The Thermal Design – Part I

Janet and I want an energy efficient house, but what does that mean in practice? The whole concept is still largely rejected by the UK building industry. In our initial research, we either found books like the House Builders Bible which are good but superficial introductions on the concepts but without serious detail or at the other extreme academic papers on micro details. There is precious little in between, and to be honest we have found far more gems of knowledge in this site. All my experience and intuition concerns living in a traditionally built house. An energy-efficient house is just a different beast entirely, so I discarded my intuition and put my trust in the physics, maths and engineering. Likewise, we only considered the views and recommendations of those who have actually lived in this type of house.

One of the first things that I did was to build up my own version of Jeremy Harris's Heat Loss Calculator.xls (which he first developed on this GBF topic). I plugged in the numbers for our own house design, but in reality there are only a few parameters derived directly from the house geometry that drive this calculation (my numbers are in brackets):

- The internal footprint of the slab (71m²)

- The internal surface area of the external walls, less windows (179m²)

- The internal surface area of the roof, less roof windows (93m²)

- The area of windows (23m²)

- The total volume of the internal living spaces (419 m³).

Each of these is multiplied by a factor derived from the design to give a heat loss per °C: a U value in the case of the first four. The last is more complex in that I had to build up a composite heat-loss based on the rate of air exchange, its unit mass and specific heat, and importantly the recovery efficiency of the MVHR.

For a typical winter external temperature of 4°c and an internal 21°c, this gives a delta of 17°c for fabric heat losses. The slab delta is somewhat different in that the ground temperature under slab is far more constant – say 10°c at the centre of the slab and maybe 6°c at the edges in the winter raising to 15°c in the summer. Plugging in our current design values (from our frame supplier, MBC) gives the following heat loses for a typical January day:

- Slab: 97 W (9%) – 71 m² x 0.105 W/m²/K x 13°

- Walls: 364 W (32%) – 179 m² x 0.120 W/m²/K x 17°

- Roof: 171 W (15%) – 93 m² x 0.105 W/m²/K x 17°

- Windows: 313 W (28%) – 23 m² x 0.800 W/m²/K x 17°

- Air change: 180 W (16%) – 419 m³ x 0.025 W/m³/K x 17°

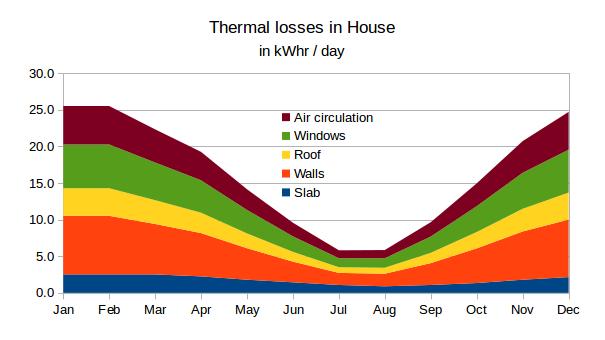

That's 1.1 kW in total, or as I sometimes say to friends, the whole house could be heated by a single 1-bar fire. Clearly this heat loss varies according to season, so if I plug in an overall temperature profile for my location, I then get the following daily heat losses in kWhr :

The house is reasonably balanced as a system: no single component dominates the heat losses. However, this wouldn't be the case if we dropped the heat recovery element of the MVHR, for example, as this would increase the air change heat losses by roughly 5x, becoming the majority of total heat loss. This is why the inclusion of MVHR is such an important component of energy-efficient design.

If we look at the risks and sensitivities in this sort of calculation, then they broadly fall into two categories: failures in airtightness and thermal bridging at boundaries. (Googling these highlighted terms will give background explanations of what these are). All internal surfaces in a properly implemented energy-efficient house are within a few degrees of the internal temperature, which also means that there are no internal condensation surfaces. A serious consequence of thermal bridging is that surface temperatures can drop significantly at the bridges below the internal dew-point, causing surface condensation.

Failures can occur with sloppy design or poor attention to detail during construction, so I believe that it is a lot more important to find a frame manufacturer / assembler who gives us confidence that these issues will be effectively addressed (as failures here could cost kilowatts of heat loss or mouldy surfaces) rather than whether the walls have a nominal U value of 0.12 or 0.14 (which varies the total heat loss by roughly 60W at most). However, this heat calculation isn't the whole story:

- We typically have three occupants in the house and being alive we radiate heat – roughly 300-400W between the three of us.

- The 23m² of windows can let in up to 1 kW/m² incident energy in direct sunlight.

- Our average daily electricity usage in our current house is 16 kWhr / day. We will cut this a bit in the new house, but this is a combination of lighting, DHW and running electrical equipment – fridge, washing machine and my live-in son's Gaming PC + Xbox.

Apart from some of the DHW used (which literally goes down the plug hole), all of this energy eventually ends up as waste heat within the living environment, and therefore adds to the general heat budget – that's roughly 1kW plus the solar gain. This 24 kWhr/day or more means that we will often have a heat excess within the house. On the other hand clearly these temperatures are profile averages and there will be periods where the temperatures will be lower, and below zero for extended periods. However, even a doubling of the temperature deltas only give a running heat loss of approximately 2 kW. My overall conclusions are:

- Our overall heat budget will be in near equilibrium for large parts of the year.

- At most the sustain heat input requirement will be of the order of 2kW peak.

- We need to manage heat excess efficiently and automatically up to say 2kW.

I want to expand on this last "automatically" point: in our current farmhouse with its 2ft thick walls, the house environment is sufficiently stable for a large part of the summer and autumn that we turn off all heating and leave windows ajar all day, relying on natural ventilation. We feel that warmer weather should result in periods where we can do the same in our new energy-efficient house. However, we don't want to be forced into the situation where we have to dash around the house a few times a day opening and closing curtains, blinds and windows just to keep the house at a stable temperature: in general, the house should look after itself.

This imbalance (or a lot more on sunny days with the solar gain through windows) is a material issue and to put this in perspective consider:

- The mass of the liveable airspace in the house is some 500Kg with a heat capacity of just over 0.5 mJ/K or 0.14 kWh/K.

- The specific heat of the slab is less than that of air (0.75 kJ/kg K), but the mass of over 7m³ of slab concrete is significantly more (16.4 tonne) giving a heat capacity of 3.42 kWh/K and the plaster board, etc. within the walls adds perhaps another 10% to this capacity.

- There are various equations for the heat transfer between the slab and the air above it but a good ballpark is 10 W/m²/K – that is roughly 0.7 kW/K for the entire slab.

The slab and the other fabric which sit within the thermal envelope of the house has over 20 times the heat capacity of the air inside the house. So if we were to heat the input air from the MVHR to 10°C above room temperature, this will transfer about 0.7 kWh heat into airspace of the house in one hour at 0.5 ACH – the same as running the slab at 1°C above room temperature. In extremes we can easily lift the slab temperature say 5°c to increase the heating slab effect five-fold, but at another 2x the air heating route will start to be problematic with noticeable effects on air quality and background noise if we increase the ACH to do so..

Our initial intention was to use an integrated MVHR + ASHP(Genvax), but there was always a concern that this would be inadequate to cope with extreme cold spells, so we planned to use a supplementary closed wood burner. However the problem with any stove is the minimum output (typically 2-3 kW) which is simply far too much for the living room to cope with. So we abandoned that idea: there's no point in installing a stove that you will never use in practice.

This analysis plus Jeremy's reasoned argument also convinced us that an active UFH slab was the way to go, for the following reasons:

- It's a relatively low cost option.

- It addresses a saleability risk: "I want to fit a gas boiler"

- With a suitable ASHP it enables active cooling as well as active heating.

- In circulation mode it is extremely effective at distributing the heat throughout the entire slab from any hot spots caused by direct sunshine through the windows.

With this reasoning the advantages of a combined ASHP+MVHR just seemed to dissolve, and we've now decided to abandon the Genvax in favour of a standard passive MVHR system. We have still to chose the ASHP, but we are looking at a low power (say ~5 kW) monoblock inverter-based design alone the lines of Jeremy's active slab approach, but more on this in later posts as I finalise details. We also need to think about the vertical temperature gradients in the house (our hallway / landing rises through all three floors into the loft space). Hence this is only part I of the thermal design. ![]()

-

2

2

4 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now