seanblee

Members-

Posts

33 -

Joined

-

Last visited

Everything posted by seanblee

-

Shower and basin drain connections

seanblee replied to seanblee's topic in Bathrooms, Ensuites & Wetrooms

There's going to be boxing along the left side of the room for a wall hung toilet frame so I'll be running the basin waste through that, it's really just whether it's worth up sizing to 40mm or if I should just reuse the existing 32mm - my gut says 40mm is a better job... I'd love to have the shower tray flush but the joist layout makes it impossible - I really don't want boxing below and I'm not comfortable putting a 40mm hole through the double trimmer, feels like that's removing too much material. -

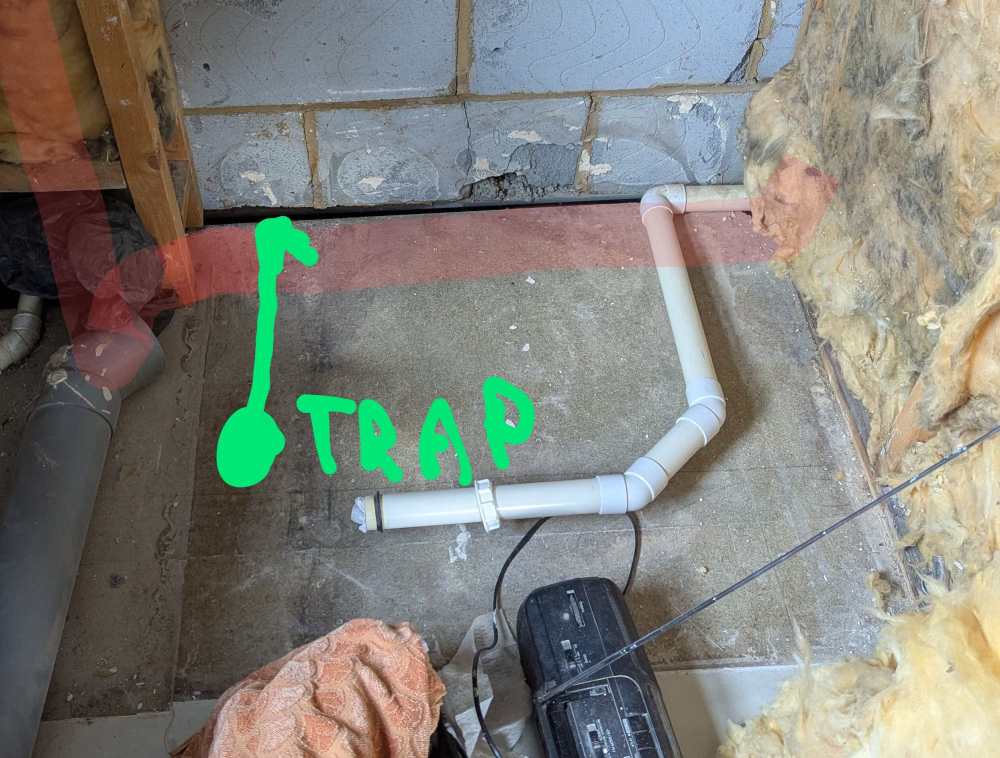

I've (mostly) gutted our ensuite and am now trying to decide the best way to provide a drain connection to the new shower tray and basin. The existing connections are as below. The main bathroom is through the wall on the right and there's a mini stack that the shower drain is connected to (along with the bath, toilet and basin in the main bathroom), with a 110mm running horizontally under the floor at the back to join the main stack on the left. Main joists run top to bottom, except there's a double trimmer running left to right next to the 110mm at the back that's carrying the joists for this section. The existing basin connection is 32mm all the way with minimal fall into a vertical drop, and the drain used to glug whenever any water was run down it. I was hoping to find some 40mm somewhere but no joy, so I'm thinking about capping the 32mm and opening up the boss next to the toilet waste connection and running 40mm, reducing to 32mm where it comes out of the wall to the basin trap. Does that sound like the best option? For the shower, the current connection from the mini stack is above floor level: The old shower tray was on some bits of 4x2 on edge and had a big upstand, so a huge step up and over. I'd like the new tray closer to the floor, so I'm thinking about capping the existing and cutting a channel in the chipboard floor, putting a strap boss on the top of the horizontal run at the back and dropping the shower connection straight into the top of it, something like this: I'd then raise the tray on a couple of layers of 18mm ply, so there's still a slight step but not as much as before. Is that the best option, or is there another way? Many thanks in advance!

-

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

I'm going to give that a try for a few days and see what the gas consumption looks like - at the moment, it works quite hard from 4-5:30 every morning to lift the temperature, and whilst it's been around 5 degrees outside, we've been using 85kWh a day, which feels like a lot to me. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

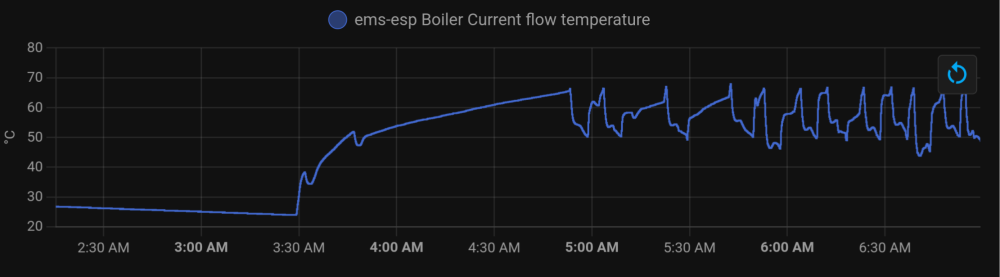

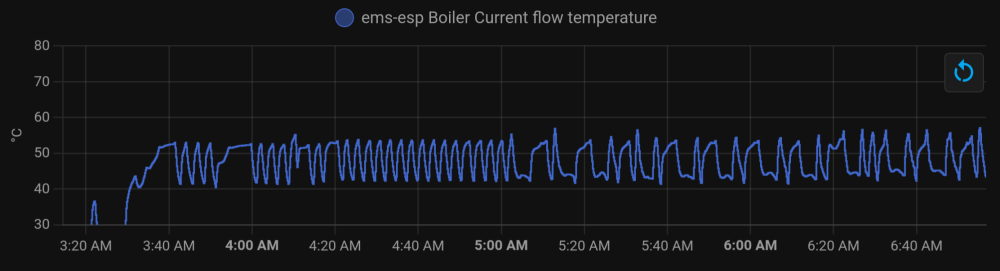

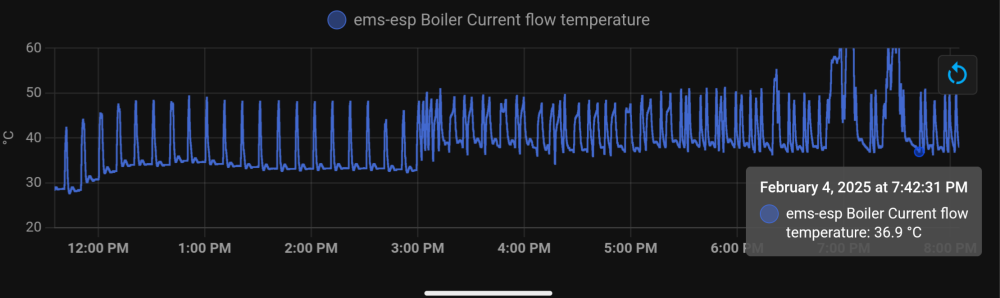

Well, I'm still running at over 60 degrees flow temperature - I think I'm ultimately going to need to replace the two vertical radiators with bigger ones to get more heat into the room at lower flow temperatures. Other than that, I think things are looking pretty good - this is the flow temperature today, and the burner stats show it running at 28% from 4am for nearly 90 minutes, so it's no longer short cycling. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

They're all back where they were, so approx 10 degrees drop across each radiator at 65 degrees flow. At this point, I think the changes that have made a difference are eliminating (most of) Evohome's TRVs, range rating, tweaking anti cycle and increasing the flow temperature. I'll give it a few days then I might try lowering the flow a few degrees in tandem with opening the lock shields a little and see what that does, but I'm happy it's at a good starting point now. Thanks again! -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

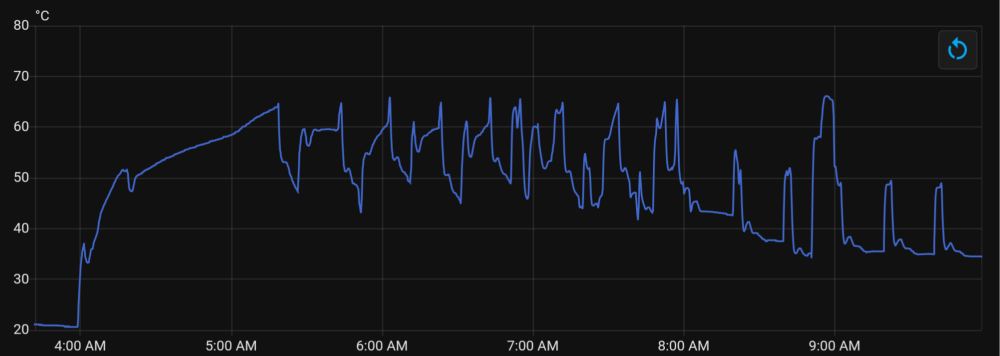

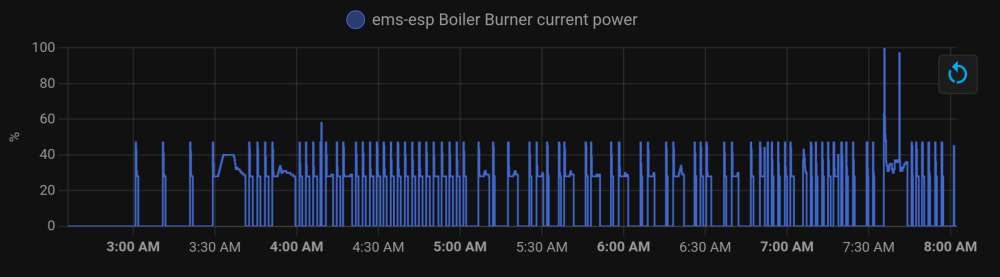

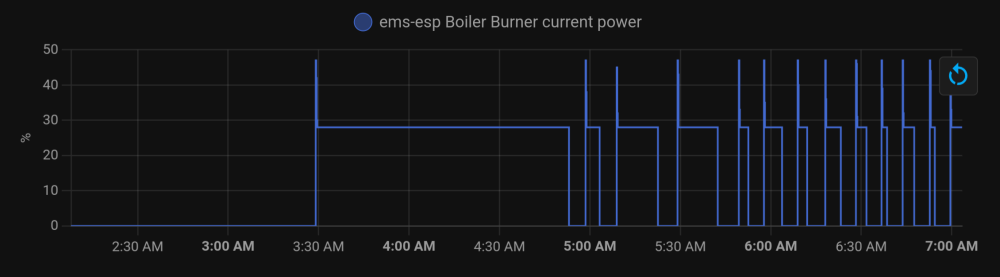

This morning is looking rather better: Perhaps more interesting is the burner power - this was yesterday morning: And this is today: Pretty dramatic difference! I might still raise the ACT a little to reduce the cycles when the room temperature is closer to the set point, but this is the first morning I can remember where I came downstairs to find the lounge at the target temperature, not 1-2 degrees below. 28% is as low as it'll go for range rating, the register won't accept a smaller number. It looks like it very briefly fires at a higher power level but almost immediately drops back to the configured setting. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

Good call, I'm not sure why I thought 40% was minimum, I've dropped it now to 28%. I reduced the anti cycle time when I was struggling to hit the target room temperature in the lounge - I've bumped it up to 5 mins and increased the hysteresis to -15K. Behaviour on this boiler is that if the flow overshoots, both the anti cycle time and the hysteresis have to be satisfied before it re-fires. I've also increased the pump overrun from 5 to 10 minutes. Thanks again for your continued input, much appreciated! -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

Thanks, yes I've played with most of that. I range rated it down to the minimum (40%) for heating (installers left it on 100%). I tried decreasing the anti cycle time to 1 minute but I've bumped it back up to 3 now. On the pump, the installers left it in the default of proportional high, which was very noisy, so I dropped it back to proportional low a few weeks after it was fitted, and now it's on fixed speed pump step 2. I only got monitoring working through HA in the past few months so I've no idea if it's always behaved like this and I've just not known, or if this is something new. I can try pulling the pump and seeing what state it's in, it's internal to the boiler though so I'm not sure how easy that's going to be. I was wondering if it maybe needed a flush. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

Unfortunately yes. I've increased the set point to 65 and it seems better, but I'll know more tomorrow morning - right now, the rooms have overshot their set temperature, so I think Evohome needs to re-adapt. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

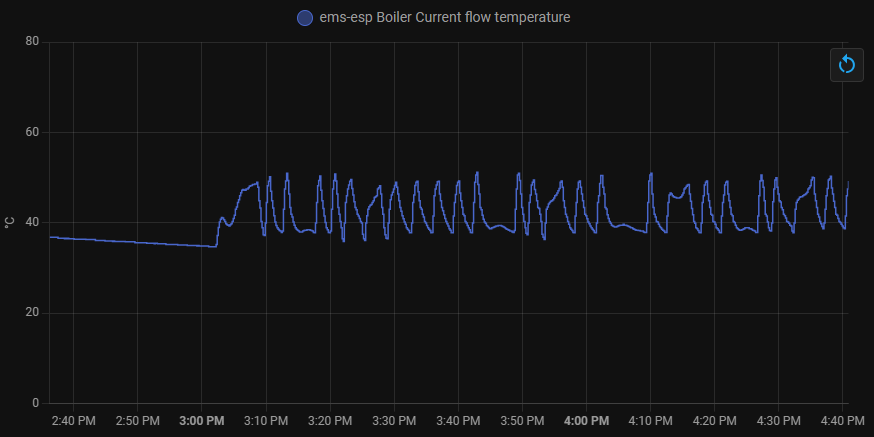

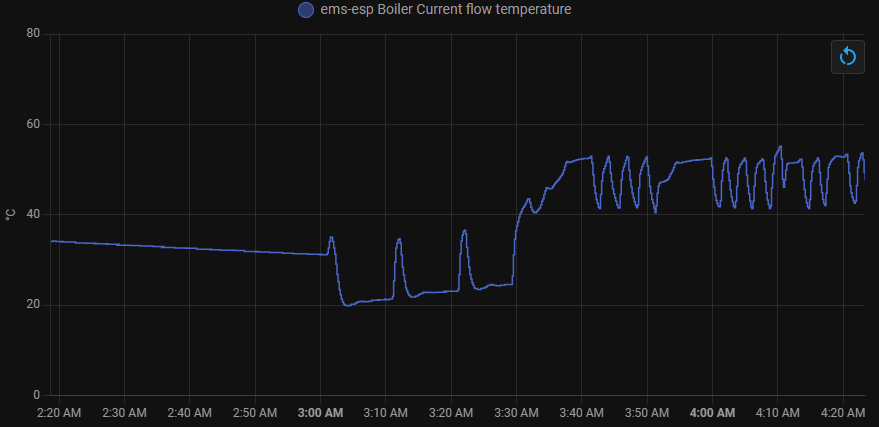

I increased by half a turn this morning and another quarter this afternoon (leaving some lockshields now wide open) and it hasn't made any real difference to warm-up this afternoon. The setpoint was 18 for the lounge during the day, increasing to 20 at 5pm - Evohome decides when to start warm-up so it hits this temperature at this time, and it looks like it kicked off just after 3pm today: Overnight setback for the lounge is 17 (dropping from 20 at 10pm), so there are a few spikes from 3am onwards where I guess Evohome is firing the boiler for short durations to maintain temperature. Warm-up proper started at 3:30am in order to hit 20 by 5:30am (my kids wake up annoyingly early!): I think I'm going to try that - increasing pump speed is out because it makes the whole system noisy (even with lockshields wide open), so the only logical thing to try is raising the flow temperature. I think I'll put the lockshields back where they were this morning, turn off the HA automation then bump the flow dial up to 60 and see how that runs. If it's stable, I'll start incrementally decreasing it until I get back into cycling. It does make me worry about a potential future ASHP - I know they don't need such a big delta between flow and return, but I don't see a way around a buffer without a full repipe, which would be a nightmare... -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

No improvement this morning. I'll try opening the lockshields half a turn as you suggest and see what that does... -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

I understand that Evohome turns the boiler on and off a few times an hour, but that's not the issue I'm having here - even when Evohome is continuously calling for heat, the burner is firing, the flow temperature is rapidly rising until it crosses the setpoint, then the burner is turned off until the flow falls to the hysteresis threshold of 10 degrees below the setpoint, then the cycle repeats... -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

-

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

When I get a moment, I'll drain and remove the vertical rads and check the diverters - mine are a bit more awkward because I've got central flow and return via a H block valve, but there are bungs at each end of the bottom tube so I'll remove those and check. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

I've removed the Evohome valves from all but the lounge radiators and put everything else back on TRV4s - that leaves Evohome controlling the two vertical rads, the boiler and the UFH (via another BDR91 to power up the zone valve, pump and actuators). I'll let you know if that helps! Should I be considering an ABV, or some sort of flow rate monitoring? -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

Oh, and there's no ABV on the system (one of the towel rails has no TRV). I also struggled a lot with balancing one of the tall radiators - I got to about 6 degrees drop, but if I closed the lock shield any more, the flow temperature started dropping too. I think it's near the end of the system, so maybe not enough residual head? However, it's also the noisiest if I turn the pump speed up... -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

Thanks folks. The Evohome is currently switching the boiler by relay and I've got a spare round thermostat, so I could try taking Evohome out of the picture and pairing that directly instead, but I think it does TPI control too. I'm not sure about the heating flow and return, it's possible it reduces to 15mm later in the run. When I balanced radiators at 65deg flow, I was going for a 10 degree drop across the rad - should I be aiming for more than that? I've got monitoring of the boiler through an EMS-ESP and that shows it dropping the burner to 28% within a few seconds but the flow temperature continues to climb rapidly (and it continues to climb for a bit after the burner is turned off too). I've tried the pump on proportional low but I'm currently running it on fixed speed step 3 (of 7) - any faster and the radiators get quite noisy. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

I did try Opentherm with Evohome using the Nefit adapter that was suggested but it didn't work properly - the boiler didn't fire most of the time and just ran the pump so the house got very cold. -

Boiler short cycling with low flow temperatures

seanblee replied to seanblee's topic in Central Heating (Radiators)

I've got Evohome with smart TRVs but I'm starting to phase this out - I've put two zones back on "dumb" TRVs and synchronised the schedule for the other downstairs zones to try and make sure most of the system is "open" at the same time. The area I'm struggling with the most is the lounge - this has two vertical aluminium radiators (Milano Skye 1800x375, 840W at T50) but these have very low water volume and I get a lot of cycling when it's the only zone calling for heat, so I think I may need to swap them for something bigger. -

I've got a Worcester 38 CDI Classic combi boiler supplying a small 90s 3 bedroom house (8 radiators, 2 towel rails, UFH in kitchen extension). Pipework is 22mm primaries at the boiler with 10mm microbore drops to each radiator. I've set up some automation in Home Assistant to provide a degree of weather compensation and lower the flow temperature on warmer days, but I'm finding the boiler is struggling with this - unless the flow temperature is 65 or above, it hits target after about 30-60 seconds then shuts down the burner. I can see from the metrics that it's modulating down to 28%, which appears to be the minimum. I think my problem is the microbore pipework (so small water volume) and the rubbish modulation ratio of the boiler - I think my heat loss is probably around 6kW and the lowest modulation is over 10kW. Is there anything I can do to improve this (buffer/volumiser, increasing radiator sizes, ...), or am I fighting a loosing battle? Plan is to replace the boiler with an ASHP in the future but it's only about 6 years old so I was hoping not to do this just yet. Many thanks!

-

Trimming glazing bead seals to reduce air leaks

seanblee replied to seanblee's topic in Windows & Glazing

Given the state of the rest of the installation, I was unsurprised to find the glazed unit wasn't packed in correctly on my test window - it was sitting on a couple of packers at the bottom but otherwise free to move. I've packed it on all four sides and inserted some backer rod around the unit, so I'll see what happens - only another 16 units to sort if it's successful...! -

Trimming glazing bead seals to reduce air leaks

seanblee replied to seanblee's topic in Windows & Glazing

Thanks, I'll take a look. My only concern with foam would be blocking drainage holes in the profile - I'm assuming there would be some to drain any water that got past the external frame-to-glass seals? I saw another thread where someone wedged foam backer rod between the glazing unit and frame, perhaps that's a safer option? -

I recently bought myself a thermal imaging camera, which I've started using to try and find issues with cold bridging and inadequate insulation. I've already fixed one issue with the back door cams missing their receivers so not pulling the door onto its seals properly, but I've found another issue with almost all of my (2007) double glazed windows - they leak air from the seals on the beads at the corners. My newer windows have beads that are mitred at the corners, so the seals meet neatly, but it looks like the shorter beads here are scribed around the longer beads and the longer seal is holding the shorter one away from the glass. Any thoughts on the best way to trim them to resolve this, please? Thanks!

-

Oh, couple of photos from the inside of the vents, and the damp reveals that are still drying out - you can see the mould on the caulk around the trim that I need to clean once again, fingers crossed for the last time this time!

-

The Higroster vents finally arrived from Brookvent last week (delays at the Brevis end apparently), so I spent a few hours over the last couple of days fitting them. As I mentioned, the windows didn't have trickle vents before, so I ended up making a couple of templates from MDF, one for inside and one for outside, then removing each opener in turn and routing a slot into it. All went well and they're now fitted to all bedrooms and the lounge and playroom downstairs. I also removed the PIV yesterday and stuck it on eBay. I'll be keeping an eye on things over the next few weeks but initial signs are good - much less moisture inside the bedroom windows last night and the reveals stayed dry, which is better than the night before. Thanks again for the advice!