PaddyP

Members-

Posts

24 -

Joined

-

Last visited

Everything posted by PaddyP

-

ICF and Insulated Raft Junction

PaddyP replied to PaddyP's topic in Insulated Concrete Formwork (ICF)

Thanks @Russell griffiths will have a look for a Triton stockist in Ireland as that's where I am based. I cannot find any peel and stick membranes online. Could you direct me to any brands? Will also contact ICF supplier. Thanks a million. -

ICF and Insulated Raft Junction

PaddyP replied to PaddyP's topic in Insulated Concrete Formwork (ICF)

Would this maybe do the trick as an extra layer of protection ? https://www.screwfix.com/p/bostik-flashband-grey-10m-x-150mm/55009 -

ICF and Insulated Raft Junction

PaddyP replied to PaddyP's topic in Insulated Concrete Formwork (ICF)

Thank you all very much for the replies. Yes @FM2015all roofing and guttering is on and windows in. Just awaiting external cladding and flashing to arrive and install. Thanks @Russell griffithswill have a look into the triton and see if any local builder providers have a stick on membrane available. Sounds good @saveasteadingcheap and cheerful! Is it blackjack suitable for painting directly on to eps? -

@JamesP your ceiling looks fantastic! Love the exposed timber. Real attention to detail required there! Hi @JohnMo thanks a million for those pictures. Great to see that the flat bit is barely noticable. Thank you everyone for their help. I will speak with the structural engineer and see what they reckon. Has anyone used scissors trusses? While the flat bit is barely noticeable I still would like to avoid it if I can without too much additional cost and effort.

-

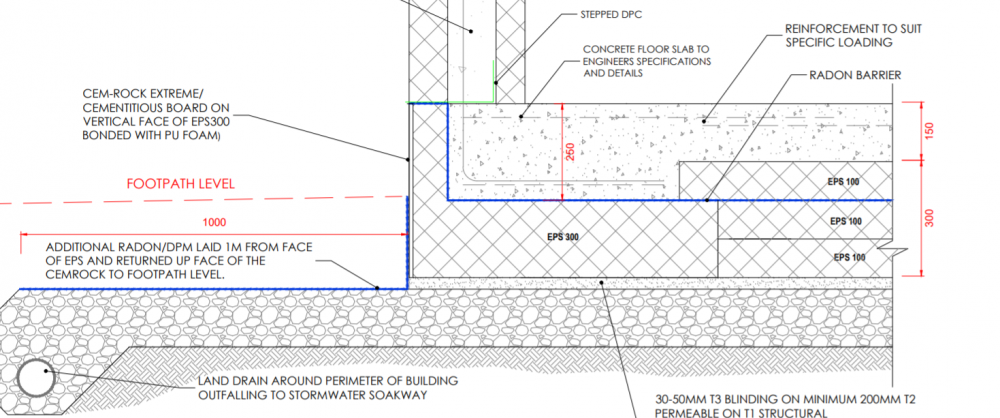

Hi all, I am currently building a house using a Kore insulated raft foundation and 350mm Amvic Passicve ICF block. Since the ICF walls have been completed we have noticed patches of damp on the slab where the ICF wall meets the floor. These damp patches are located randomly around the perimeter and are not located just under windows so doesn't appear to be an issue with sills. The raft foundation is our finished floor and will be polished in the coming weeks. After contacting Kore their solution to solve this problem and prevent further issues is to install a basecoat and seal the connection this way. However, the house will battened and clad in corrugated metal so this solution is not of much use to me. From what I unfortunately only now see, this seems to be a fairly common issue. We have not yet completed our external cladding and flashings yet so perhaps that will solve the problem by directing water away from the junction and I am worrying prematurely. However, if this does not fix the problem it will be much more difficult to fix after cladding so would like to go overkill now if necessary. Detail below was used during construction. Stepped DPC detailed was not installed due to the starter bars. In hindsight a hydrophilic tape/waterstop should have been added but unfortunately too late for that now. Has anyone come across a product solution to this issue? or can think of a

-

New build floorplans - opinions welcome

PaddyP replied to Indy's topic in New House & Self Build Design

Well I'm more of a lurker than a poster around here I think this thread encapsulates all the good that this forum has to offer. Lots of valuable feedback here for any self builder to look over. @ETC@etc has provided two excellent designs. While I prefer the first one the one above seems to fit more to your style and is a marked improvement from the architects draft. -

Hi Russell, thank you very much for your feedback. That sounds like an excellent option using the Web joists. Does it need to be sheeted in OSB on the outside or just a felt? It will be a slated roof. Hi Peter, I have just received planning so just trying to get an idea of things in my head. I will definitely have a structural engineer on board. The scissors truss looks a good option. Hi @Ralph that looks a great space. From your picture it is difficult to see the flat piece at all.

-

Hi there I hope you are all keeping well. I am currently looking the roof design of our house. We are trying to achieve a vaulted ceiling in the open plan area. This area measure 5m wide x 12m long. We are trying to achieve a full height pointed apex and on the ceiling and not have a flat piece at the top. The picture below shows the finish we are trying to achieve. However, most people appear to have a flat bit at the apex rather than a point. In many cases this is to hide MVHR pipes. We will also have MVHR in the build so wondering is there an alternative? How can we achieve full height apex ceiling and still have space for services? Some options I have come across are scissors trusses and parallel chord trusses. Are these viable options or am I barking up the wrong tree? Any opinions links, pictures etc are greatly appreciated!

-

Nudura One series variation

PaddyP replied to LadyBuilder's topic in Insulated Concrete Formwork (ICF)

I got the Amvic 350 block directly from Amvic. I am in Ireland myself and got it directly from their factory to my site. This was last summer so not sure what their current situation is like. I dealt with Alan and Cillian in Amvic, both were very helpful. -

Nudura One series variation

PaddyP replied to LadyBuilder's topic in Insulated Concrete Formwork (ICF)

I used the Amvic Passive 350mm block. This gives a u-value of 0.15. It is 100mm insulation 150mm concrete 100mm insulation. Would recommend the Amvic system but not haven't used any others to compare against. -

Hi all, We are just finishing off the roof structure here and hit a bit of a bump in the road. The house is split into two blocks each with a 5° monopitch roof. We had wanted to put a metal standing seam roof on however had struggled to find a supplier that would a. give a guarantee at 5° b. could roll 20 metre lengths required for the roof c. would not cost the moon and stars. I eventually did find a supplier but now unfortunately this has fallen through so am exploring other options. The roof structure is Thermoroof insulated panels, 50mm battens for ventilation and decked in 18mm OSB. The options I appear to have are as follows: Fibreglass/ GRP: always appears to be highly recommended on the forum here. From research only appears to be as good as the installer. Where I am in the South East of Ireland not the most popular choice and installers are lacking so not my first choice. Single Ply Membrane: mechanically fixed to the roof. Soprema and Trocal are some of the brands used by installers here. One Trocal installer visited the site and said he spends most of his time on repairs these days which has sent alarm bells ringing. EPDM Rubber Roofing: Firestone is the only real option for this here. Single sheet glued down appears to be fairly highly regarded with a 25 year warranty and expected lifespan Of 50 years plus. To me the Firestone EPDM appears to be a clear winner. Reasonable price, long lifespan and reasonably robust. Is there anything I'm missing here? Is there downfalls to EPDM I'm not aware of or any horror stories? Thank you very much for your help!

-

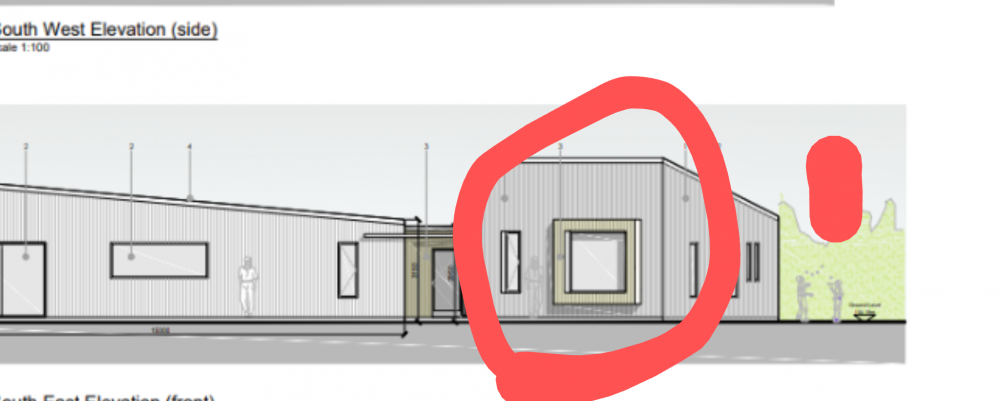

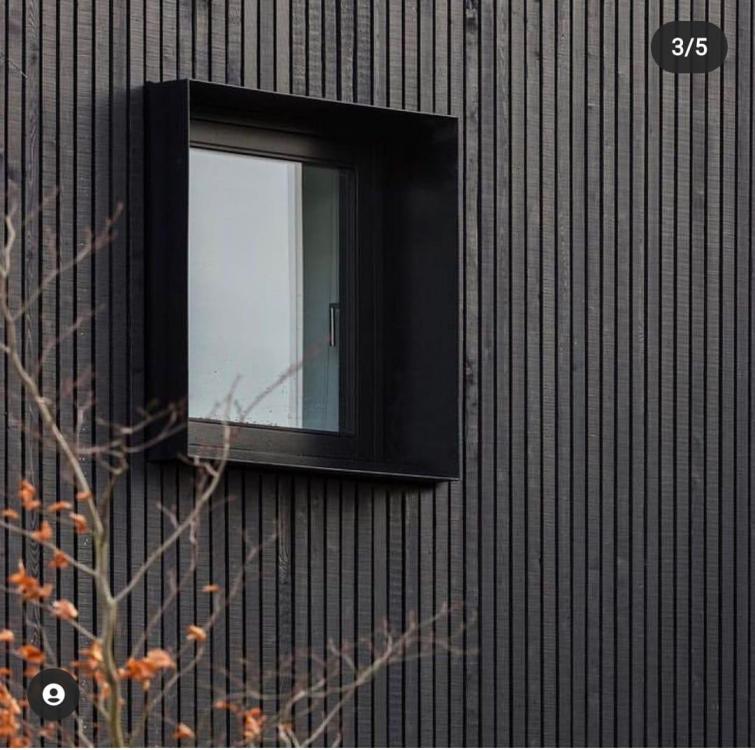

Hi @ToughButterCup yes it's a metal reveal I'm looking for. I agree it looks fantastic when done well. The difficulty I appear to be having is nobody seems to want to take responsibility for it. As it's off standard and it's falling between trades. As you can see in the picture below we just have one window with this feature so while not essential would be a nice feature and would like to keep it.

-

Hi all, I am having a little bit of trouble with the external window reveal of one of our windows. We want to extend this further and create an overhang like in the picture below. The house is ICF and to be clad in corrugated metal. Keeping the windows watertight is a major concern of mine. We have come to a solution for all other windows except this one. Has anyone done something similar and would be willing to share their solution? Or have an idea who I should approach? Would this be something for a specialist metal fabricator? All the best, I hope

-

New Member from Cork Ireland building ICF House

PaddyP replied to Blynchy's topic in Introduce Yourself

Hi Blynchy, I'm in Ireland myself and building with Amvic ICF and Thermoroof panels are being delivered this morning. Can definitely recommend the KORE insulated raft and Amvic ICF. Will let you know how the Thermoroof goes! -

3 d renders , how much and any good ?

PaddyP replied to Ronan 1's topic in New House & Self Build Design

I have gotten 3d imaging for two houses from the website Fiverr. It is a free lancing website so their are hundreds of different people providing the service. Have a look through their reviews, portfolio's and pricing to see which one best suits your needs. Most will include 2-3 revisions and changes of things that they didn't get right the first time. I paid about £120 each time for 8-10 external render images. -

Thank you very much for your replies it is much appreciated. @Mr PunterPunter thank you for those suggestions. I will have a look into those zipped seam systems. @Russell griffithsGriffiths I would only have a 5 meter run of gutter at the end with a corner window at one corner which makes the engineer a bit apprehensive about the downpipe situation . Our ICF walls are to be clad in corrugated metal so we are hoping to hide any downpipes behind the metal cladding.

-

Hi all, Trying to reach a decision on the best way to remove rain water from two large monopitch roofs. The initial plan from the design stage had been for a metal standing seam roof with all the water coming off at the end. However our engineer has concerns with this: 1. Rainwater from a 100m2 of roof coming to one section would be too much. 2. Not many suppliers are willing to stand over metal roofs at a 5 degree pitch which we have. Some of the solutions proposed for problem 1so far have been to hide a pitched roof behind the parapet wall or including 3/4 box gutters at intervals going across the roof to reduce the amount of water reaching the bottom downpipes. I am wondering does anyone who have any solutions for this problem? Problem 2 seems easily fixed with an EPDM membrane or another flat roof product. Is metal definitely out of the question at 5 degrees. I would prefer metal due to the longer guarantees. I have attached elevations below to give you an idea of the roof. All the best and thanks in advance, Patrick Furraleigh House North Elevations.pdf

-

Thank you both very much for the replies. For many of the windows it wouldn't be much of an issue and I wouldn't mind the windows moving slightly to fit the blocks. However for some windows I would like to be more exact. For example we have a large window that is to be flush with the kitchen counter and if it was possible to cut the blocks to achieve this that would be fantastic.

-

Hi all, Possibly a very dim question here but one I can't seem to find the answer to anywhere. When building with ICF blocks are you limited in the heights you can place windows? For example: I want to place a window 900mm from the ground. My ICF blocks are 400mm in height. Does my window have to be placed at 800mm, 1200mm or can the blocks be cut? Maybe this is a system dependant question but interested to hear is this a problem or am I making problems were none exist. All the best, Paddy

-

Would you consider swapping your WC with the pantry? They appear to be a similar size and your pantry would then be beside your kitchen. Could also enter the WC through the utility if you did not want a door directly into your dining area.

-

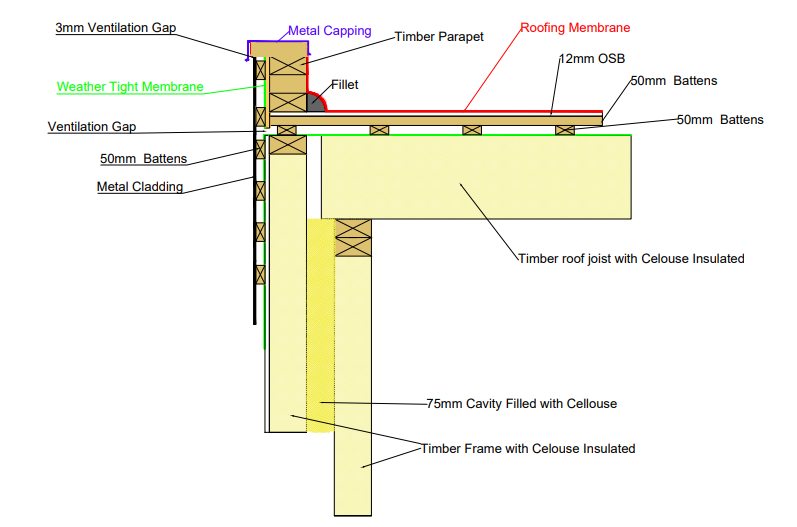

Hi all, Thank you all very much for your helpful replies they are very much appreciated. I am a complete novice to this so I may be explaining things wrong but try to learn and will answer questions to the best of my knowledge. Don't worry I have a builder and engineer to fall back on so I won't be allowed go too far wrong am eager to be involved and would like to learn! It's great to hear that people have been able to successfully DIY a rubber roof. Attention to detail seems to be the main thing. I will have plenty of help for installation so that should jhelp greatly. I am eager to use cellulose in the roof mainly due to the cost benefits of it. At the moment it is coming in at about a third of the cost of PIR. As long as a cold roof is ventilated properly I would assume there should be no problem with it? Is the heat loss significant enough between a warm and cold roof to warrant a change? I think calling it a flat roof was probably a bit off. There is actually a pitch of about 4 degrees on the roof so this should take care of that much. The fall of 4 degrees is over 15 metres so I presume that is enough to carry away the water? Thank you very much for your feedback on the membrane. Thankfully the roof isn't due to be done for a while yet. We are just clearing the site at the moment for probably wont be done until March/ April time. For applying the roof I would be planning to follow the approach here https://www.youtube.com/watch?v=YVU3ejUa2sA&t=211s. This involves using a water based adhesive in the middle and a contact type adhesive at the upstands/ edges. Would this be an ok approach? I plan to bring the membrane over the parapet so that detail will be updated thank you for pointing it out. The cladding on the wall is vertical. Would it best to counterbatten the wall to assist with ventilation as mentioned elsewhere? Would I need to double the OSB? Nobody will be one the roof so I thought that would be strong enough. I am eager to use cellulose in the roof so felt a cold roof was best to achieve this. Thanks to all again for their help and replies hopefully I have helped answer some of the questions posed. All the best, Patrick

-

Hi all, Just looking for a bit of advice. After trawling through the forums and consulting with my builder relatives/ engineer we have settled on a rubber roof membrane. I will be doing the bulk of the building myself with my builder relatives and am trying to save money wherever possible. I have received back some ridiculous quotes so far for the installation of a rubber membrane, with some in excess of £100+ per m2. My roof is a very straight forward rectangle with parapet walls and no roof lights or other tricky details so I see no reason why I shouldn't be able to do it myself. I am looking at using a single sheet system such as Firestone or ClassicBond. Does anyone have any experience with either of these products? Firestone seems to be the most popular however the price of ClassicBond is very attractive. I have also attached our proposed roof build up if anyone had any feedback or advice it would be much appreciated. All the best and thanks for your help, Patrick

-

Hi all, We have just received planning permission in the South East of Ireland for a modern mono-pitched home. I am planning to do the majority of the work myself with my father in law. While I have no building experience he is a carpenter and builder by trade so his wealth of knowledge should see us through. At the moment we plan to have a Kore insulated foundation with underfloor heating incorporated as part of the floor. While we are not going for a passive house we do plan to have very high insulation and air tightness levels. We plan on stick building the timber frame on site and pumping the walls and roof with cellulose insulation. The roof itself has a very shallow mono-pitch of 5 degrees and so far have received ridiculous quotes for rubber membrane installation so we are hoping to do that ourselves also. For the outside we are going to clad the whole house in black corrugated metal. I have found this forum a wealth of knowledge so far and will hopefully be able to tap into it further and share my own experience as we progress. All the best, P