Kernow

Members-

Posts

69 -

Joined

-

Last visited

Everything posted by Kernow

-

For a Self Build VAT reclaim (new build), has anyone successfully achieved this before your completion certificate has been issued? We would like to put in our VAT reclaim before we attain our final completion certificate from building control. If anyone has managed this what documentation did you use in the place of a certificate? Many Thanks

-

Not a lot, I'll have a measure up, Probably only a few sq metres worth

-

Yes I have noticed this, but a lot of the local suppliers don't stock it as standard so have to order it in with a minimum order value

-

Where has everyone been sourcing their compacfoam 400 from? Or alternatives As I only need a small order I'm interested to know where everyone is getting theirs from. Thanks

-

We are about to get our floor screeded with cemfloor liquid screed. So that we can get our levels exactly right for bifolds etc, what allowance should I give for the following floor make up? 9/10mm porcelain tile adhesive ditra mat adhesive 55-65mm screed We can tweak the screed thickness to make sure we are at the right height, but unsure on thicknesses etc. Thanks

-

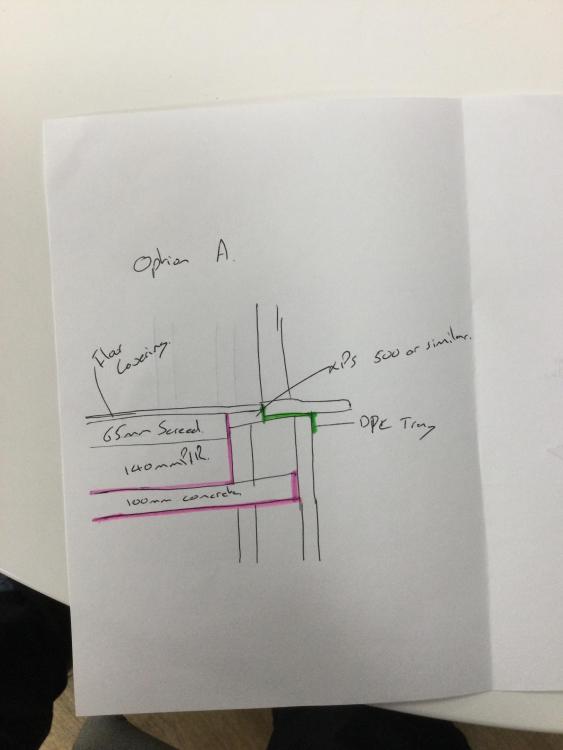

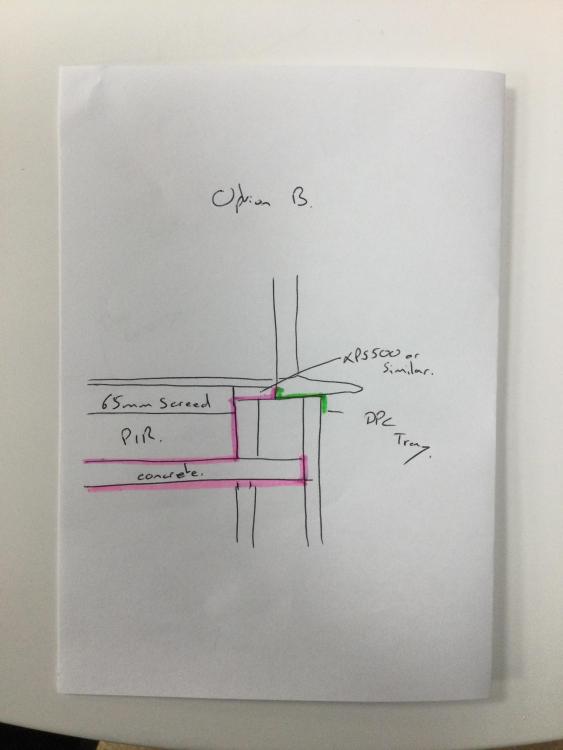

Starting to think about getting insulation down ready for screed. we have the following floor build up: 100mm reinforced slab 140mm pir 60mm liquid screed porcelain tiles floor covering Question is will the screed/insulation be strong enough to take the staircase and newel post weight or will added support be required? Just a standard staircase, nothing fancy. If it needs supporting what’s the best way to be this? Replace PIR with something like an XPS500 or is there an alternative solution? Thanks

-

Currently thinking of either of these options, Option A would be easier to detail as I thinking fixing the small piece of xps500 over a radon barrier could prove challenging. In hindsight I know I should have used xps500 under the sill as a cavity closer, but too late for that now. Option A Option B

-

Thanks Jenki, That’s useful, I hadn’t considered the use of a higher compaction rated insulation in the threshold. That should help eliminate the cold bridging detail I was worried about. Nickfromwales, our details around the door threshold/doc are very vague, but we are basically having a 2 layer radon barrier, one under a ground bearing slab, then one internally, lapped up the wall.

-

I would be listening to the roofers that say your membrane needs replacing. Assuming your gutters aren’t blocked and overflowing, then even if these leak it shouldn’t be causing that problem. looking at your roof you don’t have enough overlap on your tiles, so wind blown rain is getting under your tiles and through a perished membrane.

-

Does anyone have any drawings of how they have detailed their doorway thresholds when building with a polystyrene ICF. Specifically radon barrier and cold bridging details? I’m not totally convinced my detailing is best, but it may be too late for any other options. Thanks

-

Thanks, have had a quick look. I think I will be ordering some bends, as some of ours are definitely tighter than the recommended 150mm radius. Yes I understand that large smooth curves are better, it’s mainly on the vertical to horizontal junctions that are going to be a bit tight. Labelling - good point

-

Currently in the middle of DIY installing our MVHR system, and just wondering about the bends. Some of our 90 degree bends seem a bit on the tight side, how tight have you bent your pipes? I see you can get 90deg joints, am I better of getting some of these or are tight bends ok? We are using ubbink 90mm semi rigid round ducting. Any feedback would be appreciated.

-

Yes through the tongue is the standard why of using them, just not fully convinced that face fixing with them will be adequate, as the head is so small. Thanks JamesP, looks good. Hardly noticeable there. Thanks

-

Interesting, if you used tongue tite did you fix them through the face of the board or through the tongue? Do you have any pictures of how they look now?

-

I had considered screwing it, but adding up the screw cost of £800-1000, versus a nail cost of approx £200 it’s going to be nailed. Probably going for hand nailing, as it will all be face fixed, so keen on the improved accuracy of hand nailing it. Labour is free, if a bit tedious

-

What nails would people recommend to face fix Siberian larch. obviously stainless steel, but lost head or round head? I prefer the discreet look of a lost head nail, but has anyone had any issues with pull through or movement with lost heads? Thanks

-

Can anyone recommend a good air tightness tape for using with EPS based ICF. we have built in Nudura and looking for a tape for the window/door junctions? Thanks

-

Thanks, yes I had thought of an aluminium trim, was just wondering if anyone had any examples where they had done similar. No worried about mesh etc as like you say save a steadying, likely too draughty for anything to live in there

-

We are going to be having a section of timber cladding over render on our build. Cladding will be open joint random widths, over a black tyvek membrane. How has everyone dealt with the bottom detail where the cladding and render meet? Has anyone used aluminium trim, so that you don’t look straight up behind the cladding, and also to tidy up the bottom edge of the membrane? Or have you just let the membrane flap and rendered up behind the timber? We will be having aluminium trims over window heads etc, so not a problem to get more made up. I’m also aware that we need to keep the cavity behind the boards ventilated. Any info would be appreciated. Thanks

-

Has anyone got any experience of using British Grown western red cedar or larch cladding? original plans for our new build were Canadian Western Red Cedar, but now that costs around £100 sq m we are looking at other options. Both British Grown Cedar and larch come in at about the right cost, but I am concerned about the knot frequency/size on both. How unstable is British grown larch? I am assuming cedar is the more stable. Which has the most consistent weathering when left untreated? Any experiences would be great. Thanks

-

Thanks for all the feedback and thoughts guys. I know it’s a hotly debated topic so it’s interesting to hear so many different opinions from experienced builders and self builders with such vested interests in there homes.

-

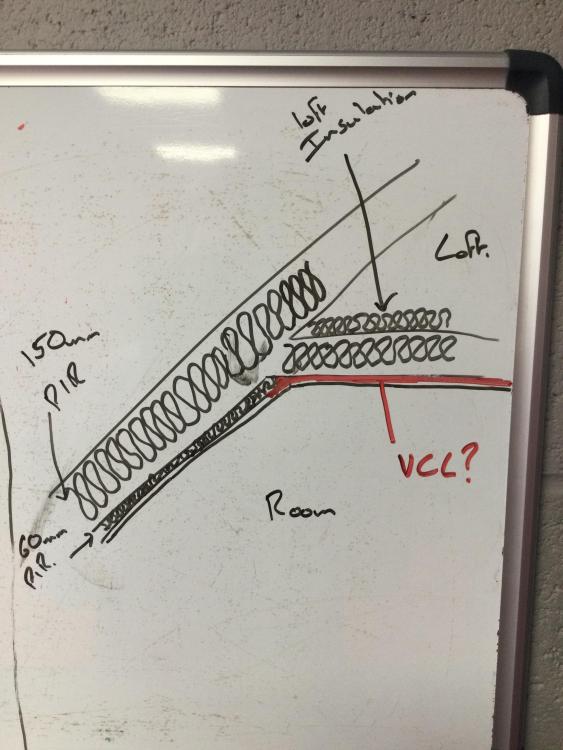

What is used on the flat ceiling parts? I understand the lack of need for it on slopes with pir, it just adds an extra layer for condensation risk. I can see the benefit of both ways, I have come across properties in the past with excessive condensation on the breather membrane due to too much moisture travelling upwards, but also times when the vapour barrier has caused sweating. It seems there is no definitive answer on this one

-

Perhaps the attached photo makes more sense? pir between trusses stops just above ceiling height. Loft space to be unventilated

-

Woulld you say this is also true on flat ceilings with loft insulation as opposed to sloped ceilings with PIR? I know it’s a highly debated topic

-

Thanks for the responses, Yes I’m happy with taped joints being sufficient on sloped ceilings What about on the flat ceiling under loft insulation?