bmj1

Members-

Posts

247 -

Joined

-

Last visited

-

Days Won

1

bmj1 last won the day on March 20

bmj1 had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

bmj1's Achievements

Regular Member (4/5)

72

Reputation

-

Deciding to say "no" to a self build opportunity

bmj1 replied to maison d'etre's topic in General Self Build & DIY Discussion

You need a more detailed budget for your project, because factors can vary significantly site to site. It is also massively dependant on your spec and level of involvement. Lastly, don't forget professional fees -

Deciding to say "no" to a self build opportunity

bmj1 replied to maison d'etre's topic in General Self Build & DIY Discussion

It's going to cost a lot more than half a million quid for a 285 sq meter house to a high spec. And the utilities are really gouging on pricing works these days. This might not be the typical buildhub reply, but it sounds like one to let go. -

We compromised: Flemish on the front and rear elevations, stretcher on the side. On ours, the side elevations aren't so visible, due to close proximity to the neighbours. I'm happy we did this and spent the extra

-

I can't imagine anybody will be putting 100mm of phenolic insulation around their A/C ductwork...! It will surely be Kooltherm... But, it could be K107 which has a reduced compressive strength - so that's potentially something to consider

-

I'm not sure the phenolic stuff could be anything else, i.e. it couldn't be the cavity wall stuff as not the same dimensions. I called them by phone and asked if it was equivalent to the k103... My experience was the stuff was perfect, albeit the odd cosmetic damage. Under the screed, it wasn't going to make any difference.

-

I bought the phenolic stuff from seconds and co. Was equivalent to k103. Great stuff. Great price.

-

Hi all, Looking to tie a portico to my house. Foundations are done for the portico and tied to the house foundations. I guess my only option at this late stage is chemical fixing the stone portico to the brickwork. How do I calculate the requested frequency and thickness of the fixings? Thank you in advance

-

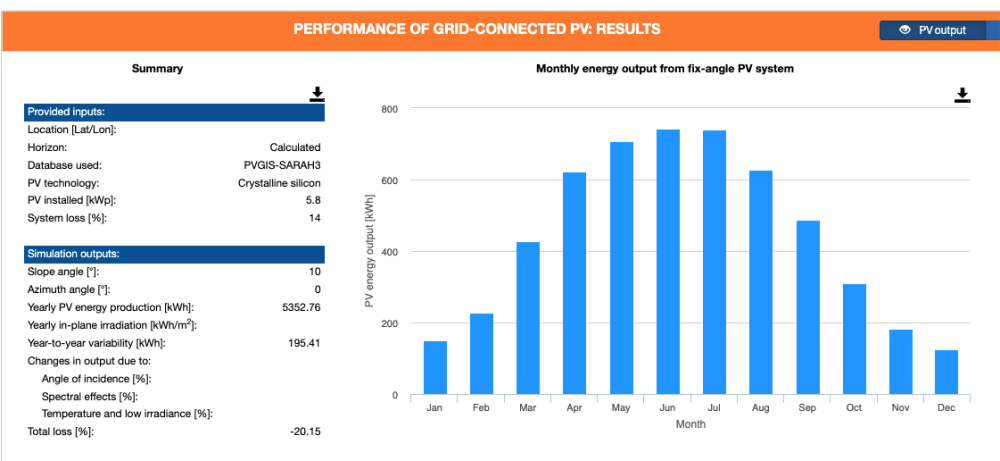

1) I've got 3-phase. 2) Corrected chart for a 5.8Kw array: 3) I now understand that it's ideal to undersize the inverter by ~20% in the UK, so if sizing a 5.8Kw array, then a 5Kw inverter is about perfect. 4) Right now a bunch of energy companies are paying 15p/Kwh for SEG in London. So I'm think it makes sense to skip the battery altogether for now (but have a hybrid inverter). Anything I don't use, I'll export, and the net/net is it reduces my energy cost from 22p/Kwh -> 7p/Kwh (22p-15p). As/when battery prices come down, or SEG prices drop, then it makes sense to bite the bullet and get a battery. Thoughts ?

-

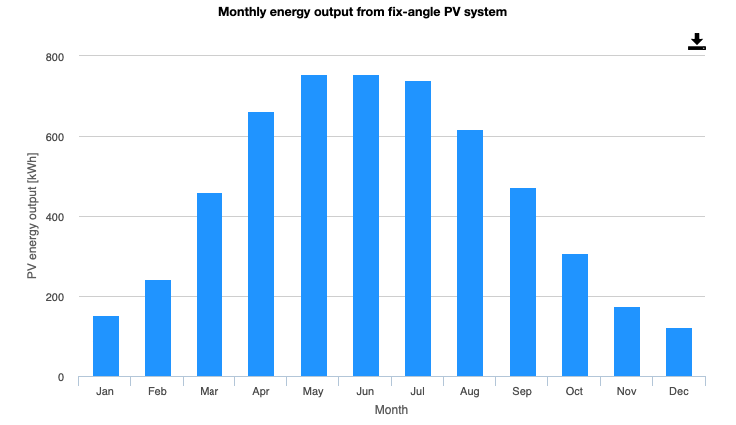

Thanks @SteamyTea - here is my first cut with the 5.8Kwh array. As you have pointed out, there is huge variability. In the month of July I'd basically generate my daily usage... (739kwh) - or 24kwh per day. So with this in mind - how big a battery would be optimal ?

-

Ok - I guess I can start with the PV - see what I'm generating - and then size the battery and add that in - if it makes sense to do so ? I'm not clear how I size the inverter though ? E.g. for the 5100Kwh system above, what size inverter would be appropriate ?

-

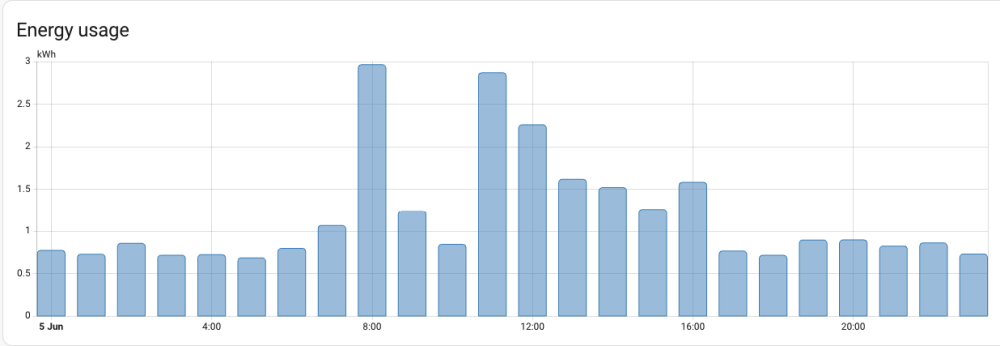

Hi all, Just finished my build, my typical daily usage looks like this: (28kwh total in 24h) I'd like to install solar PV (and perhaps a battery), objective is to maximise ROI. I've got a flat roof with room for: 1) LONGi Solar Hi-MO X6 Explorer 535w Black Frame Solar PV Module - LR5-66HTH-535M - x8 => 4,280Kw system Or alternatively: 2) Sunpower SPR-P6-400-BLK (400w) - x10 => 4,000Kw system Or alternatively: 3) Aiko Neostar 2S 510W N-Type ABC, 60 Cell, All Black Solar Panel (510W) - x10 => 5,100Kw system Or alternatively: 4) JA Solar JAM66D42-580/MB - x10 => 5,800Kw system I'm in London, so I understand a 5.1Kw system can be expected to generated ~10Kwh of electricity per day (so roughly 36% of my daily usage). Spread over 8 hours of sunlight, that's 1.25Kwh of energy per hour. With this in mind - I'm tempted to skip the battery altogether. So I just need: PV panels (and mounts) 3-phase inverter (would a "Huawei SUN2000-8KTL 8KW 3 Phase Solar PV Inverter dual MPPT" be okay ?) If I understand correctly, if I'm generating 10Kwh of electricity per day, then that is 3,650 per annum, so I'm saving ~£900 per annum at current prices. If I spend £2.5k on the panels and mounting kit, another £500 on the inverter, £250-£500 on a sparky for 1-2 days to wire it up, I'm looking at pay back in 4 years. The other benefit of avoiding the battery is it's in a small plant area, and I've got my networking kit in there, and I don't really want to heat it up and need to put in A/C or some more active ventillation. Key Questions: 1) How do I know if the panels are compatible with the inverter I've proposed above ? 2) Is an 8KW inverter sufficient for 5.1Kw of panels 3) Any other thoughts/suggestions ?

-

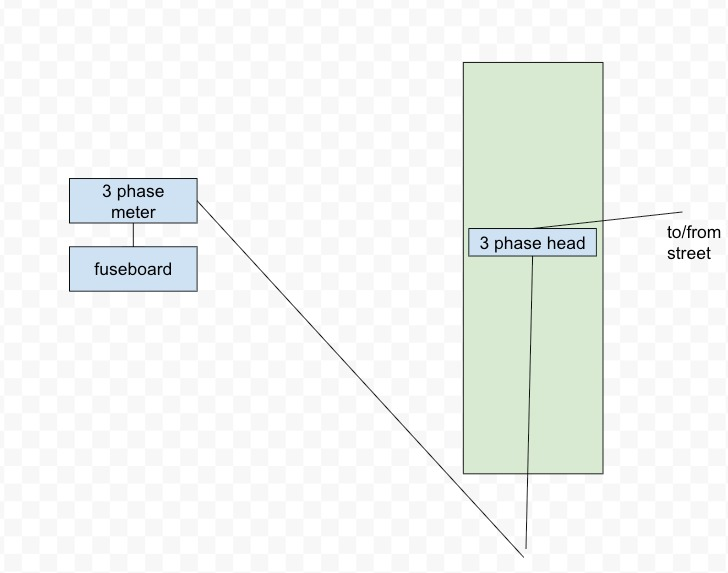

Positioning of electricity meter outside by head, or inside by plant

bmj1 replied to bmj1's topic in Electrics - Other

Thanks both: 1. PV into fuseboard would be easiest, so no benefit. 2. EV charger is actually located right by the cabinet with the head and meter, so moving the meter will be a pain (would need to run another thick armoured cable) Sounds like the best thing to do is keep them as they are ! Thank you ! -

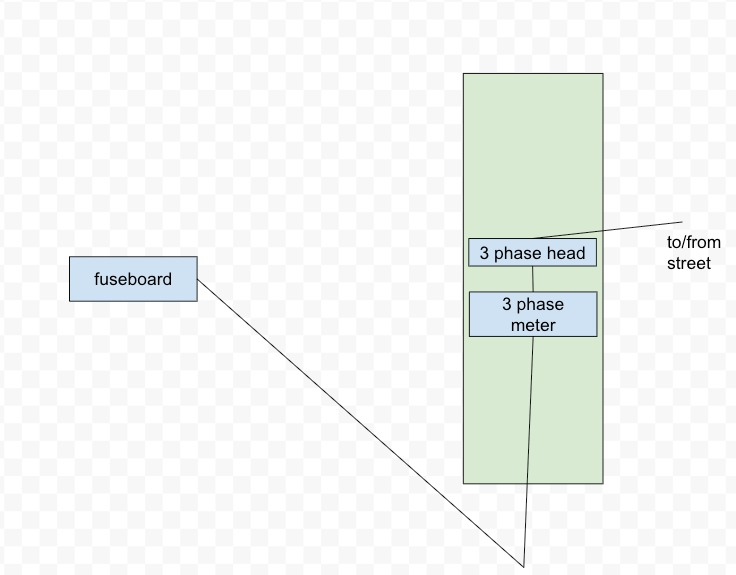

Hi all - my current wiring is like this. All the plant is by the fuseboard. Is there any advantage at all to moving the 3 phase meter to be located by the fuseboard and plant ? (like the below) E.g. does this help if I start putting PV + batteries in, or exporting to grid, or anything else ? Or does it make no difference at all ?

-

No they aren't, and they add up ! ebay is really your friend, if you aren't in a rush, set up some searches and let it come to you

-

Amp: I went for a Denon amp, picked up Denon AVC-X6500H for £850 on ebay Speakers: I also did Monitor Audio, picked up a bunch of the Monitor Audio CP-CT380 in-ceiling speakers end of life, then mounted an SB-4 Soundbar at the front because I didn't want to compromise on the LCR channels with in-ceiling speakers Subwoofer: I did a SVS SB-1000 Pro Subwoofer - picked one up for £350 on ebay - ended up pairing it with the SVS Soundpath triband adapter for wireless signal as I hadn't planned properly for the subwoofer placement & wiring up front I also made use of the Dolby guides referenced above. Good luck ! And don't be afraid to buy some of the kit used if you get a decent discount