Dunny1234

Members-

Posts

36 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Dunny1234's Achievements

Member (3/5)

1

Reputation

-

Can I use my Slinky trench for septic drainage?

Dunny1234 replied to Dunny1234's topic in Ground Source Heat Pumps (GSHP)

Thanks for the reply, that exactly what the heating engineer said! The slinky’s will be okay on the base of the trench, I’ve got 30 tons of sand to go on top for protection before soil. I feel there’s plenty of room for drainage pipes, and Ill be installing a silt filter and chamber between septic tank and commencement of drainage field. Thanks again -

Odd question, but I’ve just had my slinky trench’s dug for my gshp. I also have to install a drainage field from the septic tank. Is there anything stopping me backfilling the slinky’s, as there at 1200mm, putting in 600mm of soil. Then putting membrane, clean stone, perforated pipe, more clean stone, membrane, and finally backfilling to level off. Kills 2 birds?!?! The heating engineer says it’s a good idea, any advice would be great. Thanks

-

Thanks Nick, all done. Lovely job, back loved it.

-

Hi Joe, would this stuff be suitable for an anhydrite screed floor with water UFH? I’m installing a engineered herringbone floor. Thanks

-

Interesting post. I’m about to hire a sander to do my screed. It’s been down for over 100 days, so slightly concerned I’m really late to the latience removal party. Also, what the best way to do corners, and more detailed areas? Is there a disc I can pop on a angle grinder. Thanks

-

Vertical cladding, minimum batten thickness

Dunny1234 replied to Dunny1234's topic in General Joinery

Brilliant, thanks -

Vertical cladding, minimum batten thickness

Dunny1234 replied to Dunny1234's topic in General Joinery

Thanks Dave. And that’s using 25mm thick battens horizontal and vertical? -

Hi all, soon I’ll be installing some vertical larch cladding. I need to merge/blend in with some vertical zinc cladding. It would be a lot easier to use 25mm thick vert and horizontal counter battens to make to the 2 cladding materials merge. the larch cladding is 20mm thick, could I get away with using 25mm battens? thanks

-

-

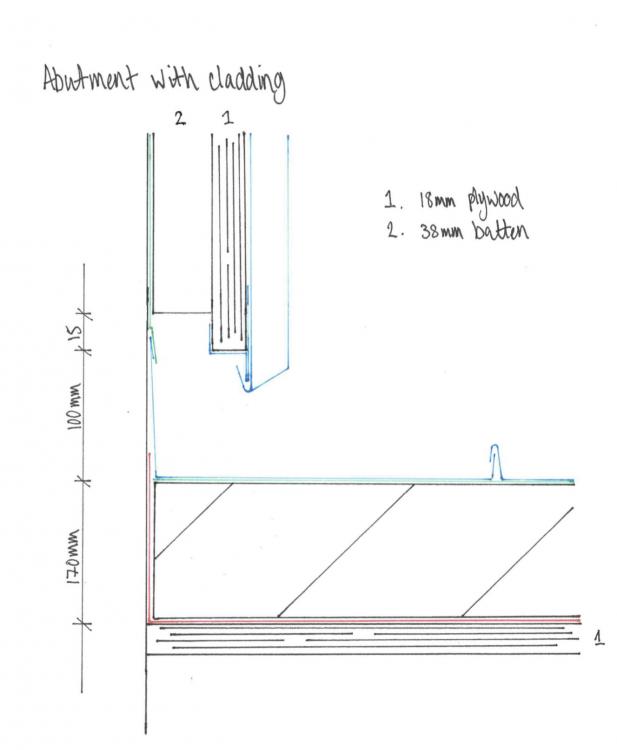

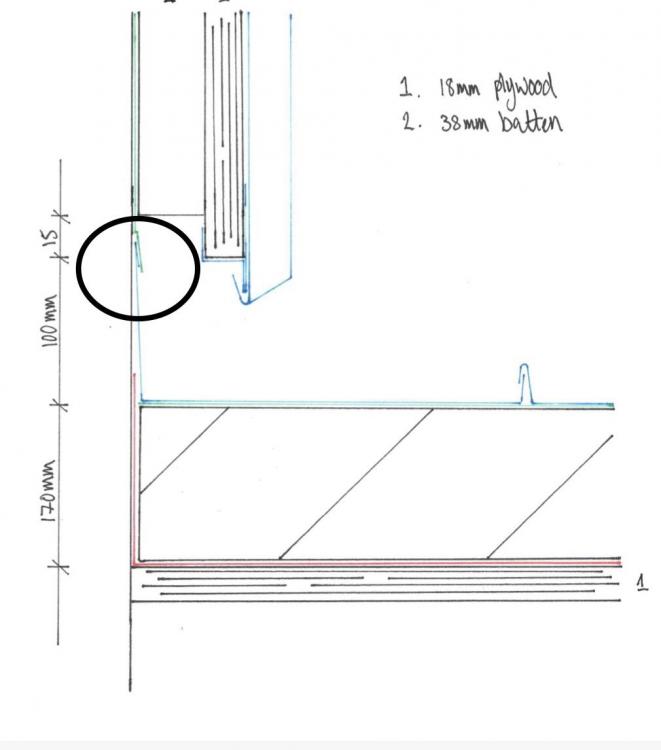

Thanks Russell. The vast majority (90%) is block wall. Zinc upstand is 100mm high, but I fold like the detail shows.do you think it needs the fold at the top of upstand, as per detail drawing? thanks again

-

Wondering if anyone can assist? Having a zinc roof done on my self build. There a few sections of where the roof meets the wall cladding abutment. The roof sheets are complete, and the upstanding comes up the wall 100mm. I’m now meant to baton wall (38mm), and plyboard it (18mm) ready for the zinc guys to clad the ply/wall in zinc. The zinc installer gave me detail to follow for all the prep work, which I’ve followed to the letter. Whilst doing the wall battons, I’ve noticed that the zinc company hasn’t put a fold in at the top of the upstand, as per pic below. Obviously, I can see this causing problems. do you think I’m being worried over nothing? Should I get the company to include a fold? Obviously, if they make a fold now, the upstand won’t be 100mm high, as per drawing, which could also cause problems Thanks, any advice would be great

-

Blinds that are compatible with Loxone

Dunny1234 replied to Dunny1234's topic in Networks, AV, Security & Automation

We decided to run both, just to have flexibility. As mentioned, everyone seems to have a different opinion on the best way of doing it. After some research, it seems the best company is ‘Cotton Mill’. They supply a decorquip motor/mechanico directional motor that works with Loxone /wired. Not cheap mind £200:for motor. if you, or anyone, has a cheaper/better solution I’d be interested. thanks -

Blinds that are compatible with Loxone

Dunny1234 replied to Dunny1234's topic in Networks, AV, Security & Automation

Thanks Will, if it’s okay, you may hear from me again? I’ve put 4 core and Loxone to each blind. There just seems to be a 100 ways to make the blind work with Loxone. Somfy seem the most cost effective blind, but does it work with Loxone? I had a nose at your insta, nice build! Thanks again -

Hi all, currently doing the 1st fix of my house. Ive installed Loxone tree throughout, and plan to have automated blinds, and curtain tracks. I’m getting a lot of different types of feedback about the best way of doing it. My Loxone installer is fairly new to it, and I just want to make sure we do it the best way. Anyone out there that has done it, or know how to do it? Im keen to keep costs down as much as poss. Does anyone have experience with Somfy blinds working with Loxone? any advice would be gratefully received thanks

-

Been Installing mvhr ducting. Whilst feeding it through posi joists, I’ve noticed areas where the ducting has been caught on the sharp bits of metal on the posi joists. It seems the damage in mainly on the ribbed areas. Is it fit for purpose? Thanks