MrTrevithick

Members-

Posts

26 -

Joined

-

Last visited

Personal Information

-

About Me

Slightly eccentric off grid bunker living anarchic bloke.

-

Location

Wild West.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

MrTrevithick's Achievements

Member (3/5)

15

Reputation

-

Sealing an underground structure

MrTrevithick replied to MrTrevithick's topic in Waterproofing & Sealants

Good tips, the low level mushroom idea had already popped in my head to be honest but that now confirms that plan. It’ll need to shift a lot of air around in the generator one to keep the machine cool. The wall will be just at the buried back with a door at the other end, I like the idea of the gravel drain. Cheers -

Another little question. I have 2 Anderson shelters and intend to build them into the side of the protective hump near the west entrance tunnel, one to be used for the standby generator and the other as a garden shed (the Allen Sythe can live in there). I am missing the end panels so I was intending to build a concrete wall at the far end but I need to seal it with something. Now it won’t be dealing with much water as the hump drys out very quickly it appears, but I could do with keeping that generator happy. So can anyone suggest a suitable sealant? A paint on type product would be perfect. Cheers

-

Interesting points, thank you. The coming of age seems to be between 3-5 years (or a couple of weeks after the guarantee runs out), as for the build quality of the lodges (which they sell for well over £300k) is getting better but the early ones was terrible but, as pointed out, these are mass production units. To be honest I’m just in the process of getting rid of the customer but it’ll be nice to present some facts about the shortcomings to the owner,I’ll find out more about the sizing. I know what you mean about people will always care more when it’s their own project, I suspect this maybe a prime example.

-

I’ve noticed these things seem very popular these days and, when you think about it, there’s quite a clever idea hatching there. One of my customers (a large holiday site) has several new “eco” lodges which are fitted with Mitsubishi units which are supplying the under floor heating and the hot water. The lodges are all built to the modern building specs and when the sun comes out through the large windows are lovely and warm. I can also say the ASHP system does a fantastic job of heating them up. But a couple of issues. 1. They do like a fair amount of power for an “eco” system, is this normal? They have compared with the older Scandinavian lodges on site (heated with electric heaters and an unvented cylinder with immersion) and they seem to use as much power if not a bit more. 2. The older ones are coming of age and they are starting to break down quite often, control cards, compressors, you know all the expensive stuff. One of the bean counters on site worked out due to these problems and the install / repair costs that they are more expensive to run. Is this normal and people are fitting them because they have a green reputation? The reliability issues maybe due to the proximity to the sea perhaps? They don’t look that corroded but salt can get in everywhere. I’m genuinely interested on peoples views as my customer is starting to get suspicious of these things as being a gimmick and I would like to give him a balanced view. cheers

-

Shame, a very useful little bonus to have especially if you ever set up a workshop because secondhand 3 phase kit is not only better it is cheaper as well. For my 3 phase I have a rather nice but bloody heavy old generator.

-

Thermal store powered by Rayburn to radiators.

MrTrevithick replied to MrTrevithick's topic in Boilers & Hot Water Tanks

The TS has an expansion tank via the loop from the Rayburn (it has a bleeder just for the top of the TS as well), after a bit of experimentation and advice from a couple of aged plumbers the gravity loop system came about. The problem was that the TS and Rayburn were on the same level so how to make a gravity feed work? But the solution works fine but I had to mount the expansion/header tank a lot higher than the system, which it is. I’m just in the process of building a control panel to run the central heating and include the fail safes but the gravity feed system takes care of itself rather well. I’ve done the unvented system course and work on heating and ventilation systems in supermarkets etc so am aware of the dangers of unvented hence I went down the vented TS route, plus it works well with the off grid nature of the place. -

Thermal store powered by Rayburn to radiators.

MrTrevithick replied to MrTrevithick's topic in Boilers & Hot Water Tanks

Pump power is from the solar system, that’s another subject. -

Thermal store powered by Rayburn to radiators.

MrTrevithick replied to MrTrevithick's topic in Boilers & Hot Water Tanks

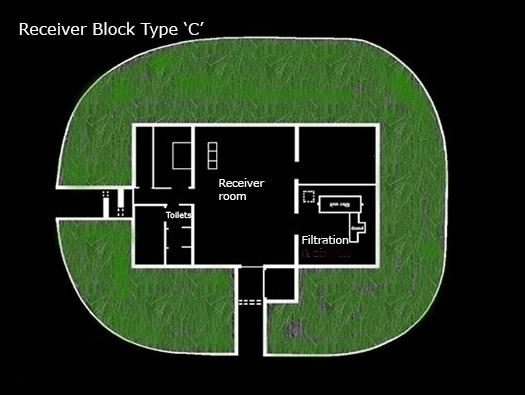

Oh ceiling height is 8’ except the small receiver room which is 10’. -

Thermal store powered by Rayburn to radiators.

MrTrevithick replied to MrTrevithick's topic in Boilers & Hot Water Tanks

Ah, the thermal mass is the concrete (18” thick walls and roof and 4‘-5’ thick in the floors) the whole place is then clad in 1”-2” thick bitumen cement and buried so the earth/aggregate thickness is between 6’-20’ thick. I have blown air heaters feeding through the original cable ducting about 3’ under the floor which keeps things ticking over at 18 dec C (a system used by the MOS when building underground factories) but I would like a second option to heat hence the radiators. The original system (now out of commission) was a 9kw blown air system at ceiling height and the original radar equipment in the place would have produced a lot of heat (it had a HV substation to feed it all due to power distribution distances). The walls and floor hold a steady temperature. I can’t line out the building as it will destroy the original features but it was designed to hold sensitive equipment so it is very dry (bit too dry tbh). I was thinking along the lines of a flow and return pipe and tap off to the rads so I maybe going the right way. On the plan the Rayburn is by the dotted square in the filtration room and the thermal store is in the room below, I’ll get my measuring stick out but the big receiver room is 7 mtr by 5.8 mtr to give you an idea of scale. -

After a bit of advice here regarding best radiator feed system to install on my system. Let me explain (sitting comfortably then I’ll begin), my system is completely off grid but I don’t like being cold and I have a reasonable size property to heat (about the size of a 3 bed bungalow with very good thermal mass and insulation). I have original cast iron radiators around the place of which there will be about 9 maybe 10 in total, the system doesn’t have to react quickly due to the thermal mass but it does have to disperse the heat from the Rayburn (solid fuel) as it has a high capacity boiler and can heat the thermal store (300ltr) rather quickly. The Rayburn is feeding the thermal store via a gravity feed system (all on a single floor but it works well). I’ve installed a flow and return from the thermal store (pumped) but have only just got out into the main property so I was wondering what system of pipe work to install ? The place is rather solidly built and I’d rather not drill holes I don’t have to. The main pipe work is 28mm copper surface mounted with brass mountings (not that that makes a lot of difference) so I was also wondering at what length do you start to think about expansion loops or the modern equivalent? Cheers.

-

Valves for cast iron radiators.

MrTrevithick replied to MrTrevithick's topic in Central Heating (Radiators)

Cheersmedear -

Hello. Can anyone recommend a supplier for original type valves to fit my ex hospital radiators, the feed pipe is 22mm copper. cheers

-

That would be telling, no point in living in a bunker and not keeping a few secrets ?

-

Very nice. Sounds as we are in similar situations. Off grid is a lot easier these days (I lived off grid in a house in 1993 and that was very generator based) and the technology is getting cheaper. I have, what an estate agent would call, “distant sea views” which in Cornwall can vanish most days. The view from my garden.

-

Some people think I’m bonkers but the way the world is going they are starting to change their minds, or that’s what they say to my face ?.