lizzieuk1

Members-

Posts

98 -

Joined

-

Last visited

Everything posted by lizzieuk1

-

Hi all, Having thought we had the best option for our roof sorted with an I joist design we're struggling to find a supplier who can design & supply the I joists. We have loft rooms so need open spans Has anyone got any suggestions/contacts who can help? Our SE has designed steel ridge beams to support the I beams but need a layout etc sorting. TIA

-

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Sorry, i meant fan coil unit! -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Tricky to decide the best solution. If we go Air con then a. The cost and b. We're only doing ufh on gf so then no option for supplemental heating on ff&sf. Yes, ashp but installed quote for (8) heat coils is 10k! If its that much we could get an mvhr heat/cool module and as installing the ducting anyway can upgrade to 100mm insulated ducts. But, is it as good as heat coils??? How easy are the heat coils to install? How do you account for them on the ashp sizing?? So many questions..... -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks JohnMo, all good info. Wonder if there's a way of dehumidifying along the route to help the cooling? -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Yes, we are going to look at external blinds - still in early stage of costing these, but had experience of them at my parents place in France so know they work well. Good to hear the mvhr has helped - the Zehender comfoclime looks interesting as can actively cool or warm incoming air which could help fill the gap of wanting some comfort cool/heat on ff&sf rooms. -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks Mike, we're not too bad on the calcs for Overheating- just a small loft room that needs an extra 10L extract to pass. Roof will be blown cellulose & we've no huge areas of glazing. We will use the ufh on gf to cool but have 3 floors so wanting to get something on ff & sf if we can to offer a bit of extra heat/cool if needed - 8 heat coils installed coming in at 10k on first quote so feel there could he a better option! -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I know previously it wasn't especially useful but wondering what the new offerings are like. The Titon Cool plus Q has a 3.3kW total cooling, or Zehnder ComfoClime which has 1.7kW cooling and 1.7kW heating. We were looking at heat coils for heat/cool on ff & sf (ufh on gf) but so far at 10k install that feels pretty steep! (Would be 8 coils to do so quite a few and not sure if we can do the install though still investigating that) -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks Nick, I've only had a rough overview cost so far, we thought it was quite cheap as well. From memory (bit hazy though) I'm sure he said they use 50mm ducting which rang alarm bells for me straight away! We're pretty sure we will self install a system now to both control quality and cost, also think we are wanting to add in some comfort cooling/heating so into the realms of insulated ducting etc. -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks, that's all helpful info. We are weighing the options on install - happy to diy it but equally if the installed cost isn't much more then will go with that (we have lots of DIY to do on this one!) -

Ubbink - what are they like?

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Thanks, good to know. How does £8.5k sound for full supply & install (for ref its 420m2, 3 storey house) One worry is I'm sure the guy said they use 50mm ducting, which sounds rather small but I may have misheard so will check! -

Airtightning roof - Membrane tips and tricks?

lizzieuk1 replied to boxrick's topic in Heat Insulation

Are you doing the blown cellulose yourself? We're hoping to self install so interested to get some info if you are. Watching the video of a U.S one they use a semi transparent fabric (like the ones under sofa bases) stapled on then fill. I guess you'd need to fit an air tight membrane after that though. -

Feel I should know the answer already but can't seem to settle on one! Ideally, wanting to do our own ufh and solar install and, if possible, source the ashp/cylinder etc and get local plumber/sparky to install, sign-off that and necessary solar bits. My confusion lies with getting our bc sign-off if the ashp & solar isn't mcs installed. Our last builds we had mcs installs and handed certs to bc so all easy but, far more costly for our own home build that we need to budget far harder on! What are the bc 'hoops' required for that sign-off without mcs certs?

-

Resurrecting this a bit. Looking at the website it seems you jeed a few 'extras' to do this via self install. How did you manage those?

-

Best way to get new supply to house.

lizzieuk1 replied to lizzieuk1's topic in Consumer Units, RCDs, MCBOs

Yes it will be once the new one is built. -

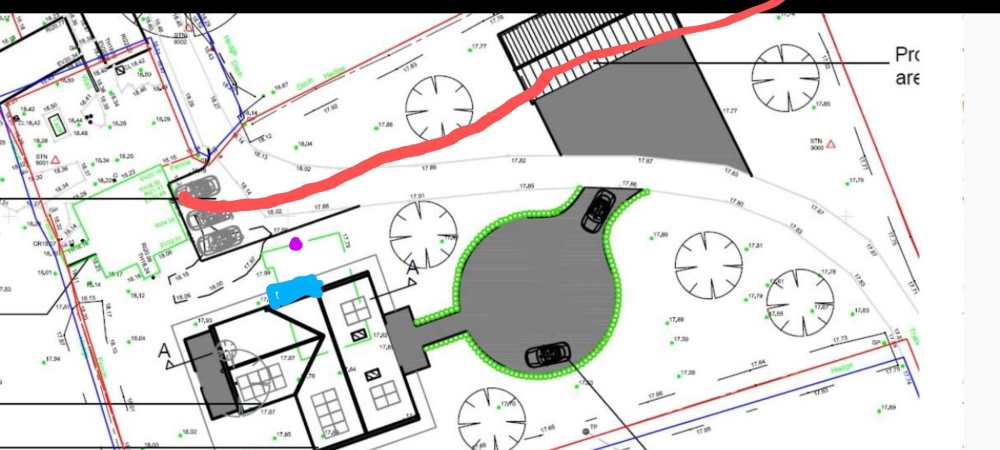

Morning all, So we're trying to work out the best way to provide our new electricity supply. We're still living in the old house whilst building the new one and wondering if there's a way to connect the old cable to a new one once we are ready to move from old to new. (Green is old house & old garage) The red line shows where the current supply is and we will need it to go to the blue box area where our utility will be. There is currently also a feed to the old garage (purple) from the current house. Any ideas of the best options for new supply? Is it even possible to join a new wire to extend the old supply 🤔 or are we better running a completely new cable - bearing in mind the old one currently runs from the East boundary under where the new garage will be? Slightly worried that will cost an extortionate amount though!

-

Mvhr design & costs

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

We've certainly had that experience previously, but, as not installed mvhr before or had to deal with part O, I was feeling a bit out of my depth disagreeing with him at the time. -

Mvhr design & costs

lizzieuk1 replied to lizzieuk1's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Yes, my thoughts as well! I'm not sure why he thinks bc will need the mvhr design at this stage - we're keen to get the basics submitted but not going overboard so we can actually start building! -

Morning all, So architect has suggested it better to get the mvhr design done for the regs submission, says it will assist with meeting the part O Overheating requirements. Obv something we need to sort anyway so looking for advise/ suggestions for design & expected costs. We are happy to install to save costs there though. Is bpc a good start? Not sure if I'm up to doing the full design but happy to have a go if it's achievable - bit concerned about time as need it fairly soon for bc submission and got another project on the go currently.

-

Did you use I-beams for the rafters?

-

We will have plenty of options for the mvhr etc in the eaves void either way though. Both will need the ridge steels and I'm wanting to compare costs. So far from 1 posi supplier the roof will be around 12k 😬

-

I'm struggling with the i joists, again! SE happy to sort a steel ridge detail but, he can't design the roof for us. So where do I go for that? Who can I ask to design it? Lots of truss manufacturers will do with trusses & one I found will do posi but not sure who to as for the I beam design! Any ideas?

-

We've not got that far yet! Been preparing for ages so info gathering brought us to vacuum glazing. AFAIK there are 2 available, Landvac and Fineo, one has more spacers than the other and a slightly superior u value. When we looked at the landvac in a window at the Homebuilding show it was very hard to see the dots, certainly from a distance they were invisible. Worth popping along to see some in frames if you can. We're yet to decide as really don't want to go for timber sashes, mostly because of air tightness but also due to ongoing maintenance. Finding a supplier for upvc sash with vacuum is proving a challenge, seems far easier to get them in timber though! We are going to look at dummy sashes along with the Quickslide - though Nod has a poor experience of them so we need to be quite critical with viewing them. I believe they now have a rating of 4 for air tightness so wonder if they have refined the design - that will be a question we will certainly ask. Issue is we can't get a 3g sash - which we'd prefer- but can get 3g in the dummy sash so will see how they look. On our last build we used Residence9 3g and they looked very convincing as far as timber look goes - certainly worth a look if you have any non sash & want to consider upvc. Hope that helps!

-

That's certainly worth thinking about, what would the cold bridging issues be though? I'm wondering if we could add a steel at first floor ceiling that we could take a post up from to support the ridge, do you think that's a viable option?

-

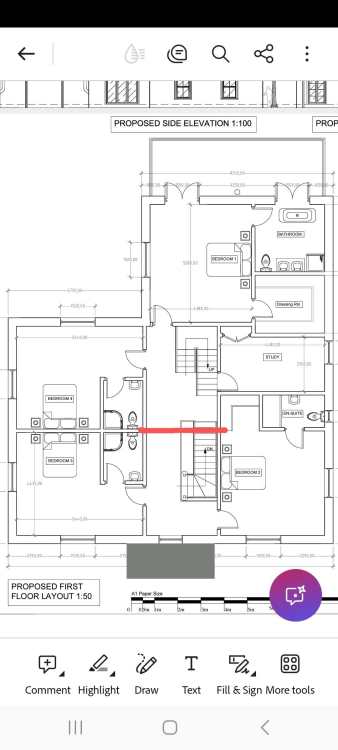

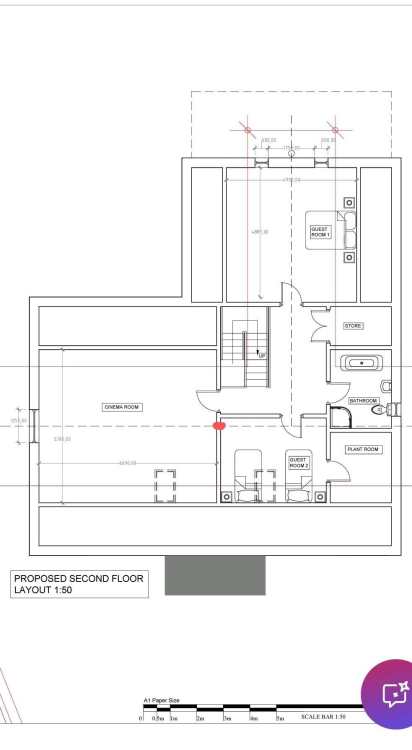

Thankyou 😊 lots of time spent there so really appreciate that. Re the load transfer, the 3rd floor walls around the landing don't sit directly above the 1st floor walls so, is there an issue there transferring the load down? Also, would we need all those internal walls to be solid, load bearing walls? Currently we were intending to do studs on 1st Floor (except stair wall)