Search the Community

Showing results for tags 'process'.

-

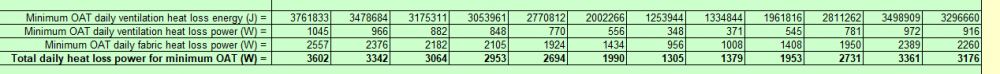

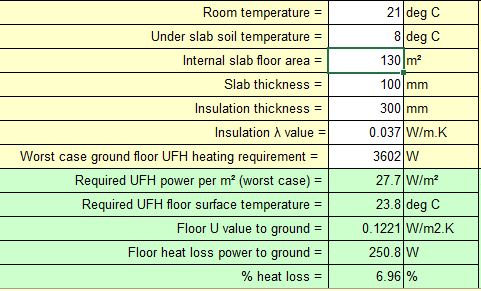

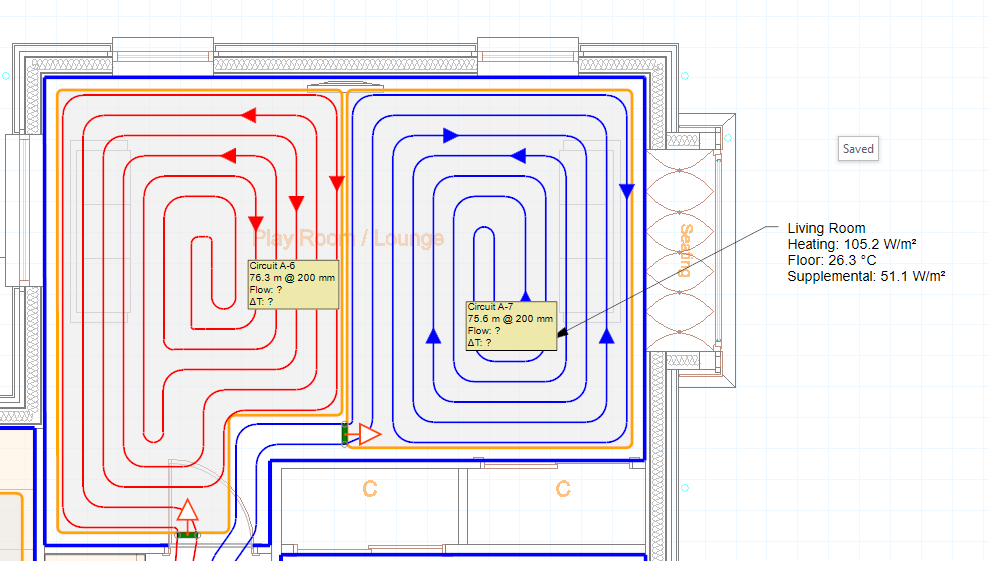

I've read various threads and views and back and forth and done some calculations based on information I have found here and of course from the very helpful spreadsheets provided by our friend @Jeremy Harris. I had pretty much decided ages ago I would get an 8.5kW Ecodan, which might go up to an 11.2kW ecodan unit. However I have not really advanced it beyond basic assumptions, what others done and some quick back of the fag packet calcs. I'm about to start foundations shortly hence, need to firm up on the UFH design for the in slab pipework and would appreciate some sense checking/ a wee nod that it seems ok. Build is SIPS with Kore insulated foundation, aiming for high levels of airtightness but not near PH (basically as best as I can get it without major hassle), Vent Axia Sentinel MVHR. ASHP which does UFH and DHW (UVC 3-400L tank). Secondary heat source of Log burner (I'm aware it's overkill likely - but I have 2 acres of woods, vaulted ceiling and need a backup in the event power ever went out). I would like to map out the steps in layman's terms to ensure they are right and I have followed it correctly from what I have read, then hopefully the thread can then be followed by others. Step 1 - Heat loss calculation: So I completed the heat loss calculator - see attached. I have a few checks to do on areas and might make minor adjustments but near as dammit it's close enough. I have added the OAT values for my local area (West Scotland, south of Glasgow) from the MET office. Now do I basically just use the 'Total daily heat loss power for average OAT (W)' value to find the maximum based on historical data and that defines the minimum amount of heating system required such below: which seems 3.6kW heat loss for January. The simply - I select a heating system which can supply this amount of heat as a minimum (ignore losses for now). So just simply selecting an 8.5kW unit would do the job easy? Step 2 - UFH design So Having found out the maximum heat loss above (3602W) then we can just plug this into the Heat loss and UFH calculator, which I have also attached. And provides the following output. So essentially, going on bare minimum I would need an UFH system which provides 27.7W/m^2 , based on 130m^2 of floor - so essentially if I don't use some slab area then I need to compensate and adjust the calc. Step 3 - UFH loop spacing So I know the total heat loss, I know how much heat input I have to supply per m^2 if I cover the whole area of 130m^2. So I get loopcad, then draw the circuits. Aiming for counter flow circuits as they provide the best option for even heat distribution, keeping circuits less than 100m in length. Now this is where I get a little lost, I have a figure of 27.7W/m^2 for the whole area to get my required heat input, however how do I correlate that with loopcad and also deciding what my spacing should be?! I have seen @PeterW mention quite a few times about the the spacing had to be adjusted but I am struggling to find the route here to confirm easily what it should be. My loopcad drawing (I've attached my current draft) showing for example 105W/m^2 in my living room, but I'm not sure how this should read in relation to my calculated figure. I'm pretty sure I'll need 200mm centres, but I'd like to ensure that was right. I've some adjustments to make to my circuits, but it's not far away. I was finding that the auto generate function for pipework isn't ideal but it works ok. The garage can be ignored - I ma installing pipework in there pre-empting possible future conversion of that area and hence pipe is cheap, so why not add it now. The manifold will go below the stairs - seems to make sense to me, I have a plant room directly adjacent and was going to put it in there but seemed better to get it out of there as I will have lots of ducts and this would clutter that up. Is it ok to run underneath the stairs? I assume I just have to tell the Joiners not to fit the stairs to the floor with big screws?! Step 4 - Zones I am only having downstairs heating, so it is a single manifold. I would prefer as few zones as possible, but a single zone wont work. I was thinking I can have two /possibly three. Zone 1 - Main family room area Zone 2 - Everywhere else excluding shower room and garage Zone 3 - Shower room Zone 4 - Garage (permanently isolated at the moment. I assume you can have multiple zones on a manifold, and can just split them up by using salus actuators?. So a single thermostat for family room can control three loops (each with an acutator) in that room? and so forth?. It's a long post , and actually I wasn't going to talk about zones but thought it was worth adding in. Thanks. Heat loss calculator - SuperJohnG.xls.xlsx Floor heat loss and UFH calculator - SuperJg.xls.xlsx Looopcad - SuperJohnG.PDF