Rishard

Members-

Posts

176 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Rishard's Achievements

Regular Member (4/5)

29

Reputation

-

Also interested in this micro cement flooring. Did you go with it in the end?

-

Are you able to share a cost for this? Would love to know. 🙏

-

It is a straight run, apart from a 45° where it joins into the stack. I’m happy to make it the designated site bog while the build progresses. That should put it through its paces. I did think about having a high level traditional cistern. Would this add any extra umphh to it? the storage solution is also a good idea. I’ve done plenty of boxes out skirtingboard plinths in the past for customers. Feels like a bit of an after thought, a cupboard sounds more intentional.

-

If I was to run the en-suite w/c the full distance it would need to travel 5.6m to get to the stack. I’ve got 50mm at the very most for the fall. Do you think that’s possible? Would be great if it was… I’ll have a building inspector but if it’s the same guy, I doubt they will give it a seconds glance. More for my own piece of mind. He didn’t care a dot about the tons of mesh Il lapped to specific distances and tied beautifully all to the spec of my engineer. More interested in talking about how crap the company he works for is. I’ll try some of that banding and mating. Looks the business.

-

I’m going for 12.5mm per m. This works to the original plan as sadly I only have 50mm adjustment within the web of the joists. 110mm pipe inbetween the 160mm webs. Based on this lack of fall to move the en-suite w/c to the new location using the floor void to get the fall I may have to settle with its original location. Alternative option would be to exit the w/c waste out the wall and create a new stack to serve this externally on the house. Not a fan of this. or box in above floor level in the en-suite . Also not much of a fan of this. Should have gone for the larger joists… ah well. Maybe next time.

-

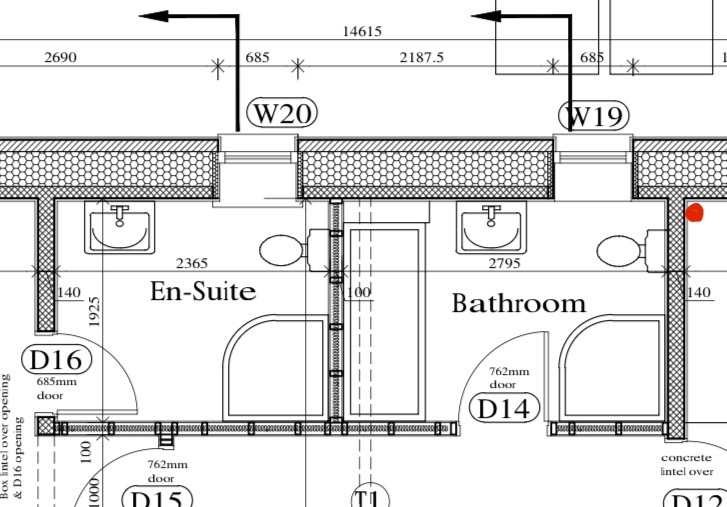

Ok that makes sense. I think I’ll try dog leg the stack so it comes up in the bathroom using 2 x 45° bends. Just enough offset to get through a 140mm block wall and come up on the otherside. It’s doesn’t look too upsetting. My en-suite w/c is 2.8m from the stack so I can just get the fall within my joist webs. Do you think if I wanted to move my w/c to where the basin Is in the en-suite. Could I do a stub stack in the corner where the w/c is currently located and gain the fall above floor level in boxing? Because of where the joist webs are my 110mm pipe is about 200mm from the wall. A swept bend might be needed if I was to do the stub stack option. I see in the regs that it should be avoided where possible but can be used if large radius bends or 2x45° are used. Would be using an aav.

-

Great. This makes much more sense than trying to run multiple individual wastes back to the stack. I want them all to be ran in the floor void to keep the rooms as clear as possible. Would I be right in thinking all these bends / connections want to be solvent welded connections?

-

I agree, main soil stack can be dog legged to come up in the bathroom which makes sense. Are you saying the 2 toilets should have their own 110mm run rather than joining together before joining the stack. Once the en-suite toilet waste is in the joists, is it ok to join on to this run with say the shower waste? Would I use a strap boss onto the 110 or is there a better method?

-

Hello, just scouring the web / forum for similar ideas relating to first floor waste runs. I’m trying to work out the best way to route my waste pipes back to my stack. Is it best to try group the en-suite shower/basin/w/c into one 110mm pipe and back to the stack, or keep w/c separate from the basin and shower? From my research, these could step up to 50mm pipe from the basin/shower and back to the stack. OR Should I be trying to group say the w/c from the en-suite and the bathroom on the same 110mm run to the stack? Keeping the en-suite basin / shower on one 50mm run and do the same for the bathroom? I have posijoists which I can route most of these runs in. The w/c near my stack could go through the wall if beneficial. I’d also take some advice on good way to fix all this pipework to the posi joists. I thought about using some rips of ply to use as a side wall which I could clip / fix pipes to (on a fall) but if there are any other good bracket fixings people have used which would take up less space I’d be interested to know. Has anyone used much dampening on the larger soil pipes to reduce noise? Just a thought as the stack is currently coming up in the corner of a bedroom. This could be adjusted to come up in the bathroom if it makes more sense. Thanks for any insights. Stack highlighted red

-

Aluminium Gutters / Soffits - Who to use?

Rishard replied to boxrick's topic in Roofing, Tiling & Slating

@Russell griffiths what roof system / covering is that? Looks brilliant. -

Closing cavity at the top for blown beads

Rishard replied to MortarThePoint's topic in Heat Insulation

I was aware of the fire issue in clear cavities. It’s mostly the moisture issue I was concerned with, if it is a concern at all? -

Closing cavity at the top for blown beads

Rishard replied to MortarThePoint's topic in Heat Insulation

Other than preventing air movement and in some cases blown beads, is there any other reason to close of the cavity where it connects with the roof insulation? I know mineral wool is none combustible so fire spreading isn’t an issue. Is moisture travelling from the cavity wall upwards towards the roof insulation a concern at all? I’m detailing my wall junctions similar to @Mr Blobby with mineral wool. Below my rafters I will have my vcl which prevents moisture moving into the roof. I hadn’t thought about moisture moving from the cavity at eaves and the gables into the roof insulation. -

There is a ridge board above the glue lam which the rafters are all fixed to so there are no holes in the dpc. It’s also stuck down with airtightness silicone. Would have used a ‘smart’ membrane similar to the vcl which I’ll be using but didn’t have any to hand. Felt the dpc would be better than a roofing membrane out of the 2 available materials to hand.

-

It’s dpc. It will tape into my vapour control layer once the osb is attached to the ceiling. I was just going to tape the vcl to the beam but figured this would be a lot easier.

-

My longest ridge beam is only 6m. I’ve used glue lam throughout as I love the look of it. I’m actually lifting them up tomorrow so I’ll get some pictures. I also built a gluelam truss just to give a bit of a wow factor as it’s above the main enterance at full height from ground floor to the ridge. I actually joined a couple of glue lams, they join on a masonry wall. That beam is now 10m long. My supplier could supply up to 15m I think but I would struggle to lift my beam in at 10m. My engineer calculated my beams and I basically doubled the height mainly for aesthetics. I think I could have gone deeper still. Here are a few pics: