HughF

Members-

Posts

1363 -

Joined

-

Last visited

Everything posted by HughF

-

Looks like the party is over....

HughF replied to Beelbeebub's topic in Air Source Heat Pumps (ASHP)

Remove the stupid planning restrictions around outdoor condensers and just pivot to air-air for domestic heating - much cheaper, easier to fit, f-gas industry is already existing and the units are already ‘smart’ out of the box which apparently people want these days. Oh, and they cool out the box. -

Looks like the party is over....

HughF replied to Beelbeebub's topic in Air Source Heat Pumps (ASHP)

Even if we do, it’s far more efficient to burn it in a CCGT, transmit the energy to the home as electricity, then run a heat pump with that electricity than it is to pipe the gas and then burn it in the home. Breakeven point for efficiency is a scop of 2.8 iirc. -

Looks like the party is over....

HughF replied to Beelbeebub's topic in Air Source Heat Pumps (ASHP)

We could use the same logic with taxi drivers - Taxi drivers don’t buy premium cars. They buy cars that give them minimum cost of ownership whilst doing the job they need to do. The big house builders fit the cheapest thing that does the job. Generic 70mm uPVC, minimum cavity insulation, ideal logic combo boilers. I’m not talking about the people who frequent this forum and build ‘decent houses’ - I’m talking the big national house builders where it’s all about maximising profit whilst just about complying with the minimum standard set by BR. They’d fit electric panel rads because they’re dirt cheap. -

Looks like the party is over....

HughF replied to Beelbeebub's topic in Air Source Heat Pumps (ASHP)

If you didn’t mandate it, the house builders would just fit electric panel rads as they’re cheaper. House builders always aim for the cheapest option. -

Looks like the party is over....

HughF replied to Beelbeebub's topic in Air Source Heat Pumps (ASHP)

And that is how it should be done…. -

Another 'Cool Energy' heatpumps thread

HughF replied to HughF's topic in Air Source Heat Pumps (ASHP)

That’s a good place for it. A lot of other manufacturers already have flow temperature sensors installed internally so even when you do run them with a buffer/llh/plate/whatever you don’t need for an extra temp sensor. SPRSUN doesn’t have an internal sensor so the buffer probe needs to go somewhere. -

Another 'Cool Energy' heatpumps thread

HughF replied to HughF's topic in Air Source Heat Pumps (ASHP)

Pretty much, yep…. the new grant r290 hydraulic schematic appears to be properly designed (no buffer, no trv heads, single zone)… most of the others I’ve seen are just standard buffer + secondary pump. Especially Chinese ones. -

Another 'Cool Energy' heatpumps thread

HughF replied to HughF's topic in Air Source Heat Pumps (ASHP)

Standard SPRSUN design choice - commonly used in China where electricity is cheap and they’re competing against direct electric heat so any cop is a good cop. I see it in 75% of the Vaillant schematics too, which isn’t very good I just taped my buffer probe to the 22mm that feeds the rads and covered it in insulation. -

Another 'Cool Energy' heatpumps thread

HughF replied to HughF's topic in Air Source Heat Pumps (ASHP)

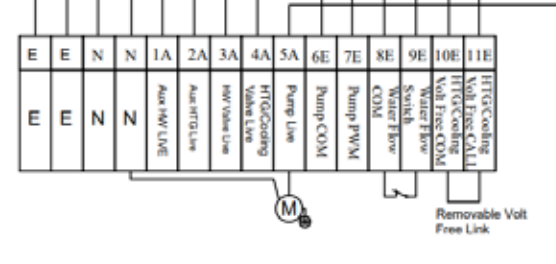

Got it... yeah that's the exact same terminal strip pinouts as the older invertech units, with the exception that the invertech has an internal pump already wired in. It should 'just work'... -

Another 'Cool Energy' heatpumps thread

HughF replied to HughF's topic in Air Source Heat Pumps (ASHP)

Looks like the primary pump is inside the unit... What do you need an external pump for, and where did you intend to get the PWM signal from as there's no terminal for this broken out on the main PCB. -

Another 'Cool Energy' heatpumps thread

HughF replied to HughF's topic in Air Source Heat Pumps (ASHP)

Do you have the manual for the ET-10, I can't find it on the CE website... -

As I've been digesting the Vaillant schematics for someone else, attached is the one that will give you what you asked for. Arotherm plus RADS + UFH no buffer.pdf

-

Same here. Weather comp, nest as a glorified on/off switch

-

-

I still stand by my ‘nah, don’t bother’ statement…

-

Take the TRV heads off, turn the room stat right up. Leave it for a day.

-

This is exactly what I'd be doing... I know it's not what you asked for, but it's the right way to run the system for maximum efficiency.

-

You've got a couple of options: 1. Fit a dumb pumped manifold to the UFH, hydraulically decoupled from the radiator flow and return using close-coupled T's (this is what I use). Then increase the flow temp so the upstairs rads feel warm. 2. Fit a Vaillant mixing station to provide a mixed circuit independent of the radiators. 3. Upsize the rads in the upstairs rooms to suit the fixed flow temp of the UFH. In relation to option 3, do you know if the rads were sized for 35 degree flow?

-

What brand of heat pump?

-

It could be that my book of schematics is out of date, but I did find it annoying and slightly weird that the standard single zone, no buffer, single pump schematic was on page 75 of 99... Just looking at the Grant handbook now, nice to see such simple and well explained schematics.

-

Good luck getting that from any of the big heat pump installers.. Even the Vaillant big-book-of-schematics doesn't show any electronically mixed circuits, and Vaillant are often considered a premium product.

-

You got a warranty with your CE heatpump?

-

post pictures of your UFH manifold, please.

-

Another 'Cool Energy' heatpumps thread

HughF replied to HughF's topic in Air Source Heat Pumps (ASHP)

If you’re using a ce-ivt 9 or 12evi then the knockout in the casing will take a 25mm flexicon adapter. I used a Belden multi core as I don’t like working with non-stranded cat5e. I used this for the call for heat, temp sensors and the carel pLAN wiring. -

Found the schematic book for the + which I assume is the same. Slightly sad that you need to go to page 75 out of 99 to find the correct hydraulic schematic for 90% of users (direct, no buffer, single zone)