Search the Community

Showing results for tags 'more work than it’s worth'.

-

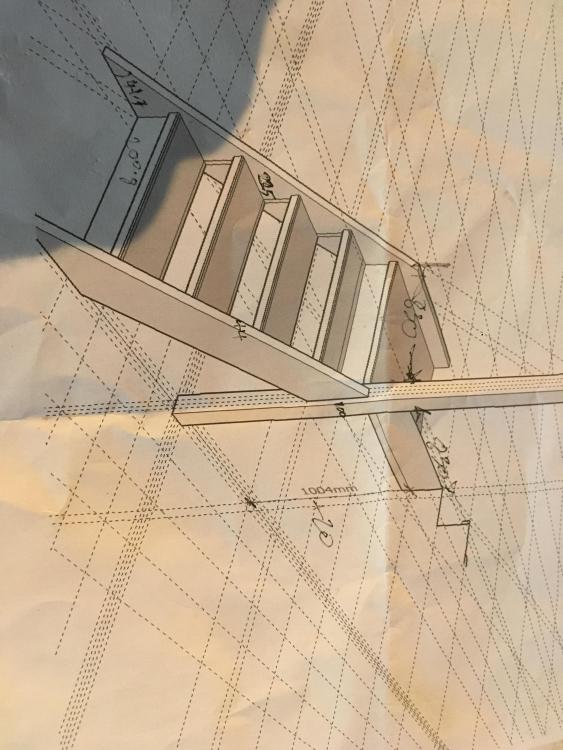

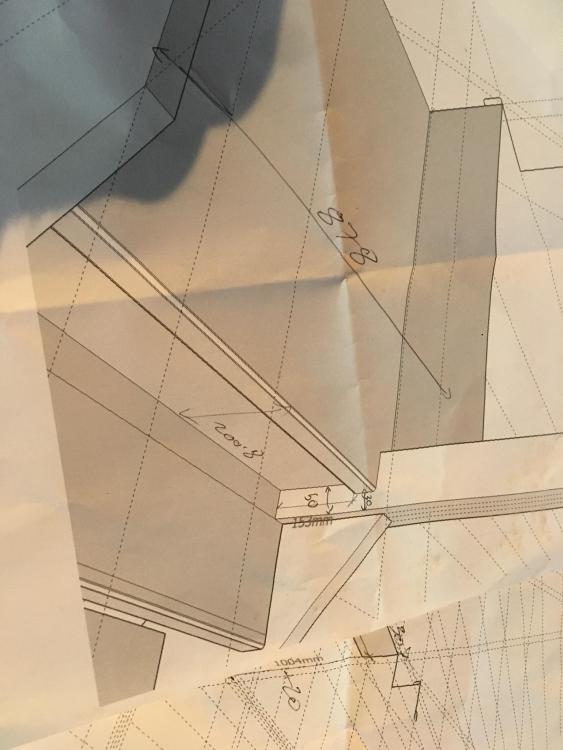

I was going to add this to the stage 1 thread but I feel it deserves its own thread. I am finally starting to make my staircase , all those years that the piles of rough sawn trees have been getting in the way are coming to an end. Yay. I should think some of you already know I started this project a good couple of years ago by cutting down a dead oak tree in the meadow. If not I will provide links to the beginning of the story when I get inside. But either way check out all the progress. The oak is starting out in roughly 55x600x3400mm planks that I slabbed with the chainsaw mill, From that they get laid onto some trestles and cut to useable widths with my skill saw and 3 rails connected together. i found these here little rollers very helpful when trying to get the full slabs into the rights place. Then I put under the little batten to stop it moving while I cut it. so we now have reasonable width 55mm oak planks. Most are over 300mm all have 1 straight side but otherwise they are very rough from the chainsaw. thats is how I left all but 2 lengths because I wanted to get my head around the newel posts. The 2 I put over the planer have come up very nicely so far, The strings treads and risers will be made from the oak if I can get enough out of it but it is looking promising so far. The newels and spindles will be ash. The ash started as roughly 120x600x3900 slabs so I am having to cut them from both sides with the saw but with the rails they are coming out rather well. as for converting the timber i have gone gone a little further with the ash. First job is to cut them to usable length. Then they get pushed over this overhand planer bow up until I get a consistent cut. Then I repeat the process on an adjacent side while making sure my new flat face is hard against the guard so I end up with 2 straight sides and one square corner. from there i take it and put it through the thicknesser useing those faces as references, this give a nice straight even thickness post. now I know what final thicknesses I can achieve with the wood I have I have started making the first jig for housing the treads in the strings. I say first because I will probably end up with at least 2-3 as the lower flight will have draws as risers. After the landing there will be a standard flight finishing with 3 winders at the top. I modeled it all on cad first to optimise the width so it finishes nicely after the winders. its all just lines on ply at the moment but I’ll be getting the router out soon, and thats about as far as I have got. I’d better get back to work

- 95 replies

-

- 7

-

-

-

- stairs

- homemade stairs

-

(and 2 more)

Tagged with: