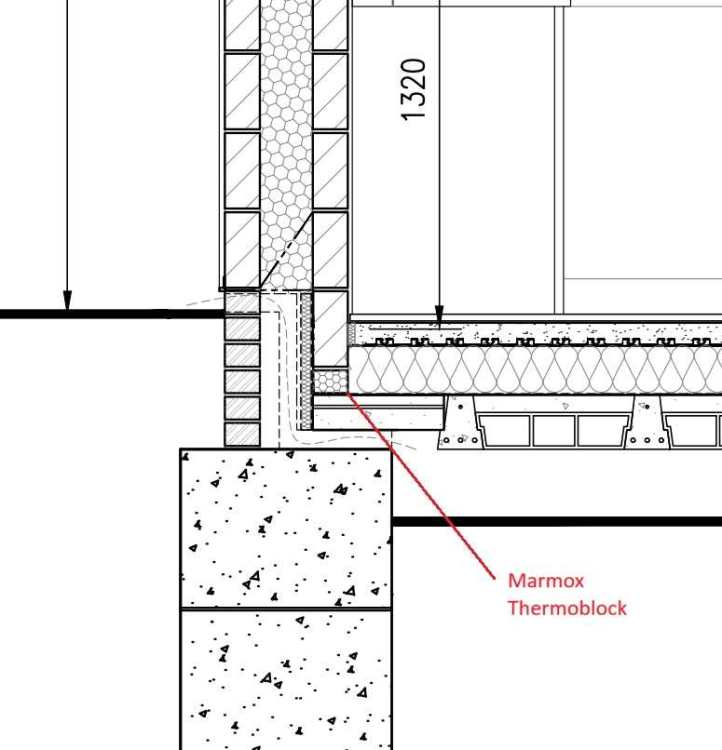

It is a bit. Yes, although, we're steering it back on track with our discussion of Aircrete blocks. Very good point - thank you. I amended the drawing with the Marmox & then thought, "I probably should have put the brick & the block that goes on top of the Marmox the other way round.", even though I didn't have the reasoning you have provided in my mind. I think keeping the change of materials below skirting level (or as low as possible) is another point in favour of a run of Marmox (65mm high vs 215mm for Aircrete). Blown beads. Thanks, @Gus Potter. When I think about it, I agree with you. I had only been thinking about water coming down from above, but I see there's the possibility for moist air to come up off the trench blocks. I think I need to find time for a new drawing & some more questions - I'll start a new thread.

-

I don’t know how either, but it happens. This wasn’t a thought experiment. It was a real experiment, with different brands of dryer running in a lab with clever chaps & machines measuring the particles that came out of them. I suppose it happens because the dryers leak. These particles are very small & they don’t need much of a gap to find their way out.

-

I think this is the best strategy if it works for you. I bought a heat pump TD for my mum. We installed it in her garage. I heard a reputable source explaining on the radio, TDs fill the air with microplastics & other pollution. I’m not having one in my house, although I plan to have one in an outbuilding, so I won’t have to breathe all the crap that comes out of it; also, my MVHR filters will go longer between changes & my utility/plant room (they’re the same room) won’t overheat so much in the summer.

-

Sorry, I can't help with this, but I must congratulate you on moving in, having completed your build so quickly. You're an inspiration to us all. & thanks for documenting your progress on here too - it's a real help to those of us who are not there yet.

-

is there a better kind of roofing / cladding batten?

Tony L replied to Alan Ambrose's topic in Building Materials

Yes. Dura Composites, who sell very nice, expensive cladding, will sell you some special aluminium batten bars. -

Aircrete version: When I did a cost analysis some time ago, the Marmox Thermoblocks didn't seem too pricey, for the perceived benefit. When I find time, I'll dig out my figures.

-

I have a very high water table, so I think this will likely make the ground colder than if the trench blocks were sat in dry ground. My trench blocks are going to be almost permanently damp, & I note @Iceverge's point about Aircrete blocks having to be kept dry, which is another reason I can’t copy the @Iceverge detail. I’d be grateful to hear comments on these two ideas, below. Could I wrap the DMP around the outside of the bottom of the inner leaf construction, as shown in blue? & sorry for the thread drift, @flanagaj. I hope you find my problem interesting & helpful, as you consider your build.

-

Thanks for your input @Gus Potter. When I say, “I designed the house.”, I mean, I did all the planning permission drawings & passed these over to an architectural technician, together with some notes about materials & build method (the Thermoblocks were part of my spec’). The AT has done the drawings my detail drawing was taken from, above. I expected him to do a lot better than this. Now I am spending hours & hours teaching him how to do his job properly so he can improve the drawings before they go to building control. My intention was to have EPS beads filling the cavity, with these going all the way down to the trench blocks. I imagined the EPS installer would drill through the inside leaf near the floor to fill the area below the tray. If I don’t need a tray & I can have two separate DPCs that would seem to me to be a better solution. This was suggested to me on an earlier thread, but I thought the 2 separate DPCs suggestion was just for below my windows. If we can use 2 separate DPCs the whole way round the house, that would be great. Are you sure omitting the Marmox blocks is a good idea? This is going to mean all my walls will be sucking heat out of the house straight into the ground. I can’t follow @Iceverge’s detail above (thanks for putting this up, @Iceverge) because I’m building my inner leaf off the top of the B&B, which has already been built. Here’s a picture of it during construction. As discussed here previously, the cowboy builder sat the B&B on trench blocks, instead of on dense blocks (which were on the drawing), so there’s no cavity beneath the level of the B&B, & although he put the beam ends on DPC, he then bridged the DPC with mortar - see below. The bit on the right of the picture, with the light coloured slips, is where the air brick periscope feeds air into the B&B void.

-

I shouldn't think so, but I don't really know, because I didn't learn about ground bearing slabs before I designed my house. I should think with a ground bearing slab, you'd have a continuous platform of insulation to separate the top part of slab (including the bit the walls are built off) from the bit that's in contact with the ground. In my case, I have concrete foundations with trench blocks, & the trench blocks support a beam & block structure, so my inner masonry leaf would have a direct connection to the ground, through low R-value materials, were it not for the Marmox blocks. Perhaps I should have left this question for somebody more knowledgeable than me to answer, but it seemed to be directed at me.

-

That's exactly what I have planned for my build. I also have a couple of dense block internal walls which will sit on Thermoblocks. One of these will be built from blocks laid flat, so it will be 220mm thick & will have 220mm Thermoblocks beneath. The idea is, if there's any money left, I can hang a floating staircase from this wall. & I'll have super THERMAL MASS - there, I said it too. Now we'll both be in trouble when @SteamyTea reads this thread. Here's my detail. Yes, I know my Arch Tec has drawn the air brick at the same level as my patio, with virtually no insulation below DPC level & the periscope sitting in the middle of the cavity instead of up against the outer leaf. I have already told him off. He really is rubbish. & I engaged him in May, & I'm still waiting for my second draft drawings.

-

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Tony L replied to fatgus's topic in Heat Insulation

This must be why Veka's T&Cs say, "In the absence of any express warranty to be specified by the Seller in respect of Goods which are not “white PVC -U profile” no warranty shall be given in respect of the Goods.". If you want a warranty for a colour, you have to ask them for one, & I don't suppose it's going to be 10 years, which is what they're offering for the white PVC-U. -

Target U-values… Cost/benefit sense check… What am I missing? 🤷🏻♂️

Tony L replied to fatgus's topic in Heat Insulation

I had a look at the Veka website, earlier today, following @Iceverge's tip, above. They offer some colours in what's called "Feinstruktur" finish, which they say looks like aluminium. -

Yeeessss we bloody done it.

Tony L replied to Russell griffiths's topic in General Self Build & DIY Discussion

Well done, Russel. That looks fabulous. I hadn't realised you weren't already in.