NandM

Members-

Posts

133 -

Joined

-

Last visited

Personal Information

-

Location

Birmingham

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

NandM's Achievements

Regular Member (4/5)

4

Reputation

-

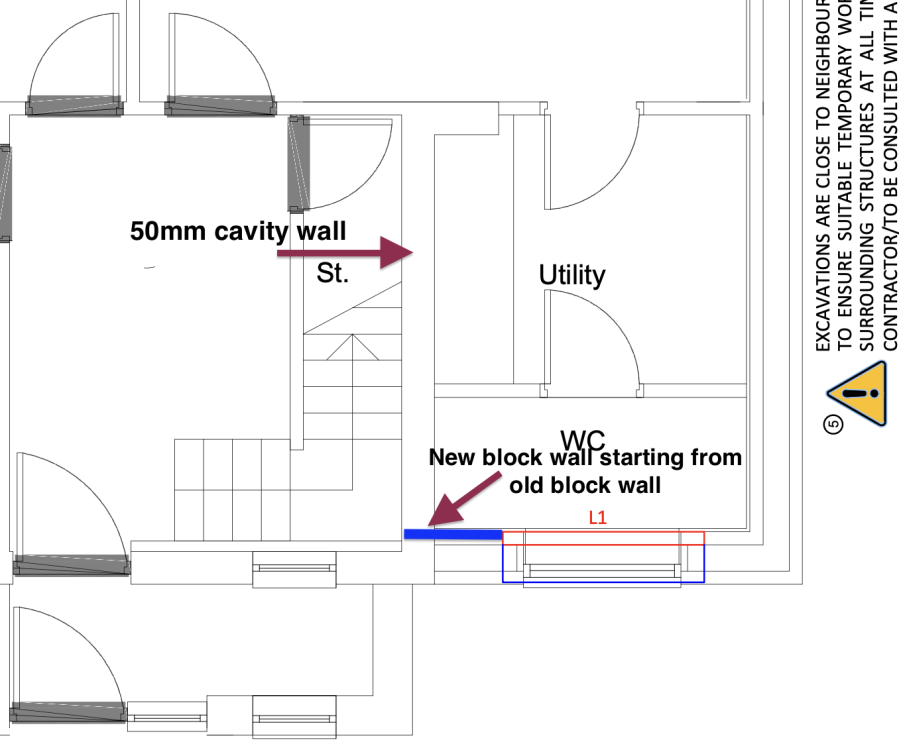

As part of our proposed extension work, a current external cavity wall will become an internal wall. The current brick wall will have a 100mm slit to act as a thermal break, but I will still have a approx 4m length of cavity that is still "connected" to the outside. Do you see this causing any issues with heat loss? I can wet plaster both sides to help with airtightness - but I really don't want to add insulation to the walls on both sides (although I could fill with eps beads). The one idea I have in mind is to start the new block work from the old block work by having an approx. 250mm opening down the entire side of the wall and joining the two. This will result in a separation between the" internal" cavity and the external one. There are two challenges I see here: 1) with the 250mm opening, could it be done from bottom up without the need for any lintels. Google tells me this should be OK. Otherwise, we could do it top down. 2) the new block that will connect to the old would have to use whatever the current foundation depth is - at least for 150mm of the block. Would this be a problem?

-

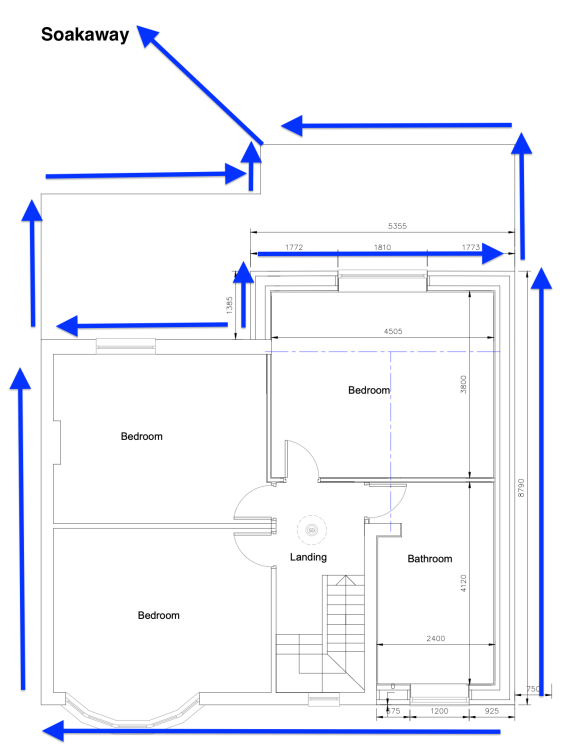

I'm finally about to start the groundwork (yay!) and am thinking about the best way to get the rainwater to the soak away. I'm hoping my simple design by routing all the pipes to one outlet would work? In effect the pitched and dormer roof to route down to the flat roof pipes on ground floor and from there to one gulley and then to the soak away at a distance of 5m, and under 4m of patio.

-

Why do the timbers need to sit proud and would 10mm be enough?

-

And are they left in place as the concrete is poured? (I'm hoping to (finally) start my extension in coming months)

-

What are those "mars bars"?

-

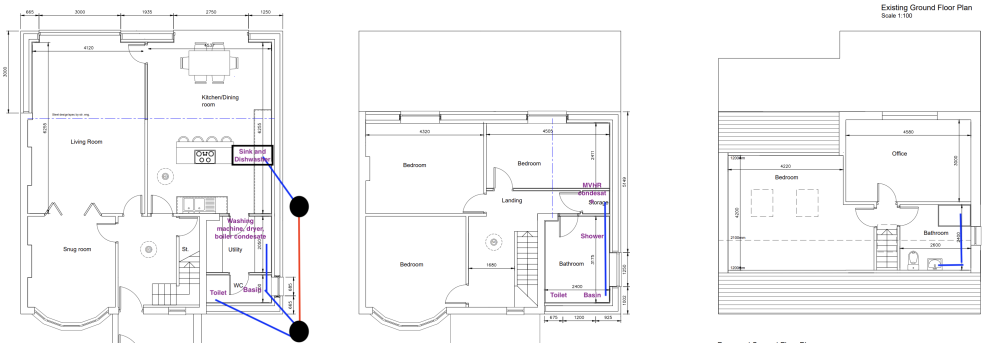

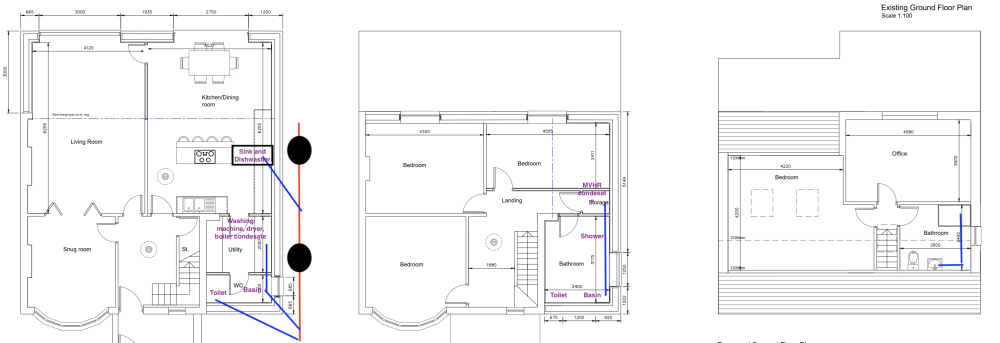

I think just laziness on my part! I'll bury it and keep the pipe overground for now as per the blue line.

-

I wasn't planning to bury the mdpe underground to start as I have a run of around 65m to the front garden. Current temporary plan is to follow the hedge up the garden and then through the back of the garage and into the main inspection chamber at the front of the house. Once we have the new sewers put in as part of the house extension, I could route underground like the blue line and have the mdpe terminate into a 110mm pipe underground.....and bury the station. But I need everything working before the demolition starts.

-

Above ground sewage stations seem to come at a premium, so I'm wondering if I can use a below ground one above, or even partially underground to save on the digging. The bathroom I'm adding to the garden room is currently about 30cm above ground level - I could probably raise this another 10-15cm internally. I've seen some of the underground stations that have the inlet very close to the bottom - so if I have the drop, then what's stopping me from using one of these above ground? e.g. clickity and click

-

(Hopefully) a simple drainage design - but help always needed!

NandM replied to NandM's topic in Waste & Sewerage

I had my first trader (bricky) over yesterday and he mentioned there may be difficulty in getting an inspection chamber in place because of the available space. Between the outside wall and the neighbours wall will be our alley way of approx 850mm width. I've had a look through Document H and couldn't find anything specifically about IC and how close they can be to a wall. I was also looking at Diagram 8 and for clarity, as the distance of the new drainage will be less than 1m from the footing, how much lower does the new drainage than the footing? This also seems contradict some posting I've seen that say the footing should at least go to the lowest part of the drain pipe. -

(Hopefully) a simple drainage design - but help always needed!

NandM replied to NandM's topic in Waste & Sewerage

That's brilliant - thank you! -

(Hopefully) a simple drainage design - but help always needed!

NandM replied to NandM's topic in Waste & Sewerage

According to this, I'll need two rodding points, one in the loft and one on ground floor. -

(Hopefully) a simple drainage design - but help always needed!

NandM replied to NandM's topic in Waste & Sewerage

@ToughButterCup - what about treslous? So I've moved the I/C's - but I'm wondering if it would be possible for one water drain for the ground floor, from the kitchen to the basin in the WC. -

residential soakaway for extension flat roof

NandM replied to johnhenstock83's topic in Waste & Sewerage

@johnhenstock83 - did you managed to find the answer to this? -

For our extension work, I've designed it so all the bathrooms are above one another and on the same side, to help simply the drainage. With regard to the toilets - what's the recommendation within having multiple toilets into one waste pipe? Something to avoid...or should be fine? The drains on the outside will be in our alley way, but I'm really unsure about how many inspection chambers and rodding points. At the end of the front garden there is currently a fairly large inspection chamber - it would be great if I could get rid of this in the new design so I can make better use of the drive.

-

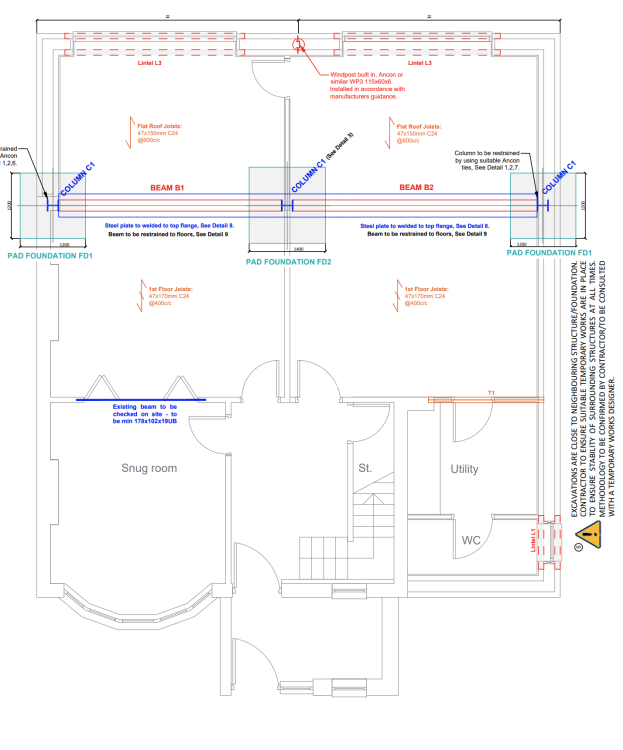

My plans have dragged on a bit...but I'm hopeful to start this Spring. I've received the SE drawings for extension we have planned and have a query about the beam design for the ground floor. The current design is single beams with a plate as required. The left hand beam will support the original cavity walls, which have a 50mm cavity, and a bedroom upstairs. The beam on the right will support a new wall that will go all two floors up to form the wall for the dormer. This will have a 200mm cavity. Just thinking about making the build easier and minimising cold bridging - would it be better to have two single beams, especially for the one on the right?