allthatpebbledash

Members-

Posts

42 -

Joined

-

Last visited

Personal Information

-

Location

West Yorkshire

Recent Profile Visitors

allthatpebbledash's Achievements

Member (3/5)

0

Reputation

-

Thinking about wood flooring and really appreciate the look of the Dinesen products. Even more interesting are the lengths (and widths) of their offerings. The solid planks can go up to 6m and beyond. Their engineered “layers” range can also run to 5m odd. What’s not interesting is the cost of them. Are their alternatives of engineered wood flooring that can span lengths of 5-6m at least to give a seamless floor look of running lengths of wood? I don’t like the idea of a vertical line being broken up by 2 or more pieces. The longest length of any room I have is going to be 6m so I can get away with having a break at one end possibly where it’ll be unnoticeable in the large open area. Every other room will just have a seamless liner look though if 5m lengths can be achieved. Quick google search shows there’s a few wider plank offerings but can’t find any longer than 3m. Any suggestions?

-

Would you say if fitting new windows as part of a renovation, the bathroom windows should be specified without trickle vents? What about a WC only? Would that need a dMEV unit or do without?

-

Velfac click vents vs. others

allthatpebbledash replied to allthatpebbledash's topic in Windows & Glazing

Are you saying they will remain closed a in user wouldn’t remember to keep on top of operating them? I will bear this in mind regarding the dMEV units in wet areas and no trickle vents. Are these the IdealCombi ones? What do they look like from outside, thanks. -

Install a pair of boilers and cylinders

allthatpebbledash replied to allthatpebbledash's topic in Boilers & Hot Water Tanks

My takeaway here is I don’t really need a secondary loop running. I can fit 2 water tanks, servicing each side of the house where water is needed to reduce the arrival time. First in the plant area on ground floor below the master en-suite and adjacent to the kitchen and utility area. Second on the first floor in an airing cupboard next to the 2 family bathrooms and above the ground floor WC. Residual heat would help benefit the airing cupboard too. Plant room tank could be larger than the one needed on first floor too. -

Am I right in thinking the Velfac click vents are the neatest and most discreet type of trickle vents from amongst all of the window suppliers? Or are there others who provide a similarly if not neater solution? If anyone can share images of what their Velfac clickvents look like inside and outside that’ll be helpful. And if you have an alternative window with trickle vents, share those too. My architect is pushing me to go with Velfac but I am also considering windows from GBS/21degrees and IdealCombi.

-

Install a pair of boilers and cylinders

allthatpebbledash replied to allthatpebbledash's topic in Boilers & Hot Water Tanks

Can you elaborate more on what the SY and XW mean? Thanks, not as proficient yet in plumbing. I have read on here where someone has commented the secondary loop system would use quite a bit of electricity and in the end they resulted in turning the system on when guests were around and off during family use to reduce the cost of it. I think it might be possible to locate one of the tanks on the other side of the house, but that would mean losing some space either in the office or cloak area. The latter would be a good bet as residual heat would help keep coats shows boots dry. My architect has mentioned something about making a thermal store using a gas boiler given I don’t want an ASHP. Can you expand on how this works and what its realtime benefits are? Presumably there are some compromises so maybe those too? Thanks. -

Not wanting to jump on to the other post of seeking unlimited hot water for 4 bathrooms, I have a similar question however. Currently at technical planning stages now so trying to gauge possible options. I have a plant room, approx 4.5x5x3m. I have a en-suite bathroom to master bedroom (on FF above plant room) and kitchen/utility is on the same side too of the house as the plant room. I then have 2 more bathrooms (on FF) and a WC (on GF) at the other end of the house. No electric showers. Occupation is 2 adults and 3 children below 10 to begin with. Decade from now, 2 adults and 3 teenagers/young adults. Anticipation is for 2 baths a week and daily showers for 2 adults in the en-suite. In the 2 family bathrooms, anticipating a shower/wash a day from each of the children now and in future. I plan on keeping gas for CH via UFH and DHW. I also have planned a large PV array and battery to be installed. What would be the most efficient way to set this up? From the browsing and reading, does this make much sense. Have 2 cylinders say 300 each, or a single 500/600l? Having 2 would work in this way, one supplies the en-suite and kitchen/utility, and other supplies the family bathrooms and WC. Keeps everyone happy and hot water doesn’t run out when it is needed as adults and children will use at different times, avoids waiting for reheating. If 2 water cylinders, then does it make sense to install a pair of boilers too? Like run a combi for CH and use a system for DHW? Given the solar potential I have, I could divert excess into the cylinders, or use immersion at low price overnight.

-

Maximising a 30kW array

allthatpebbledash replied to allthatpebbledash's topic in Photovoltaics (PV)

This CoP thing is not really indicative of real world scenarios. It’s the only way to win the argument for ASHPs I seem to find online. Unless you’re looking at these technologies from an environmental or carbon emissions perspective, they make very little sense. Most people I know do the following just before they wake up, boiler on for CH, 2-3 hours, then leave for work and turn off. For an ASHP to do this, it can’t. It needs to be on for a lot longer, practically all the time. Hence why it isn’t really cheaper. There’s the fact to have one installed properly and maintained costs a lot too. Whereas for gas, it’s a very competitive landscape to have installs, servicing, repairs etc. This makes sense. Thanks. -

Maximising a 30kW array

allthatpebbledash replied to allthatpebbledash's topic in Photovoltaics (PV)

Thanks for this, pretty informative. Can you share images of how to the sheet metal roof looks with panels fixed on top? -

Maximising a 30kW array

allthatpebbledash replied to allthatpebbledash's topic in Photovoltaics (PV)

Maths is that PV panels are cheaper to cover a roof than tiles. According to Octopus, you don’t need MCS to export now. Not done a deep dive in their T&Cs but have read on another reputable forum it’s a case of fill in a form, pay a small fee with relevant certificates, and you’re good to export. Yes I agree, which is why the size of arrays would be finalised once I get DNO confirmation of what I can export. According to Octopus, they have no export limit on their end either. I get what you’re saying about loads of electric generated, but that’s during the summer when I’ll need an ASHP less. During the winter months, I need it to run most and that’s when I’ll produce less electric myself and have to import at extortion rates. It also makes very little sense unless you have an airtight and well insulated house to get an ASHP running efficiently with an MVHR system in tandem. Summer. Use electric produced or stored in batteries overnight to heat DHW in well insulated cylinder or two. Rest of electric to run majority of appliances. No ASHP needed. Bills low. Winter. Use electric produced or stored in batteries overnight to heat DHW in well insulated cylinder or two. Also run CH. If needed, gas boiler runs on demand to desired temps. No ASHP needed. Bills low. IMO gas will never be more expensive than electric. Ergo, no ASHP needed. Can’t do much about the roof pitches at the back, it was either a small slope at 35 degree angle or a much larger slope at 20 degrees. Thanks. That sounds like the plan of action. Confirm max export. Then based on that size arrays accordingly. Use what I need, charge cars etc, then export at max rate. Import overnight for DHW and batteries, and gas on demand for CH during the colder days. -

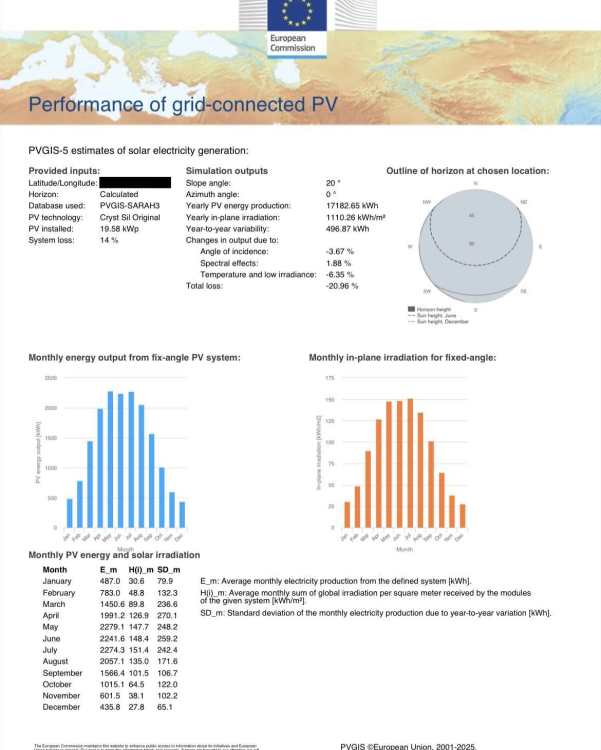

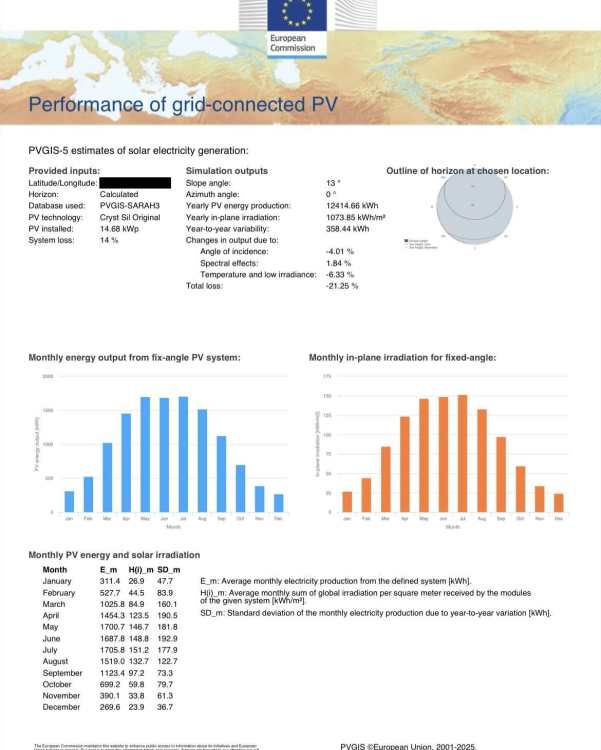

Hello. Part of my house plans is to construct whole new roofs. The back of the house faces almost directly south. I am at the edge of town. No shading anywhere in sight and most likely never will be. The solar potential is huge I’m told and don’t need any micro inverters, and can probably get away with installing one array on a single string reducing cable runs. Winter sees the sun covering the entire rear of the house moving across the horizon nicely left to right. Summer sees the sun rising at front left, moving around to the back and almost directly over the house, all way round to the front right as it starts to set. I’d much rather cover my new roofs in PV panels than tiles. Main roof facing south slope is 20 degrees. Extension roof facing south slope is 12.5 degrees. The other side of the main roof slope facing north is 35 degrees but I intend to keep that panel free for street appearance and it isn’t as large area wise. I can comfortably fit 44 Viridian panels on the main, and 33 Viridian panels on the extension. This is as a starting point using 445W panels, can shop around but I do want an inline system. I have prior DNO approval to have a 55kV 3 phase upgrade of incoming supply. I am with Octopus on a basic tariff, can’t remember which, but told I can change later after I move in to the house as the property is currently vacant pending works so just standing charges at the minute. I have mains gas. I want a system boiler setup to heat via wet UFH and provide DHW. No electric showers, they will run off cylinder/s. I have a dedicated plant room to accommodate everything at ground floor level. Size approx 4x5m. I do not want an ASHP. I want some sort of battery. Can’t decide what size. Most likely won’t go MCS certified route to install due to costs. And due to Octopus giving increased payments non MCS. I will probably install 1 or 2 22kW EV chargers too. No EV yet, but post moving in I plan on upgrading the daily’s. I’ve attached my PVGIS data, but I don’t know what to make of it. I’m being advised the DNO will most likely allow a higher export limit beyond the 11.04kW of 3 phase I believe. I’m being told I should oversize my water cylinder, dump excess solar into that. Forget batteries. Im also being told I should simply export everything that’s not being used, and only have a small battery to keep power to run for 24 hours usage. It’s a waste to go any bigger. I’m also advised I should forget getting 2 arrays, and focus on the main larger one only. How would you make the most of this situation?

-

It’s possible I may need someone to model my existing house, the proposed plans, and run through scenarios of what various levels of improvements would result? I don’t want to stick 100mm EPS to the outside as a blanket if say 140mm would give me much better comfort for not much extra cost. Are there any services people can recommended who help with this?

-

70s Bungalow - Possible Gut It - Insulation

allthatpebbledash replied to Rogersp's topic in Heat Insulation

That is very convincing. Say if you had a poorly filled mineral wool cavity, and it was going to be easily vacuumed out, this would nicely in refilling it. Could you use these in newly built walls too? What width cavity would be needed if built using blockwork to reach min building reg u values? What did you end up doing OP? -

When is a large renovation a new build?

allthatpebbledash replied to peekay's topic in Planning Permission

Understandably this makes sense. Was there a possibility in which you would’ve gone about it as the following; since you having planning approval for the renovation, so whilst works were ongoing, submitted a concurrent application with the same drawing sets (more or less) but with a full application for demolition and rebuild? This way you would’ve continued to make progress on site, works staged so that you would avoid doubling back on the remaining walls till after a decision was made? This is exactly my thought process right now. The cash flow aspect is critical. Given the cost of a new planning application which is circa £600 with my LA, the saving of a further 5k per every £100k on the works does sound attractive. If the total cost for instance runs up to £250k, that’s a sum of £12.5k which can fit out 2-3 bathrooms. I think? But I can’t help think if all the walls came down, would building control allow existing foundations to be used? Would they allow the cavity’s to remain the same width, or dictate new wider foundations? Would they stipulate the wall insulation value be improved if allowed to keep the foundation and cavity the same? In my case, I would be having 2 external walls left standing hence the line of questioning. After much reading on here and elsewhere, I think the saving of £12.5k for instance could easily be sunk in the above added works easily. New foundations and extra insulation. Unless someone more clued on could educate me on this. I am pretty conflicted. On the one hand I’d end up with a better insulated house and build up without errors of the previous construction, but at the same time, how much thermal performance can be made to make it worth it? If you can shed more light on this (privately via DM if you have to), what do you mean by getting away with it? Would the remaining standing walls “accidentally meet steel” therefore need to be taken down for safety and rebuilt? How would the building inspector react to this? I’m sure this kind of stuff happens all the time. -

When is a large renovation a new build?

allthatpebbledash replied to peekay's topic in Planning Permission

Bringing this back up, can you point me in direction of this person? I want to read through what happened and the fallout as a result, thanks. What did you end up doing then? I find myself in a very similar position.