-

Posts

49 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Space Race's Achievements

Member (3/5)

1

Reputation

-

Vapour barrier thoughts on renovation

Space Race replied to Space Race's topic in General Self Build & DIY Discussion

Yes. They started with a log building (similar to mine), 3rd pic down is their vapour barrier, 2nd and 4th pic they have added the timbers in which batts will sit, 1st pic shows batts being installed. 5th pic shows their breathable membrane and battens ready for cladding. -

Vapour barrier thoughts on renovation

Space Race replied to Space Race's topic in General Self Build & DIY Discussion

Thanks, I'll take a look at that Intello. Assume it's one of these smart membranes. The pics are not mine but the clear plastic looks to still be there after the insulation frame has been fitted, Assume its their vapour barrier. Someone else used Ekovilla Smart X but I've not seen this as readily available to buy as the Intello you suggest. Because I'm working on this part time and solo (slow A.F), dealing with Highland weather and all my layers are external, I'm concerned about trapping in moisture -

Finally on the back end of restumping our 12 year old log cabin and starting to think about details for the insulation and overcladding of the walls. I’m following the idea shown in the attached pics (photos from logcabinkits.co.uk) but worried the vapour barrier would trap any existing moisture in the logs. Improving the air tightness would be great but struggling with concept of wrapping wood in plastic. Would one of these fancier “smart” barriers be better? Any suggestions? The cabin already has some rotten logs I’ll need to cut out and patch and the North face won’t dry out again now whilst summer. Any thoughts from the more knowledgeable on this? For clarity in case its not clear, From inside to out 68mm logs Vapour barrier Insulation frame for mineral wool batts Breathable membrane 25mm vertical batten 25mm horizontal batten Vertical timber / metal cladding

-

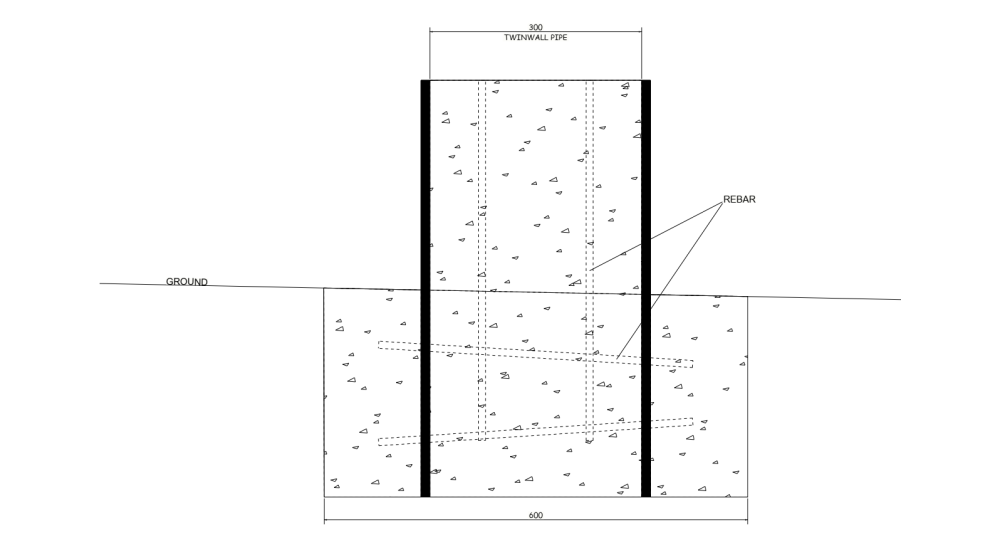

Do you think a similar idea using a 300mm plastic twinwall pipe would work. Say 600mm square hole with the pipe in the center, 2 or 3 lengths of rebar through the pipe and fill both the hole and pipe with concrete?

-

We have a 10x5m log cabin that's raised off the ground on (sleeper type) timber posts. These posts are now at varying stages of rot and I'd like to replace them with something a little hardier. As a side note I'm also looking to insulate and clad externally so these new supports will project out 100-150mm around the perimeter. The ground level slopes and the attached drawing shows the gable end where the ground is at it's highest with only 110mm clearance. On the opposite gable (not shown) the grounds much lower with a 450mm clearance. It's tricky as I'll need to prop the frame (possibly jack, depending), Remove the rotten leg and small pad its sat on, then dig the new foundations in the tight space between floor joists. I'd only be able to do a few holes at a time due to the propping and if I fill each hole with concrete I've a further wait before being able to build off it. I was thinking about using hollow concrete block stacked on top of each other in the hole with concrete poured both into the hole as well a inside the block itself, more to tie them together than anything. This means I could get the new support done in one hit but the bottom block would only be encased in concrete, not sat on it. Has anyone any thoughts on this? Feel like I'm too close to this now with overthinking and unable to see the woods for the trees SH_Gable Foundations RHS.pdf

-

Log cabin - Possible renovation to insulated office

Space Race replied to Space Race's topic in Garages & Workshops

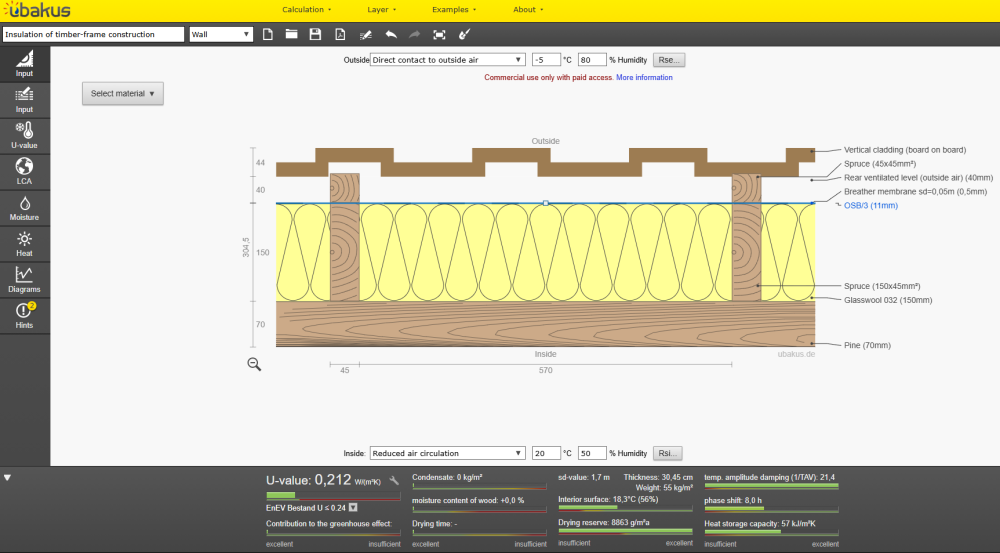

So many builds i look at use OSB so I've either done something wrong with my Ubakus selections (likely) or the analysis is wonky. I tried a few of their other OSB options as well as ply and MDF. The only option that removes the moisture issue is MDF 500kg/m3 -

Log cabin - Possible renovation to insulated office

Space Race replied to Space Race's topic in Garages & Workshops

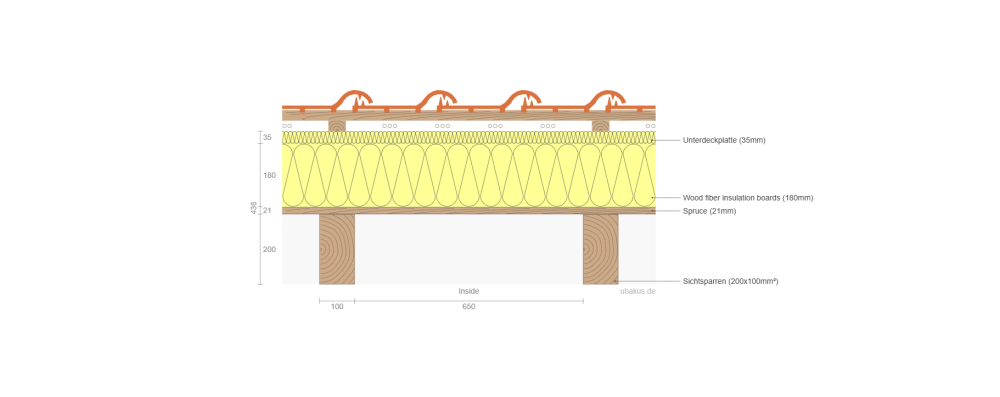

Been looking at how best to go about cladding and insulating externally with current thinking as follows, Build a new 6x2m frame filled with 140mm thick roll of Frametherm 32. Counterbatten the frame and clad with vertical board on board cladding. I popped this all into Ubakus (which I clearly don't understand) and all looked fine until the OSB layer was added. TBH I'm not 100% if this is needed but if it is, Can anyone explain what I'm seeing with the Moisture issue? From what I've read the OSB sheathing gives the frame its strength, That said my frame will not be supporting a floor or roof, Just the insulation and cladding. Would I need this? Thanks -

Log cabin - Possible renovation to insulated office

Space Race replied to Space Race's topic in Garages & Workshops

Guessing It’s this one by JohnMo? Some useful info, Thanks https://forum.buildhub.org.uk/topic/31017-summer-house-insulation/ If going the route of upgrading the cabin I’d want to clad externally though with a membrance keeping the rain out of the logs. The movement of the logs around doors and windows is a problem. Would not be happy spending so much to insulate the building and then leaving large gaps around windows and doors. In terms of the supports under the joist base It looks like I’m either digging new post holes or some kind of ground screw. On the whole a new build elsewhere in the garden would be more straightforward but still researching -

Log cabin - Possible renovation to insulated office

Space Race posted a topic in Garages & Workshops

Started looking at options for creating some office space at home, Usual suspects, House extension, dedicated garden office etc and wondering if renovating an existing cabin would be better use of funds vs a new purpose built garden office. In the garden we’ve a 10x6m log cabin style summer house that’s not getting as much use as it might. The cabin came with the house and was erected about 11 years ago It’s constructed from 68mm logs and sits on a raised 145x45mm (6x2) joist base. The base is supported on timber posts (assume post mix concreted in), Height from ground to floor varies but It’s around 450mm at high point and well ventilated. It’s been maintained but the timber doors and windows need replacing and there are a couple of spots where driving rain gets in. If going the cabin route I’d want to * Upgrade / Replace support posts for additional weight and ensure these will last for many years to come. * Insulate floor * Insulate walls * Insulate roof. * Replace doors and windows, possibly changing the existing apertures. * Clad the outside if the wall insulation was external. Cladding the outside would also sort the rain ingress which i understand is not unheard of with these log buildings. That said, Insulating the inside seems like it would be much easier at initial glance. Not sure if linking videos is permitted but this shows a similar scenario with a cladding detail that would work aesthetically. I’ve not looked at this too deeply though and open to options. Also worth pointing out, Our cabin is very similar to the one in the video but I’ll take some pictures once the snow has cleared and take a closer look underneath at the base frame. The attached image is the kind of thing we have Has anyone done anything similar? Any advice? Would the savings (if any) make sense over building a new purpose made building. I’d be very interested to hear your ideas on how to deal with upgrading the support posts given this is an existing building with limited access to the underneath. The floor can be taken up but I’d still be working between joists. -

Lawn edge recommendations (Core Edge / Everedge)

Space Race replied to Space Race's topic in Landscaping, Decking & Patios

Yes the plan is to sink it so top of edging is just under the lowest cut on the mower deck so It can be mown over. No robot mower, Ride on -

Lawn edge recommendations (Core Edge / Everedge)

Space Race replied to Space Race's topic in Landscaping, Decking & Patios

Thanks for the code and info, Good to know they did the right thing by you. We’ve quite a bit to do so I’m still working out final meterage and not settled on the thinner or thicker trade stuff. If the mower bent it out of shape I’d be annoyed. -

Lawn edge recommendations (Core Edge / Everedge)

Space Race replied to Space Race's topic in Landscaping, Decking & Patios

If it was just a case of buying the plate cor-ten and having them cut it to length I’d agree 100%. They’d need to weld pins to the plate though, Otherwise I’m thumping long lengths of deeper plate into the ground. They’d also need to weld lugs on so I could join each length. Between the time/labour fee and the fact it would probably be an inferior design when all said and done, I’ll stick with the edging stuff. -

Lawn edge recommendations (Core Edge / Everedge)

Space Race replied to Space Race's topic in Landscaping, Decking & Patios

Looks lovely! Yes can imagine the powder coated stuff taking a bashing and soon looking tatty. I noticed the local National Trust property used the cor-ten finish and seemed to work well. Sadly no gardeners around to ask. I'd weighed up using timber but we've so much of the stuff already around the garden I'm looking for less rather than more to maintain. I feel it will be easier to get the level of the core/ever edge set right so we can mow right over the top. Who did you order from and did you choose to keep those two boxes or did they refuse to take back?