ggc

Members-

Posts

46 -

Joined

-

Last visited

Everything posted by ggc

-

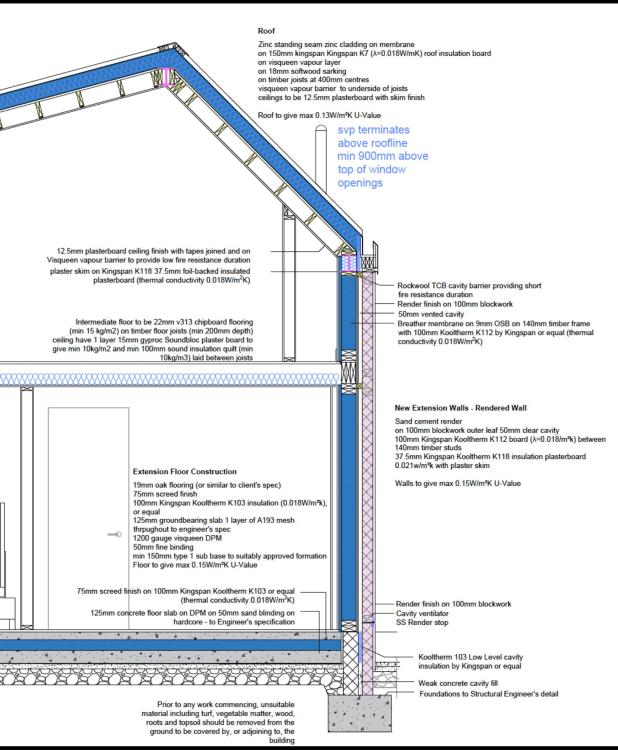

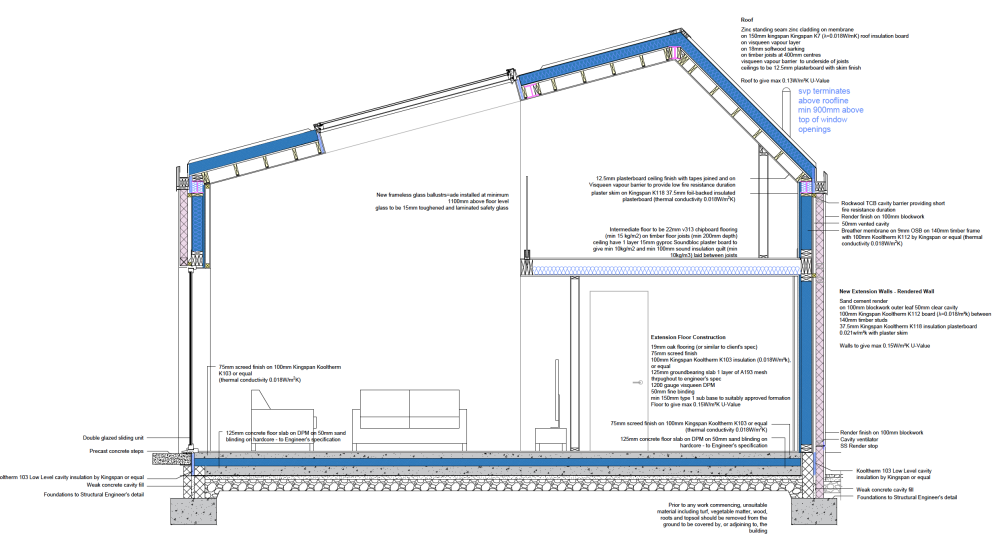

Thanks everyone for your input, makes for interesting reading, but my brain is well and truly hoovered out! For clarity, this is what we are working to……… Our SE and Architect have specified: 100mm Kooltherm Between 140mm studs/timbers In my layman’s mind, the electrics would run on the inside face of the insulation? (Reason for the 40mm cavity before the 37.5mm insulated plasterboard goes on)

-

It’s our first time build, where would we get that information please? We are following the SE’s submitted information, which was to use 100mm I guessed that it should be at the back, allowing space for the electrics, then the membrane over, followed by the plasterboard (which again is the insulted type) TIA 👍

-

Hi again Hive….. I think we are now pretty much ready to start the arduous task of installing our wall insulation. What I was wanting to ask is regarding the placement of the insulation between the timbers please…. Our timbers are 140mm wide, and we have to fit 100mm Kingspan Should our insulation be right at the back, almost touching the boards? Or further out, sitting just behind the plasterboard (when fitted) ? Many thanks

-

Having spent 20yrs working in sales in the motor trade, working with some very high end brands, I appreciate that attention to detail is of paramount importance. Nice to get some opinions that counter the liability argument. Verbal was always something that i adhere to, wysiwyg and all of that. As @Dave Jones says Third one’s a charm!

-

Folks, Please correct me if I am wrong, but should the actual window frame be attached to the fire stop? As you can see in this photo it is nicely tucked in behind the blockwork creating the check reveal? The builders left this at least 10mm Im preparing to compose an email to be sent to the glazing company, and want to have my terminologies correct. Pic shows the inside of where the sliding door now resides This is the same on every window, a minimum 10mm check reveal cheers

-

Well, we purchased one of these earlier today after watching a few YT videos Tested it on some offcuts that were stored in the garage after having that insulated. Gives a very clean cut, with virtually no mess created whatsoever. Probably going to knock up a jig of some sort to help speed up and give accurate and consistent sizes of insulation (as suggested by Robin Clevett) Wont get a start on it until next week 🤞

-

Thanks @Kelvin We aren’t finished with them by a long mile….. Our Crittall door turned up to be fitted, and it has been ordered opening outwards, not inwards like we had verbally requested to the sales chap. He fudged the order confirmation, and we never noticed! It just gets better doesn’t it 🤦🏻♂️

-

I think I love you for giving me a glimmer of hope of getting this mess sorted out

-

So we had a ‘small’ delivery of insulation arrive yesterday Took Mrs GGC and I the best part of two hours to move it from the driveway where it was offloaded , into the build to keep it safe and allow access. Anyway 😁 As we have a touch of OCD regarding neatness and accuracy…. Whats the best diy’ers method of cutting this with minimal waste, and the best odds of accuracy without creating badly angled cuts creating less insulation against the wall timbers please ?

-

No technical drawings ever supplied to us by the installers. We didn’t know this was a ‘thing’ that we would have either have been supplied with to check, or should have asked for Payment for these was made in full before fitting 10% of invoice price to get them to come and measure up after the price was agreed. 50% of outstanding balance paid to place the order Final 50% of outstanding balance paid 10 days before install, so they have our money! Maybe a saving grace that it was all paid on a C/Card? Im embarrassed to say there will be a lot of naivety on our part as this is our first dip in the self build swimming pool. I know we will learn by our mistakes, and learn what questions to ask and what documentation to ask for - shame it costs money to make these mistakes

-

-

-

Thanks for your opinions Craig. We are so keen to just get the project finished , that further delays and hassles just don’t seem worth the fight. The Renderer, see’s no issues with doing the job to a high standard, and there was none of the “sucking through his teeth “ noises when we had a meeting on site earlier today. We just aren’t the kind of people to creat a fuss , to ultimately end up getting a few grand back. But I suppose that’s kind of foolish on our part, If deep down we aren’t happy with the install! The product, however, is lovely, and we are happy with the actual units. Even though we have had them finally fitted Are we really in a position to keep noising on about the miss-measuring? 🤷🏻♂️

-

So….. The glazing company blame the builders for having the fire stop incorrectly positioned. And stand their ground that everything is good. They have now fitted the angled window above the sliding glass, and had removed the frame to pack with timber ply, to make it a snug fit. The chap we are going to use for the rendering job today said the glazing company have mis measured. Looks like we are sucking it up, but I will piss n moan with the other issue at hand ( an incorrectly ordered door) that is still not resolved and looks like at best is 6 weeks away

-

El-cheapo laser gave out the same result as their expensive professional tool (to my surprise too) Tilt & Turn is to be re fitted

-

Well, We have a meeting on site with the sales representative on Monday am We have asked for his measurements to be sent across to us to see what he has taken prior to the meeting. hopefully it’ll show how the error has occurred, and who to point the finger at for the discrepancy ! Mrs GGC has an incredible eye for detail, and this just isn’t to her standards, and isn’t going to allow her to sleep at night knowing things just aren’t how we visioned it sadly. (dunno how she puts up with me though 😉) They plan on getting the glazing units fitted up there next week, only two weeks after the promised install date, and about 3 weeks after this all started. I don’t know how they will get SWMBO to swallow this.

-

-

A lot of it has similar 30mm gaps! Even a large Tilt/Turn window looks to be off plumb by around 7mm at the bottom (measured with a laser level) The issue is, it wasn’t the cheapest quote , we paid for a bespoke service and tbh this isn’t meeting our expectations That angled window is 4m across, I haven’t worked out the area of glass that’s missing, but it’s more the aesthetic of the finish, as we wanted to hide some of the frame behind the block work (which the builders have created the recess to allow) If I swallow this, it means we have more render making the it look not as we wanted.

-

That’s the kind of answer I expected, though didn’t want to hear! 😂🤦🏻♂️ In your professional opinion, what’s my options? Am I being unreasonable asking them to manufacture it again?

-

Thanks for the positivity Took us a while to finalise what we wanted We started off 5 years ago thinking of going partially underground, but the incredible costs soon changed our mind! 😂 Popped a mezzanine in to give us extra space needed (tbh it is almost 50% bigger in sq/m compared to the bungalow, almost rude for me to call it an extension 😂)

-

Yes, similar gaps around some of the rest of the installed windows, which as you say are filled with expanding foam. TBH not what I was expecting (nothing ever is, is it) One of the windows expanding foam appears to be deteriorating already after maybe being in situ for almost a fortnight, could it be UV degradation? (Thought I’d taken a picture of it, but haven’t)

-

Thanks for your answer. I had read that 5-10mm would be an acceptable tolerance. Having watched some of Robin Clevit’s videos, he seems to need to “persuade” units into position as tolerances are that close.

-

Hello folks. We recently started our glazing install on our new extension. The glazing company hasn’t been back for a week or so due to an error with a door that has been ordered incorrectly (50/50 blame with us and the company I feel). Anyway, we are having quite a large shaped, fixed window installed above a sliding door This was measured by the Sales chap and one of the senior installers. There is a 30mm gap all around the frame where it (is supposed to) fit against the timbers & masonry. Is this really an acceptable tolerance for a bespoke measured measured job? Opinions gladly accepted They haven’t yet fitted the glazing to the frame. We we’re under the impression that the glazing frame should sit in behind the block work, giving a slimmer sight line, then attaching to the timber frame? Thanks in advance for opinions This I feel is just the tip of the iceberg on a badly measured job, or am I being picky?

-

Hi folks….. We have been long term lurkers on here before saying hi, before we start looking for solutions and asking silly questions with obvious answers! We are building an extension to a parents bungalow, to allow us to move in with them and be present during their twilight years. We are nicely underway, having had agreed with our main contractors to build the main structure to watertight , bar the glazing. We are about 3 months behind schedule, but that’s due to inexperience our end , figuring it out, researching, and making sure our part is done properly to completion. Anyway, just a quick “Hi” before you get bored of us asking stupid stuff that’s possibly been asked a hundred times before . Thanks in advance for your patience 😂 Here’s how we sit so far