-

Posts

21 -

Joined

-

Last visited

Personal Information

-

Location

Fasnagrianach, Highlands

Recent Profile Visitors

1845 profile views

Longjock's Achievements

Member (3/5)

0

Reputation

-

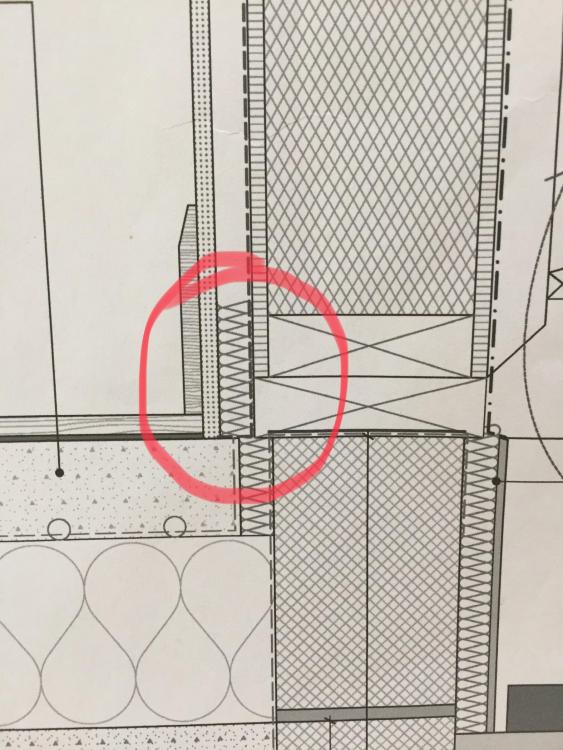

This is the detail showing the internal 25mm pir upstand. As it’s separate from the one in the screed (and internal of the vcl) I was thinking of screwing it to the sole plate but using insulation washers to help with getting the contact face tighter. As in the mock-up in the other pic

-

Already prepped for that ? ProDave having read your advice on other posts. I’m using a mixture of 25 and 50mm battens where appropriate

-

Pir will be on the inside. Already has rendered insulation on the outside block plinth covering the outside face of the sole plate. Drawings show another 25mm on the inside face. Floor is already screeded up to the bottom edge of the sole plate. The strip I’m planning to instal will sit on top of this but below a horizontal batten.

-

Hi All, Just planning on the fixings for the service cavity battens and was wondering what is best for minimising the leakage in the vcl? Ours is a SIPS with 1200 wide panels. Do I still place the battens at 600 centres or just where the panels meet (where the timber joints are)? Also I am putting a 85mm high perimeter strip of pir around the sole plate and was wondering what fixing to use again worrying about penetrating the vcl. All suggestions welcome!

-

Hi All, Does anybody have a 7.2m working height / 5.2m platform height tower for sale in the North? Cheers

-

Hi All, Our architect's detail of our VCL is a layer of Proctor Reflectatherm sealed with two runs of their (butyl?) Probond RG tape in the lapped area. No mention of foil tape. I have actually picked up some Protect VC Foil Ultra (without the built in tape) for a great price and was wondering if the above method would work with this membrane? I will, in any case, foil tape the edges - regardless. The Protect website just mentions using their foil tape at joints, only to place the joins under the internal battens. They do have a double sided tape (doesn't look like it's butyl though) that could go between the lapped areas for extra sealing, but its a lot more expensive than the Probond RG tape. Or would another butyl type tape do the same job. Any thoughts or advice on what others have done? I'm using the Illbruck I3 set-up with the windows.

-

Self-Build with UK outside the EU

Longjock replied to Ferdinand's topic in General Self Build & DIY Discussion

Yep, I read that also. I was just wondering if anyone had actually done it yet and how hey were 'presented' with the tax bill? By the courier or what? I've had a good look at the product listed and I'm not sure it's even the right one now, so will likely be buying from the UK. -

Self-Build with UK outside the EU

Longjock replied to Ferdinand's topic in General Self Build & DIY Discussion

So, has anyone ordered anything this year and been hit with the import vat yet? I'm looking to get some Illbruck tape from a German supplier on eBay (as not only are the items cheaper than the UK suppliers but the postage costs are also - Scottish Highlands surcharge!!! The value of the order will be over the £135 threshold though. -

Juliette balcony fixing to sips

Longjock replied to Longjock's topic in Structural Insulated Panels (SIPs)

I saw the thermal break fixings on Balconylife’s website so have sent them an enquiry. Let’s see what they come back with. wasnt that keen on the look of “button” type fixings myself as I prefer the linear look, but the wife’s happy with them so that’s decided for me then! Be interested to see what you come back with. -

Hi all, Has anyone fitting a Juliette Balcony to the exterior of a SIPS panel? If so how did you go about the fixings? i take it that it will be necessary to beef up the mounting areas but with what? We will have timber cladding and it’s associated void to cater for (approx 63mm plus 20mm cladding).

-

Rendering foundation blockwork below SIPS sole plate

Longjock replied to Longjock's topic in Plastering & Rendering

Hi guys, finally getting round to starting on this. I’ve primed the blockwork ready to stick the eps on to, but I’m not sure about the dpc sticking out from under my sole plate. Do I tuck this down behind the eps board or do I trim it off or what? -

Rendering foundation blockwork below SIPS sole plate

Longjock replied to Longjock's topic in Plastering & Rendering

Cheers @nod , the shingle up to the render is the plan. I’ve just looked at the HP12 and it says it’s good for fixing the eps to the substrate, but are you saying to then use this as the following basecoats (with mesh)? Do you then put a top coat on or just paint? I’ve never had to look at any rendering before, hence the understanding of this process. -

Rendering foundation blockwork below SIPS sole plate

Longjock replied to Longjock's topic in Plastering & Rendering

Yep, been looking there. I’m giving them a call on Monday for advice. The only other info i’ve picked up is using mosaic render but that stuff is so expensive. -

Hi guys, I've got to crack on with making the decision on what to use for the area of blockwork below the sole plate. The drawings show to use EPS and Stolit K up to the dpc level but after speaking further to the architect, he has suggested in carrying the eps up over the sole plate to aid with the thermal bridging in that area. The external walls will be vertical timber clad down to this level so the top surface will be hidden and the lower edge of the rendered area will have shingle up to it in the 'drip area'. My dilemma is that everything I look at online about rendering on EPS is based on full walls, rather than this area. Do I have to follow this process (starter beads/adhesive AND mechanical fixing etc.) or is there a more cost effective/simpler way of getting the job done. All the local 'trades' round here, only ever talk about sand and cement but I know this won't work with EPS. Any help given will be appreciated.

-

That is what we’re looking to do. Exactly what I needed to know. Thanks guys. The discussion we’re now having is whether to paint the reveal board to match or to leave it as is!!!