-

Posts

1496 -

Joined

-

Last visited

-

Days Won

5

marshian last won the day on June 4 2025

marshian had the most liked content!

Personal Information

-

Location

UK - EA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

marshian's Achievements

Advanced Member (5/5)

410

Reputation

-

Nothing is a permanent solution mainly using the opportunity to see if the behaviour can be ironed out Since 01/01/2026 so 62 Days it's done it's ramp up thing 250 times so as an average 4 times a day Quite tempted to pull the spare MBU from it's storage and see if I can extract the code - I'm 100% sure it's firmware driven

-

It's definitely something like that - only issue is the boiler doesn't have a return temp it does all the management on the flow temp (and possibly the flue temp) Upward temp changes are also a factor - especially when I'm trying to get extended run times. I was toying with getting a clever mate to make me an interface which blunts the changes (basically reads the outside temp sensor but only sends a change in temp to the boiler once an hour)

-

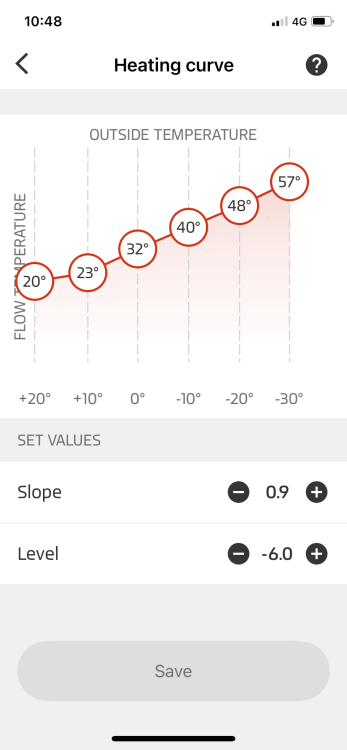

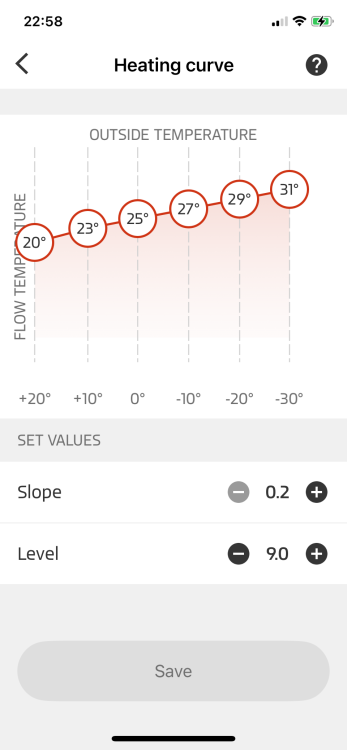

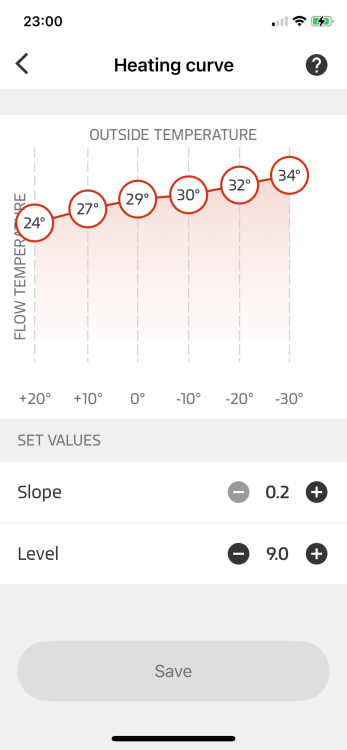

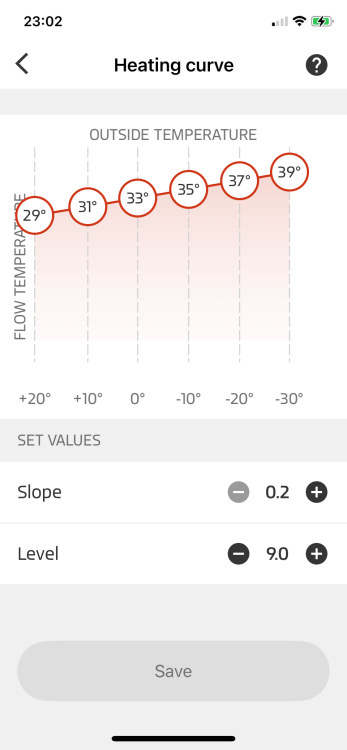

This was my curve above 10 deg this is my curve Room temp target 13 between 0 and 10 room temp target 17 below Zero room temp target 20 it’s basically as a result of flattening the heat curve to a very small slope and then because the room temp offset changes the curve just using that manually to compensate for the outside temp

-

Yeah 100% this is something I see and most people wouldn't notice it It's more common between 4 and 8 deg C - after 10 deg it doesn't really happen It hasn't done it for a couple of days since I've changed my strategy for heating and my current WC curves are to to be frank bloody weird......... I'll post them up later but in summary I now have 3 WC curves, one for below zero, one for zero to 10 deg and one for 10 degs and above and I swap between the curves with the target room temp

-

Well Viessmann technical have washed their hands of the boilers behaviour - their conclusion is that it is normal behaviour for a heat only boiler running weather compensation I'd done a few videos showing the boiler behaviour and shared them with the technical team hoping that this would help to point me in the right direction if it was a set up issue Seeing as they are adamant it's not a boiler issue as such I'll share one here Basically attached a remote microphone to the boiler because the phone itself can't pick up the sound change when it ramps up or down and then filmed the Vicare app on another phone which shows flow temp and modulation level so it's as dull as a dull thing from a content perspective The commentary to go with it is in the description but I'll put it below as well 9.7 Deg Outside Air Temp - Target Flow temp ~25 Deg C Timelines (so you can skip the boring bits) 00:00:20 Boiler Starts (Initial Purge and Burn followed by ramp down) 00:02:12 Boiler at "Minimum modulation" 00:02:47 Running thro the settings (Weather Comp Curve Slope and Level) 00:03:22 thro to 00:15:35 Boiler stable running at min (flow temp slowly rising from initial 27.7 Deg C to 29.2 Deg C) 00:15:37 Boiler modulation increases driving flow temp higher faster 00:17:43 Boiler modulation decreases and then rises again 00:20:18 Boiler modulates back to minimum - flow temps drop to 30.5 Deg C 00:21:45 Boiler shuts down (due to flow temp exceeding target plus 5) 00:21:16 Running thro the settings (Weather Comp Curve Slope and Level)

-

What numbers do I need to size a heat pump?

marshian replied to Selfbuildsarah's topic in New House & Self Build Design

In an attempt to understand my errant boiler behaviour I recently tried to heat a tank of HW with a 16kW boiler when range rated to 4 kWh - it's only a 115 Litre tank to say progress was glacial was an understatement - a bigger tank would definitely be little and often -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

I compare it to bashing your own head repeatedly into a wall It's nice when you stop............. -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

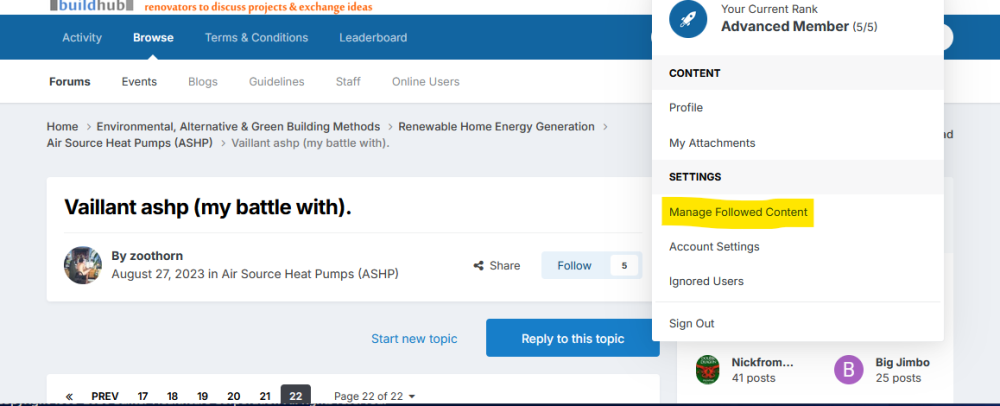

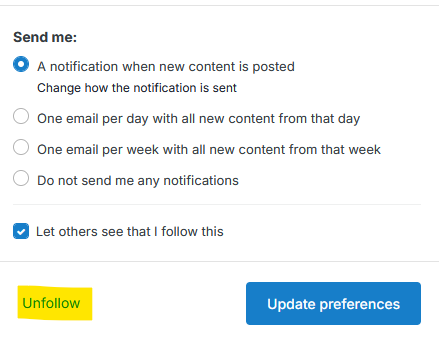

@saveasteading @Nickfromwales@SimonD Alternatively go to your profile Manage followed content Find the "Unfollow" this thread and update preferences -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Ahh I wouldn't mind betting we are of a similar era - Good old Fergal I was gonna say @-rick- bravo for persistence but possible you on a hiding to nothing - good luck -

Our Meaco when on full Laundry mode is 700 watts but it's very effective and wouldn't be without it

-

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

Christ this is hard work - my BH user id is Marshian - You know like from another planet - oh maybe the planet Mars - my better half - Mrs "Alien" (You know like from another planet) I know it's not spelt like that!!!! -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

I'm just saying start low (ish) and work your way up if the house remains cold - I have this irrational fear that you will start high, pronounce the house too hot, can't sleep and turn it off again People tolerances are different - I'm "hot" above 19 - Mrs Alien - different kettle of fish less than 21 is freezing!!!! Well we can start there - what size and type are the rads and what sizes are the rooms - we have enough knowledge on here to start piecing it all together and come up with a reasonable punt I have a gas boiler and I'm running it like an ASHP - CH 24/7 low flow temps (between 25 and 35 Deg C based on weather comp) - when doing HW it raises the flow temp to heat the tank. I could replace it with a 5kW HP tomorrow and know it would work perfectly - this was the point of my rad upgrades and insulation improvements - get HP ready without leaping into it and then finding all my calcs were wrong and I've got a problem. -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

No point saving money with a lower flow temp if the house remains freezing 😉 We don't want @zoothorn cooking though do we 😉 I'd start in the middle (35 Deg) and see where the house settles - increase or decrease accordingly -

Vaillant ashp (my battle with).

marshian replied to zoothorn's topic in Air Source Heat Pumps (ASHP)

What Flow temp you need is simple - the lowest flow temp required to heat the house with the rads you have My house with a gas boiler is between 25 and 35 depending on outside temp............ But I did fit big rads so that I could do low flow temps -

My neighbour had a bloody great conifer in his front garden - far to big for the space - completely blocked the light to his front room. He never pruned it or even topped it. I asked him several times to trim it but he refused. It also meant my side gate and his side gate weren't visible from the road and a low lifer decided he'd gain access to my back garden and break in thro the French doors. As a result I pointed out to him that his house would probably be next and he'd probably need to get a better back gate. shortly after he had it removed but not before the cheeky bugger asked me if I'd go halves on the cost