-

Posts

35 -

Joined

-

Last visited

Everything posted by westcoast

-

Microcement people are coming back to sand down whole tray and re apply microcement so waterproofing is not an issue im just wondering if I should pour concrete in the hole for strength or match the screed material (sand and cement)

-

Annoyingly after final floors went down (microcement) we noticed shower drain rocking and subsequent cracking of microcement. turns out linear drain wasn’t seated correctly into mortar by plumber - 5mm gap under ‘wing’ of drain. Gap fixed now with epoxy. You can see I removed a lot of screed cement during my investigation: should I repair this with concrete or sand+cement? in any case I’m thinking of using some steel dowels to connect all the elements. its about 100mm deep but only 15mm deep over pipe!

-

Harebrained idea #43: We’re having an extremely dry September so I’m trying to dry out the roof as much as possible with dehumidifier. The plan is to block scupper drain and fill the roof with about an inch of water and add a tracing dye. Interestingly I cut some of the EPS out and found it to be dry higher up away from OSB..

-

Cool, I dont understand 'brought down the walls' though? We have a parapet design, so surely if should be 'brought up the parapet wall' to keep condensation moisture within - like a big basin or swimming pool?

-

Interesting Does Alutrix have any 'self-healing' properties similar to bituminous nail tape? Any VCL I put in is going to be riddled with screw-holes from the GRP fixings...

-

Apologies, I dont have photos yet, and now i've been called away to work (for 2 weeks) UPDATE: - I went up on the roof, swept and cleaned.. examined every inch of the GRP in pooling area especially along joints - no evidence of cracking or de-lamination - I spoke with our supplier, he said typically its unlikely to be a leak, but he's happy to come back and inspect His first thought was condensation and he asked what kind of building works we had recently carried out. I told him 65mm of liquid screed about 1 month ago! We vented the house for a week during the drying process, but doors and windows closed since (we have air-tightness membrane 80% installed). He advised to fully vent the house for a few weeks and monitor the situation. I have taken a 120mm hole-saw and punched out the worst of the damp OSB and exposed the wet EPS to help drying.

-

Thanks for this reply. you’ve helped me come to the conclusion we will have to cut open the fibreglass at some point: - Cut hole in fibreglass - Remove insulation - Cut out bad OSB - Replace with marine ply - Repair DPM - Lay some kind of bituminous product in fixing line (pro clima naideck or similar) - Replace insulation and get fibreglass people back to hopefully repair under warrantee! This will solve both possible issues. Unfortunately I won’t be able to carry out this work until next summer, so for now it means continuing the build with a damp spot🫤 I will continue to check for any pinhole leaks tomorrow.

-

Irish west coast! will take some pics tomorrow

-

Still following up on possible leak but: Although its been wet, its also been very warm and very humid at times. A LOT of variation in the weather right now. The house is unfinished, but well insulated (200mm external insulation, 150mm kooltherm under screed). Some hot days Ive open the door and been greeted with cool air from the day before Some chilly mornings i've been met a nice warm air from previous day. Is it possible condensation within insulation is the culprit?

-

BTW thanks everyone

-

Scupper drain happens there through parapet wall - exit pipe fully fibre-glassed, I dont suspect drain to be leaking because wall is bone-dry. Yes, some pooling happens around scupper drain, I will go up on roof for a look now for any problems.

-

Hard to tell. We had a quite a wet install so some mold was present immediately after install, after about 6 months I checked the dark area and it seemed bone-dry. Since then I've always assumed it was dry.. but maybe it was getting a little damp on-and-off. Very, very wet weather recently.

-

The flat roof 9x9m has quite a good fall on it all converging at this point. So my theory is all condensation will collect at this point too. the fibreglass team seemed very professional, 30 year guarantee etc..

-

Hi there, my warm flat roof is damp in lowest spot. roof buildup: -fibre glass -200mm eps -waterproof membrane (turned up and over insulation) -18mm OSB -Timer I-beams - VCL (pro clima intello) It’s a new build and the joists are still bare inside. Fibreglass roof +insulation has been installed for over a year. My theory is that the fibreglass installers used long fixings to fix into roof deck. This punctured the waterproof membrane (dpm) and has allowed the condensation present in the insulation to seep onto deck and collect at lowest point. Solutions!? maybe I should carefully cut this bad OSB out and stick some VCL (intello), fleece-side out to wick moisture into the house and evaporated by our ventilation? thanks, any reply’s would be very much appreciated- bit of an emergency at the moment!! J

-

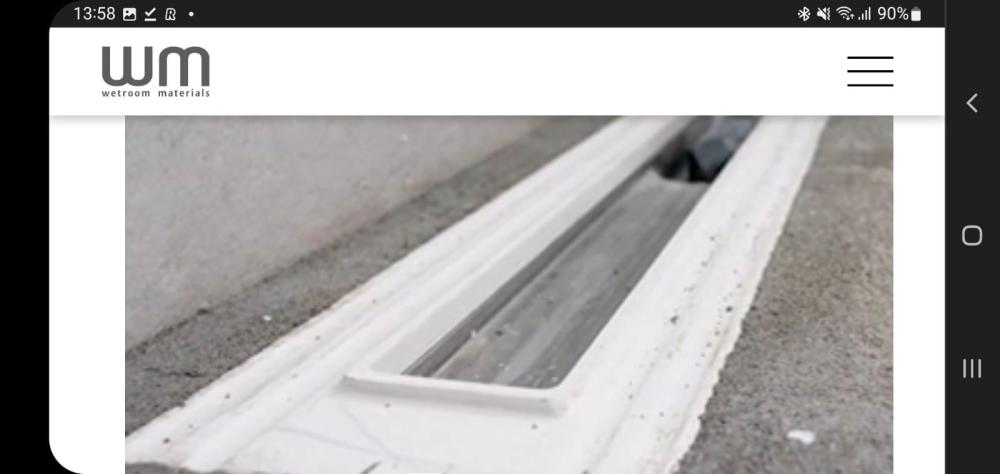

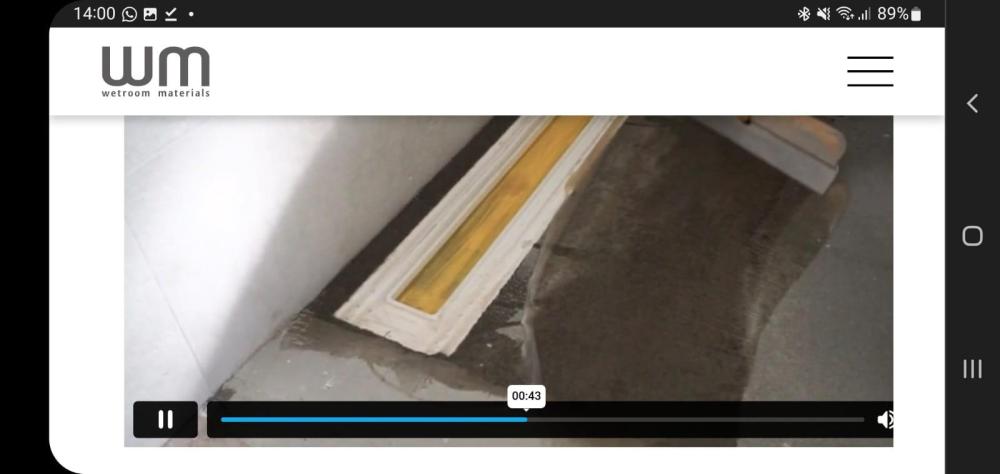

Linear wet room drain (for use with microcement)

westcoast replied to westcoast's topic in Bathrooms, Ensuites & Wetrooms

OK interesting. I'm now trying to work out if any waterproofing measures are needed when using microcement. Microcement (resin based) is 100% waterproof ...but i'm concerned about the product cracking at interface between Sand+cement and drain -

Hi all, Im trying to figure out how to install this drain. The manufacturers are not being very helpful and are just passing me off to tradesman who dont cover my area. The video shows you just make a traditional sand+cement slope to the drain - simple enough: But then the installer applies some king of resin layer to waterproof the system before moving on to Microcement: What kind of product do you think this is? My Microcement installer has no idea and does not want to be responsible for this! Thanks, any help would be much appreciated

-

Adding extra insulation to the wall service-void?

westcoast replied to Dreadnaught's topic in Timber Frame

I'd like to know the answer to this too, Im planning on doing away with the service cavity and use 50mm insulated plasterboard everywhere, except where services run..- 8 replies

-

- u-value

- insulation

-

(and 1 more)

Tagged with:

-

50mm liquid screed UFH with Sunamp as storage

westcoast replied to westcoast's topic in Underfloor Heating

sorry, I don't understand this, I'm not looking to 'overcharge" my Sunamp. I plan to use primarily solar energy to heat the Sunamp. If its cloudy or short winter days I will use supplementry E7 electricity to complete the charge for the next day. -

50mm liquid screed UFH with Sunamp as storage

westcoast replied to westcoast's topic in Underfloor Heating

No, solar array + E7 + Sunamp(or cylinder) for DHW This is what got me thinking about Sunamp in the first place - i could store E7 energy with minimal loss and inject when needed Hmm, this is another factor I hadnt really considered. ASHP would protect me more for future energy price-hikes 🤔 -

50mm liquid screed UFH with Sunamp as storage

westcoast replied to westcoast's topic in Underfloor Heating

Thing is, I believe the house will need very little space heating, prob a pulse in the morning and a pulse in evening for coldest winter months. Pay-back for ASHP could be quite long time. Wonder if direct electric heating (Willis or otherwise) would actually make sense in my situation. Do ASHP units mind being powered-off for 8-9 months of the year? -

50mm liquid screed UFH with Sunamp as storage

westcoast replied to westcoast's topic in Underfloor Heating

So is the general consensus for best value still: heat pump + storage cylinder for space heating? -

50mm liquid screed UFH with Sunamp as storage

westcoast replied to westcoast's topic in Underfloor Heating

Thanks Dave, fair enough, that does sound like the sensible option.. i might be a bit fixated on this technology! The risk of failure though I might be willing to take as the design is inherently simple e.g. no moving parts or corrosion to worry about. 10 year guarantee @ ~3000 euro. A recent look at the last page of the Sunamp megathread here looks like the mood seems to shifting in favour of the newer units. -

50mm liquid screed UFH with Sunamp as storage

westcoast replied to westcoast's topic in Underfloor Heating

Thanks for the reply! Sunamp has about 4x better energy efficiency in terms of heat loss compared to cylinder, no maintenance, much smaller unit, simple install, no discharge pipework etc.. (3x the price though..) Maybe A2A is the way to go.. I've heard of lot of negativity about them in general. Will have to research further. Very interesting.. Another Sunamp powered by solar array + E7 -

Hello again, Looking for some advice, any help would be appreciated! I am in process of building on west coast Ireland. I only have 170mm of floor space for insulation+screed due to a mistake with large sliding doors installation. No going back now. Prob have to go with a 40-50mm liquid screed and maximise my insulation. Building facts 2 bedroom house, wall U-value 0.15, roof 0.13 Special care is being taken for air-tightness (all Pro Clima stuff) high level of thermal mass (block-on-flat construction with 200mmEWI - no internal insulation) partition walls all block. Around windows and 1st and last course thermal block. Approx 100m2 of UFH space heating requirements Irish winters do not get that cold, just damp. rarely into negative numbers UFH will only be used for 3-4 months of the year Solid fuel stove for chilly nights. (Double insulated flue, dedicated air intake) I'd like to keep my heating system as simple as possible and Willis heaters have been suggested but as I am constrained to a thin screed my floor will not act as a storage heater (heat would be released too early if using E7). What do you think of these options?: 1. 9kwh Sunamp + E7 electricity, SA will provide the 'storage' element then just blend valve into UFH manifold, it would be an 'on demand' UFH system rather than a giant storage heater slab. 2. ASHP and buffer tank - requires an additional tank, more complex plumbing, maintenance costs, lifespan of ASHP, higher initial cost, noise. 3. another (expensive) option would be to get a Sunamp compatible with ASHP and start with only E7 use then purchase an ASHP later if running costs too high.. (heating requirements attached) Heat loss calculator - Ballycummin.xlsx