bradders3109

Members-

Posts

71 -

Joined

-

Last visited

bradders3109's Achievements

Member (3/5)

17

Reputation

-

Has anyone got any updates in this area? I have run into this issue. We have a dormer in the loft space which is the master bedroom. There is a large opening window to the side which exits onto the flat garage roof albeit with a ladder. We are required to have a fire protected hallway as the property is three storey. The regs around fitting fire doors will clash with the air flow for the mvhr system and I'm not into that idea. Also we would like a large slider on the doorway into the main kitchen/diner/socialising room. I've read that we can go down the route of a performance based solution supported by a fire officers report. This would involve a misting system, wired smoke alarms, heat detector in kitchen and automatic shut off to the mvhr. This will get us away from fire doors but I'm open to simpler suggestions if anyone has anything. I do like the slide idea ; ) Cheers

-

Spent the week using stairbox design tool before posting on here to see if I can find a way round the issue. Fully understand that I won't change the regs but was just trying to understand the rationale for on the face of it what appears a bit of a strange regulation. I get your explanation and to be fair as you say it really doesn't matter what the rationale is, as you've said I can't change the regs. I'll give stairbox a call tomorrow. Thanks for the replies

-

I thought so. I just don't understand how a 700mm landing is fine with a 700mm staircase but not with a wider staircase. Surely it's about having a safe area at the top of the stairs and if 700mm is safe for a 700mm wide case why not for a 900mm wide case? Like most of us who self build I've come across many regs that don't appear to make sense but this one has to be the daftest.

-

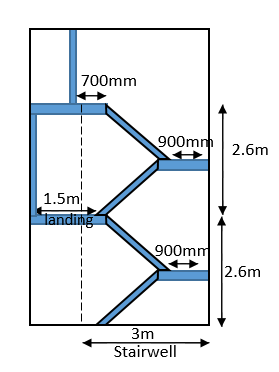

Thanks for the responses gents. Mine isn't a new build but a renovation with a large extension. The staircase will be in the new part of the house and my understanding is that part K applies. I've tried to mock up the stairwell in powerpoint to give a better idea, hope this helps to visualise. Any suggestions are greatly welcome.

-

Am I reading approved document K correctly? My stairwell is wide enough to accomodate a 900mm wide staircase and this is what I would like. It goes up to a half landing which is 1200mm deep. It then turns back on itself and rises to the first floor landing which is about 1500mm deep. We then have a dormer and the staircase would rise to another half landing again 1200mm deep. Then again turn back on itself for the final flight to the domer room which would again preferably be 900mm wide in keeping with the rest of the staircase. The problem arises at the landing to the dormer as this is only 700mm deep. If I'm reading the regs correctly: The landings at the top and bottom of each flight should be at least the width of the smallest width of the flight. So in essence the 700mm landing would be fine if I reduced the last flight width to 700mm but wouldn't be acceptable if the last flight remained in keeping with the rest of the stairs at 900mm. What could be the possible reason for this regulation?

-

Perhaps not worded particularly well but the graph shows cycles or approx 95 minutes.

-

Looking at my consumption from yesterday it looks like a cycle lasts about 95 minutes with 70 minutes being on and 25 minutes being off.

-

I thought a cycle was the entire period the pump was running and standby. Eg: on for 25 minutes, standby for 5 minutes would be a 30 minute cycle.

-

I'm happy with the internal temp and using the burner when required. This makes sense but I'm not sure how to tell from the app if the unit is cycling more or how to resolve it for increased efficiency?

-

Just read through the thread to update myself and much of the discussion is a bit above my pay grade.🤔 Back to the heat geek install. We have open loop UFH. Everything run from the Heat Pump with no additional circulation pumps. Weather Compensation active and Heat Curve set to 0.25. Desired temp set to 20 degrees. The good Heat Geek agreed to honour the original quote of £11,054 for the install. Prior to commissioning in early Feb we had very high humidity in the original solid wall part of the house and lots of condensation issues. These have now disappeared and the relative humidity in that area now fluctuates between 32% and 44%. The 20 degree internal temp is rarely met by the UFH and it fluctuates between 18.5 and 19.5 degrees. As mentioned by others on the thread depending on time of day this could feel either cold or warm. When required I boost the temp by lighting the log burner which I like otherwise it would be redundant. Since commissioning the COP just for heating has been Feb 5.9 and so far in March 5.5 which I find a bit confusing since March has been warmer I would have expected a better COP? We have lived without running hot water or heating (stand fast log burner) for four years whilst we have been doing the build. This install has revolutionised our lives. The bad Some of this may be a bit picky but I've included it for completeness. The spark intended to install the heat pump isolator circuit on a type A rcd as he had with all of his previous installs. The Vaillant manual specifies a type B and anything else would invalidate the warranty according to Vaillant technical department. Following a protracted discussion a type B was installed. On day one I walked the install team around the property and explained the build to them. I informed them about the make up of Nudura part of the build, concrete core with rebar at various intervals and polyprolene web within the Nudura. I showed them where to drill in order to miss the rebar and webs. This either didn't sink in or was ignored. They hit both rebar and webs which then took an age to drill through the walls. Some of the pipework was not lagged and I had to do this myself after commissioning. The discharge from the cylinder goes into a soil pipe and the tundish should have had a dry trap seal to prevent foul smells coming back through it. This wasn't done and I've subsequently changed it myself. The condensate does not align with the installed drain and the heating wire and tundish have not been installed? I am awaiting rectification. Hot water thermostat for the cylinder was not fixed in place and loose fitted which resulted in a bit of movement and on one occasion it had fallen out of its housing. Following commissioning the installer informed me that there was a gassing issue with the pump which was causing excessive noise and defrost cycles. He instigated a visit from the Vaillant engineer. The engineer came out and said that there was nothing wrong with the pump. I referred this to Heat Geek and they have decided that there "Heat Geek Elite" installer was wrong and the pump is fine. The concerns I had about the high cost of sundries was perhaps unfounded as there are more components than I expected (see picture). I should say that Heat Geek are just an umbrella organisation and as with all of these things the actual quality of the installers will vary. Disregarding the install issues we are very happy with the outcome and comfort that we now have. This is in danger of turning into war and peace so I'll leave it here.

-

Well intended government schemes that have the desired effect and consumers engage. unfortunately this leads to a shortage of installers to meet demand. Market rules apply. Demand outstrips supply and prices go up. Often leads to lots of cowboys jumping on the bandwagon I’m confident that heat geek installers don’t fall into that bracket.

-

I do agree but with the bus grant I'll be paying £3.5k so it's only marginally more than the cost of the heat pump if I was to do a self install. Other quotes that I've had are in the same ball park.

-

Hi All By way of an update: Heat geek have now agreed to honour the original price adjusted with the removal of the radiators and associated labour. I am much more comfortable with a final price of £11,054. Still perhaps a little expensive and I'll be interested to see what sundries they fit. I will updated this thread with comments on the quality of the install and the SCOP achieved which heat geek are guaranteeing at 350%.

-

Unfortunately they are quoting £6k after the grant so not much difference really. Is the demand for heat pumps so high that installers are now just thinking of a number and then doubling it when it comes to quoting?

-

As a sparky I consider sundries to be minor items that wouldn't amount to much worth itemising. These sundries are more expensive than the heat pump. Bonkers