PickaxePete

Members-

Posts

11 -

Joined

-

Last visited

PickaxePete's Achievements

Member (3/5)

0

Reputation

-

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

Thanks for the input ProDave. I'm at the stage where I've removed the actuator head and it's still not heating the zone. I've ruled out: Airblock - have flushed the zone (or flushed to the best of my ability). Actuator - removing the head makes the zone fully open. Still not working. Mixer valve - moving the thermostatic valve increases temp as expected. Mixer is working. Pump - other zones are working ok, and I can detect (by feel) the pump operating at different speeds when chaning the settings (I, II or III) Pressure - manifold is sitting up at same pressure as the boiler pressure I'm at a bit of a loss of what to try next. I think I'll try cleaning / the flow valve on the weekend as that's literally the last component on this problem zone that I haven't checked. I may have to bite the bullet and call a professional! Shame, as the components and setup all seem to be easily user maintainable if you're well informed. Any input always appreciated. Lee -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

Having left this a couple of days to see if there is any difference, I can confirm that the pressure has risen to between 1 and 1.5bar on the manifold gauge, which is in-line with what is being shown on the expansion tank gauge, so I *think* the pressure is fine (for now). I've still got zones not heating up - the kitchen zone is a good example. Supply pipe hot Actuator valve open (as far as I can tell) The return pipe is cold Floor in zone is cold Any clues as to what I can do now? I think my next step will be to switch the actuator head with a zone I know is working, see if that works. If so, might be able to pin it down to the actuator. Would the flow valves have any bearing on performance here? Should I change these for new ones or check if the old ones are ok? Lee -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

no gauge on the boiler itself but the reading from the expansion tank gauge is about 2 bar. -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

-

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

Hmmm. I've been thinking about this - I don't think the gauge on the manifold is telling me the pressure of the manifold at all, is it? The manifold will be at the same pressure as the boiler / expansion tank, i.e. approx. 2bar, right? This gauge attached to the manifold is for telling me the pressure of the water only when the return valve is opened (i.e. pressure testing on installation)? If correct, I've answered question (1) myself. Thoughts? Lee -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

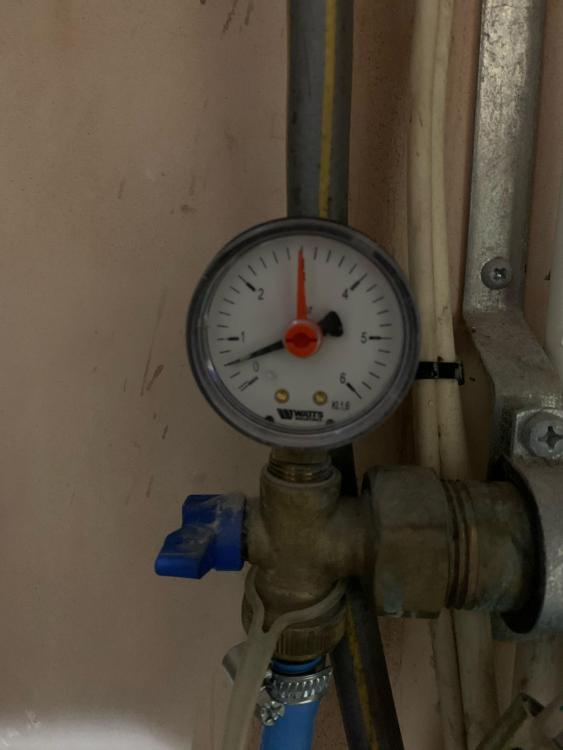

I found the filling loop near the expansion tank (not near the boiler in my case), so filled it up to 2bar using the valve (went a little over as per pic of expansion tank & gauge). This is something that I have had to top up every couple of months in the past, as it drops down to around 1 bar or less over that time period. With additional knowledge from undertaking this flushing activity, constantly dropping pressure in this system seems like a "bad thing". I've been doing this for years! So couple of follow up questions: If the boiler pressure is at ~2bar, should the UFH be at the same pressure? The gauge on the UFH manifold indicates otherwise (see pic of gauge att ~0.5bar). What should I do here? Should I be worried about the slow loss of pressure over months from the boiler? Is this an indication of a slow leak somewhere? If so, what can / should I do about this? Regards, Lee -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

Cheers - will have a look around. Lee -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

Thanks for the reply & guidance @PeterW. I ran through the flushing today on all my zones - wasn't as hard or scary as I first thought! I've also got the inhibitor on hand and will look at putting that in shortly. "Open the manifold isolator valves. Let the system run for 10-20 mins to circulate the inhibitor and then top the system pressure up to 2bar. Run again, and bleed the air from the vent. You may need to do this 2 or 3 times, and repressurise to 2bar each time. " How do I get the system pressure to 2 bar? Is it simply closing off the return valve and keeping the supply valve open? I thought the standard mains supply was only 1 bar, so how would I get it pressurised to greater than the input pressure? After flushing the system is sitting at 0.5 bar, but I've closed the return valve and seeing how high I can get it by keeping the supply open and water flowing. Thanks! Lee -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

Thanks for the detailed reply. I'm kind of resigned to performing a flush, which will give me piece of mind that it's been checked and re-filled and any crap / air is removed and cross this off the troubleshooting checklist. I'm going to gear up to do this one weekend. Some questions though, if I may to make sure i';m understanding correctly? I've attached an image to confirm the components you are talking about before I break something expensive! Can you confirm: Top yellow circle is the flow / supply (water in) Bottom yellow circle is the return (water out) Blue circles are the manifold isolation valves Green circles are the flow / return isolation valves "Mark all the heads and remove them - you want to manually flush the loops - and then open the flow and return isolators and push the first pin down." Remove all the actuator heads? They are already marked from installation, but I'll take a photo record to make sure I have a reference. I thought by removing the heads, all zones would becomes open? By pushing the pin down would the close the zone? "It should have inhibitor in the system but if it’s 10 years old then it should be replaced anyway" How would you get inhibitor into the system? Is this something a layperson could do or is special tooling required? "You may find you need to bleed the manifold after it runs for a while - that’s the white bleed valve on the top left. " So, after the flush /re-filing, I should bleed any air lef tin the manifold. Does the valve just turn to belled or do I need to un-screw it? I am assuming I don't need to touch the flow valves? Regards, Lee -

Nu-Heat UFH - Problems with some zones

PickaxePete replied to PickaxePete's topic in Underfloor Heating

Thanks for all the feedback. I'll try to answer questions where they have been asked: "Could be a balancing issue if the problem rooms are the longest loops." The rooms where this is happening are likely the longest loops, however this system has been operating for 10 years so I'm hoping it was installed and balanced correctly on installation! Can a system come "out of balance" over time? How would I troubleshoot this as a potential issue? "One thing I would note is the pressure is low - is this run from a boiler and is there an expansion tank on the system ..? When was it checked last ..?" It is run from a boiler and there is an expansion tank installed. I noticed the pressure gauge too. We recently had a local heating engineer in recently to have a look, and he thought the system pressure looked ok, although the pre-set on the dial seems to indicate it's under where it should be. Not sure he was entirely accurate.... In your experience, should the pressure in the system be higher? The gauge on the expansion tank is set to 1 bar (cold). "...possibly the thermal actuators are leaking , they rely on expansion of the fluid so it’s possible that there is a slight loss , try removing them to see if the system operates better." You mean the actuator heads? By removing these it should open fully (by default) and thus troubleshoot if this is an actuator issue? "...and did I read that right 55 degree flow temperature ????" Yes - I think the local heating engineer that came to look turned it up from 45' to 55'. Based on your apparent alarm at this, I've turned it down! I am assuming that this temp is higher than you might expect? "Where are you and how cold is it?" Essex (East Midlands), so definitely not as cold as the Scottish Highlands, but as the nights are fair drawing in, you can feel the cold in the large rooms when the system is not operating. I've got some other questions about @PeterW's response, but I'll put those in a new response. Thanks! Lee -

Hi All, Hoping you lot can help me with an issue I'm having with my UFH. I think from reading several threads on here (and drawing parallels to my own situation) I have an idea on what the issue might be, but would like to hear from practiced experts with more than my rudimentary knowledge of UFH! Onto the issue... Setup Bungalow UFH, no upstairs. Nu-Heat installed 8-port manifold servicing 8 zones System installed about 10 years ago when the property was built. Images of manifold setup attached. Problem Two of the zones (Living Room & Kitchen) are very inconsistently warming up. They will heat up, but not super warm and take ages to do so. Anecdotally "not as hot as it used to get" according to my wife. Troubleshooting so far All zonal thermostats seem to be working ok - turning them up triggers the actuators. Actuator pins are all working as expected. Have had the actuator heads off and checked. Pump is operating as expected - can feel the difference in switching it up to II or III. Thermostatic valve is working fine - input temp on manifold is reflective of changes to the valve temp setting. Flow valves are all ok. Manifold pipes out to the ON zones are hot. Manifold pipes back in from the ON zones are warm. Manifold pipes out to the OFF zones are cold. Manifold pipes back in from the OFF zones are cold. I of the impression that this is pointing to an airlock somewhere in the system, possibly affecting the Living Room & Kitchen zones as they are the furthest away from the manifold? Any input on what else I can do / troubleshoot in this would be very helpful and much appreciated! Regards, Lee

.thumb.jpeg.72fe56259c9136e9cb71f904105361a6.jpeg)