SimonD

Members-

Posts

1926 -

Joined

-

Last visited

-

Days Won

10

SimonD last won the day on March 3

SimonD had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

SimonD's Achievements

Advanced Member (5/5)

946

Reputation

-

It's funny the cash in hand malarkey. From the other side, it's so common for me to be asked by customers if I'll do the job cash in hand. I never do jobs cash in hand because they're the ones that show up the nature of the customer - they want cheap cash in hand deals but at the same time also want all the regulatory sign off and building regulations notifications is incredible. And they want all the back-up as and when suits them. As a trade, you need your wits about you to choose your customers wisely too!

-

ASHP outdoor unit heating pump Q

SimonD replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

I think there are 2 options here. 1. is to calculate the press loss in each loop to correctly determine the index circuit and then see if you have enough residual head at the heat pump. My suspicion is you probably do. If you wanted to do this then as you have the flow rates already, you might already have the pressure loss figures from the design documentation somewhere? If not, the pressure loss can be calculated from the flow rates. It's a bit laborious. 2. is you just take a punt and remove the buffer and additional pump and see what happens! I think you'll probably be okay, we won't know for sure until you get it up and running. Then there remains the question as to why they installed a buffer in the first place. Was it: - just a mindless design that plonked it in there; - to do with a calculated or feared pressure loss issue; - to do with system volume as your system doesn't hold the minimum volume per minimum kW output of the heat pump; - to actually buffer excess output from the heat pump as it's oversized? I would be worth doing a system volume calculation to make sure you have sufficient volume. That way if you don't, you could plumb in the buffer as a volumiser and this will save you a headache and repipe if you just cut it out and then have issues. The last thing worth doing is to understand your house heat loss co-efficient - this is how much heat your house loses per Kelvin change in outdoor temperature. To do this we need your calculated heat loss at the required design outdoor temperature and design indoor temperature difference. This figure is useful because we can then find out at what outdoor temperature the heat pump will reach minimum modulation to understand where it might start to cycle and then understand if the buffer was put in for this reason, although I doubt this because the buffer is so small.- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

ASHP outdoor unit heating pump Q

SimonD replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

This is critical. Your index circuit basically means the sum of the sections of your heating system that adds up to the greatest pressure loss. For every meter that your heating water flows through a pipe is loses pressure. To know whether the pump can deal with this, we need to know the maximum pressure it has to overcome and at what flow rate. If you look at your specification chart, you have a max flow rate of 1205l/h and at this flow rate, if you look at your chart, it gives a residual head of just over 4m head. To know if the pump will be okay with this, you need to know if the circuit that has the greatest pressure loss is less than 4m head. Do you have a circuit diagram or do you know how your heating system is plumbed?- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

One of the bits of my house remaining is a hallway where towards the end we have a doorway that was there with the original house. The hallway is wider than the doorway. The doorway is in a single skin brick wall right next to a brick pier. The wall is structural in the sense that on top of the wall I have a wall plate upon which there are doubled up bearers of 45 x 175 standing on edge along the top of the wall to which joist hangers are fixed for all the 1st floor flooring. It doesn't take any roof loads but there is a stud wall above. These double bearers span the whole width of the doorway extending to the end of the house in one direction and about 500-750mm the other side. Originally I thought this doorway would be fine but now we've got to plastering stage I've decided it all closes up the doorway too much and it just feels too narrow. The original lintel is a concrete one that I know extends about 200mm into the pier and about 150mm to the other side. It's the other side at 150mm where I need to open out the doorway. I was first wondering if I could use an SE's suggestion of doubled up studs anchored to the wall, but then I don't really gain much although maybe just 50-75mm would make all the difference, who knows. Are there, for example any metal brackets that can be fixed to the wall that would support the lintel? Or is it possible that with the doubled up bearers I might not actually need this lintel any more as this was the old exterior wall holding up a concrete tiled roof? This is probably not that straight forward, but does anyone have any suggestions as I really don't fancy the work required to take out this lintel and replace - and yes, I know I should have thought about it sooner 🙄 Thank you!

-

ASHP outdoor unit heating pump Q

SimonD replied to BotusBuild's topic in Air Source Heat Pumps (ASHP)

So what we need to know is which exact model do you have - what is its power output? Do you know the index circuit pressure loss for your heating system? And what is the property heat load?- 19 replies

-

- vaillant

- arotherm plus

-

(and 1 more)

Tagged with:

-

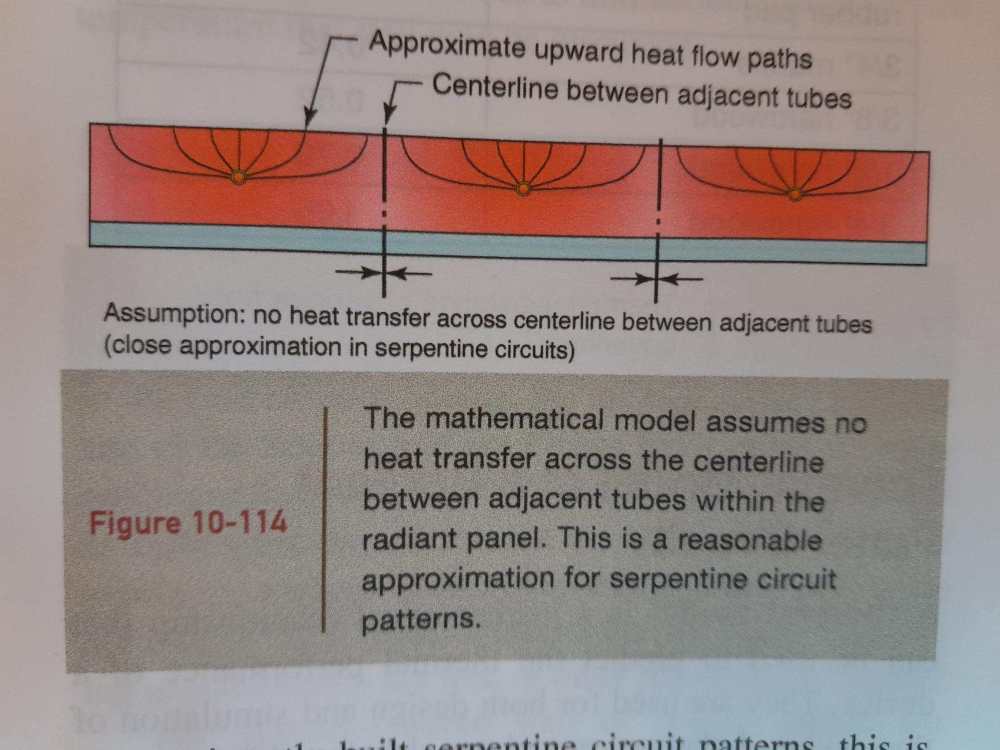

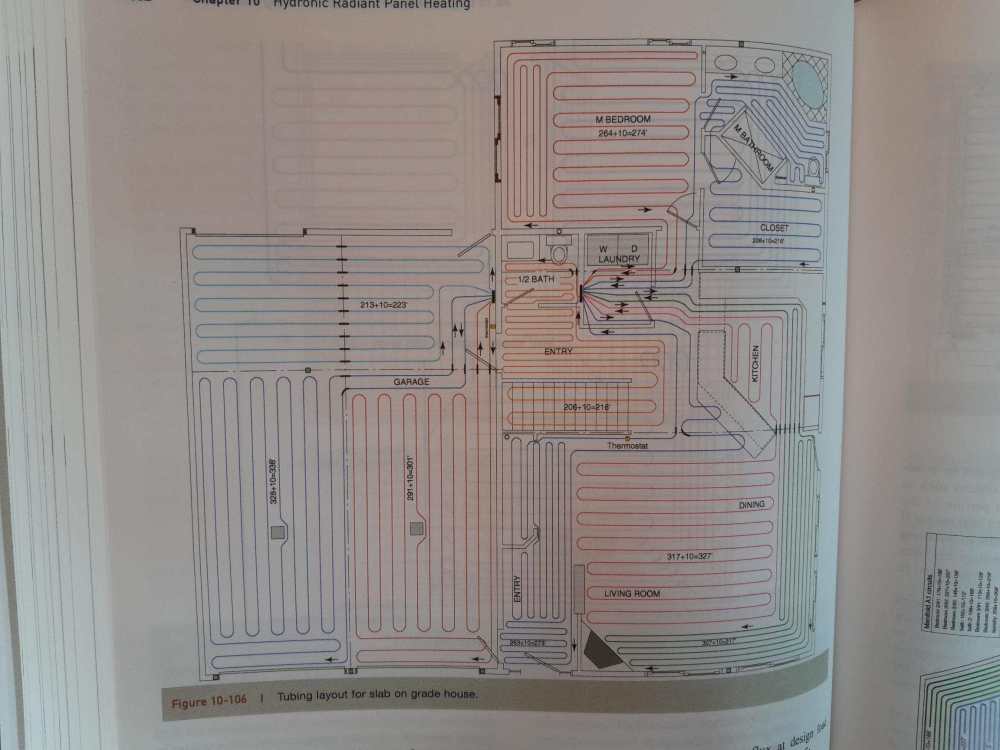

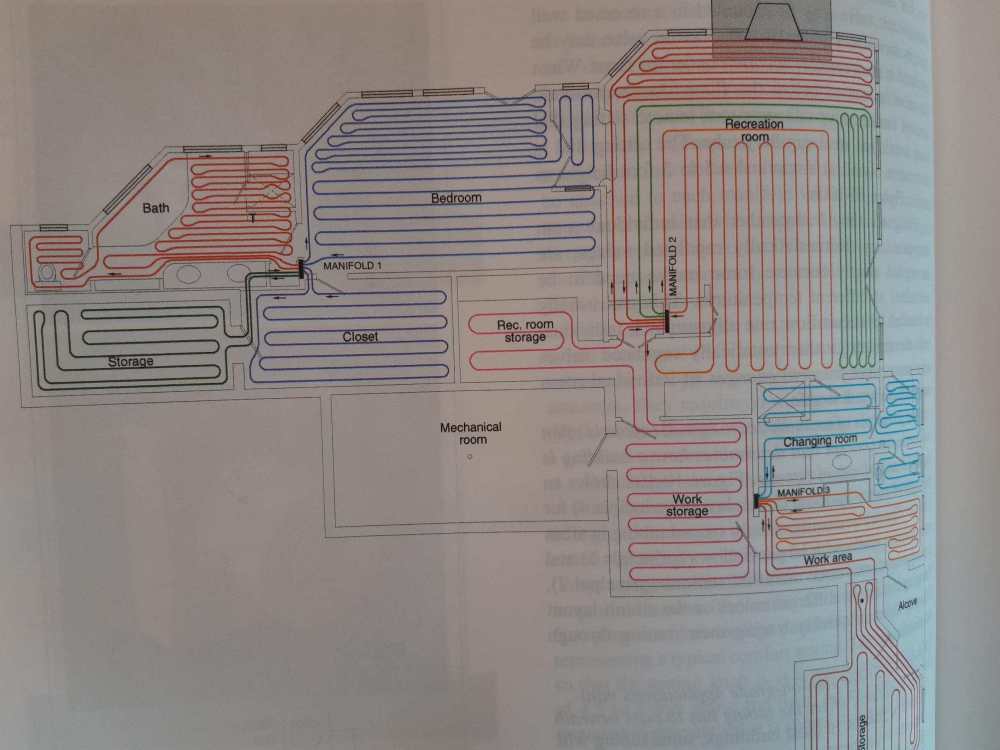

Yes, so the paper manuals and guides I used for all my basic training are (no great thermodynamics knowledge needed with these, thankfully 🙂). The underfloor heating design has lots of tables to referencing outputs and floor temps etc. and dovetails in the the CIBSE industry guide for sizing and designing heating system. The low temp guide has lots of easy win nomographs which can save a lot of time for ballpark figures: This links into the above question. As the output of the floor depends on pipe spacing, it seems weird that we can just discount that in design and just not worry about it? Output depends on the balance of several factors, including spacing flow rates and flow temperature all together. The calculation regarding the output of buried pipes is actually quite complex calculation, simplified here in this image: If you have significant transfer across the centre lines, then you're going to have problems with the balance of system output. Here is some images from a much more detailed hydronic books, which illustrate correctly varying the pipe spacing - look for example at where the spacing it closer at certain external parts of the rooms (this is also covered in the ufh design book above but to a much lesser detail: These and the illustration of pipe centre lines are from Modern Hydronic Heating & Cooling by John Siegenthaler. It has a very detailed section of UFH design, but the book costs nearly £100 and it's all in imperial so you need a way of looking up the metric constants etc. for SI unit conversion. HTH

-

UFH Design - LoopCAD, Heatpunk,Spreadsheets & Copilot

SimonD replied to Adrock's topic in Underfloor Heating

That's a good point. You always need to know the full load the pipework is going to carry as well as pump curve and heat pump drop offs. I always get these from manufacturer technical as part of a design if it's a new product for me. So to illustrate in @Adrock's situation. Lets for arguments sake say the output of the heat pump is 6.5kW in DHW mode. That same 22mm pipe, still assuming a total length of 30m (which it probably won't be as this pipework includes the section to the ufh manifold) This time I've adjusted water temperature to a conservative 40C. The figures are: Pressure drop: 19.69 kPa (2.01 meters head) Flow rate: 0.311 l/s Velocity: 0.97 m/s So the velocity is almost spot on for copper design purposes and you've got a doubling of the pressure drop, but if there's sufficient residual head at the pump, this should be no problem at all. My calcs include a 20% addition for fittings and if I remove fittings it drops to 16.40 kPa (1.67 meters head). If you used 25mm MLCP you could probably do the run without many fittings at all. So even in this scenario, providing there is sufficient residual head, which their should be from a decent heat pump as the pumps are now getting pretty big, even with DHW you're very well within a comfort zone. If I take this to 28mm. Pressure Drop: 5.69 kPa (0.58 m head) Flow rate: 0.311 l/s Velocity: 0.58 m/s So here, you're only just within the 0.5m/s velocity limit on dhw. As a real world example, I have one heat pump with a 6.5kW output at -5 installed with about 15m of 22mm polybutylene push-fit pit as the owner did not want to rip it all out and upgrade due to the extent of works required through the house. Yes, it's on the flow velocity limit of 1.2m/s on DHW but there are no issues at all with flow rates or function and efficiency is extremely good. The question is whether you want to incur the costs of 28mm pipework and a low flow velocity regime when for the vast majority of the time flow requirements are going to be nowhere near. -

water pipes underfloor: conflicting advice: help sought.

SimonD replied to saveasteading's topic in Barn Conversions

Sorry, that's difficult to say. I've got accounts with a few companies that have websites but they don't necessarily list the products on the site, you've got to call them to order the stuff in. Some of these are trade only. But most decent plumbers merchants, and especially renewable wholesalers will be able to cater for this as it's becoming increasingly common for this pipe to be used for heat pump installations. The water regs website is good, but it's not the complete reference. My reference is this dog-eared manual that's been seconded to drinks mat duty on occasion that you get when you complete your WRAS qualifications. -

water pipes underfloor: conflicting advice: help sought.

SimonD replied to saveasteading's topic in Barn Conversions

Nothing wrong with exceeding expectations. It should be the norm really, shouldn't it? Glad to hear you've found your solution -

water pipes underfloor: conflicting advice: help sought.

SimonD replied to saveasteading's topic in Barn Conversions

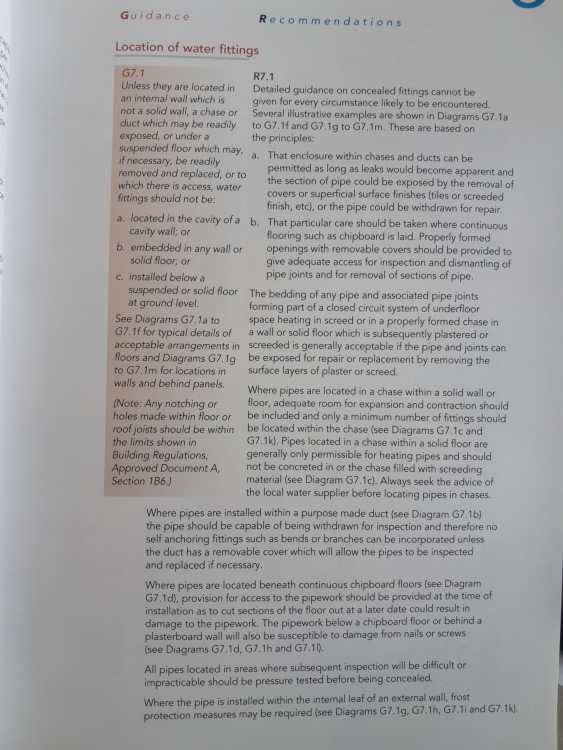

TBH, I don't really care whether the BCO will let something past, I care about the quality of the installation and how it can be serviced over time when necessary. This is explicitly allowed for in the regs guidance: "the bedding of any pipe and associated pipe joints in a closed system of underfloor space heating....in screed.....is generally acceptable if the pipes...etc. can be exposed by removing layers of screed. Pipe located in chase within a a solid floor are only generally permitted with heating pipes and should not be concreted in." So like I said the regs apply to pipe as fittings and they should not be installed below a solid floor at ground level - because we're talking about potable water and domestic hot water. If it's a new build then it takes a matter on minutes to install ducted pipework. The marginal cost is so small, there's no point even arguing about it. Which is what bemuses me here. A few months ago a customer of mine phone me about a leak where they'd got some emergency plumber in who had to dig out a whole load of concrete floor and in the end they had to get the original build in to take up a load more. This is a multi-million pound house. If they'd done it properly to begin with, the pipe could have been whipped out of the duct and replaced. Sh1t does happen. -

UFH Design - LoopCAD, Heatpunk,Spreadsheets & Copilot

SimonD replied to Adrock's topic in Underfloor Heating

Assuming that you have full load to your manifold and therefore lets say 30m from heat pump to manifold and 22mm copper pipe - assuming 5C delta T- will give you: Pressure drop of 9kPA (.92 Meters head) Flow rate of 0.191l/s (or approx 0.688m3/h) And a velocity of 0.61m/s This includes a 20% allowance for fittings and a water temperature of 35C (viscosity of water changes with temperature). With pipe sizing you don't really want to drop your velocity below the industry figure of 0.5m/s due to risk of debris settling in the pipework and you would do this if you used 28mm or 32mm MLCP. You could use 25 or 26mm MLCP and have roughly the same results as with the 22mm copper. This means that you could get away with 22mm copper and just make sure the nearly 1m head is okay with the rest of your system index circuit pressure drop and the pump residual head. It's so common for installers to think you need much bigger pipes. I've recently installed a 9kW heat pump (that can put out over 10kW) with a 25m long header to the house using 32mm MLCP and that's currently running a scop of 5.4. In this instance my header pressure drop is 1.1m head and flow rate of 0.8m/s well within the limits of the max 1 or 1.2 m/s maximum depending on which brand of MLCP used. Index circuit is just over 2m head with a pump with residual of 7m so really no problems at all. In your case, at 4kW the figures for 32mm MLCP would be: Velocity 0.36m/s Pressure drop 2.59kPa So even with 22mm copper you have some headroom if the heat pump can output more than 4kW and it'll save you a good few quid v 28mm. -

water pipes underfloor: conflicting advice: help sought.

SimonD replied to saveasteading's topic in Barn Conversions

Nick, the term "fitting" includes pipes! What I posted up includes reference to pipe too! FFS, I give up....🙄 -

water pipes underfloor: conflicting advice: help sought.

SimonD replied to saveasteading's topic in Barn Conversions

-

water pipes underfloor: conflicting advice: help sought.

SimonD replied to saveasteading's topic in Barn Conversions

So this is what I said earlier, which you may have missed: First, you need to confirm exactly what barrier pipe they're referring to. Is it the MPDE barrier pipe that is design for COLD water services, or are they merely referring to Hep20 or Polybutylene push-fit pipe. As a distinction for you. PEX is the push-fit pipe that has memory and it's a pain in the arse to work with. Polybutylene is the lay-flat type of pipe that has less memory, but memory still. Second, MDPE service pipes, including the barrier versions are design for cold supplier. Their specifications usually state: based upon a 50 year design life at 20˚C. Any increase above 20˚C will result in a reduction in the maximum allowable operating pressure or lifetime or possibly both. Polyethylene pipe systems should not be operated above 60˚C. Your intended purpose as I understand it is to carry domestic hot water in your kitchen. Therefore MDPE Barrier pipe is completely unsuitable for this. PEX and Polybutylene as well and MLCP (whether PEX or Pert) are tested to over 100C and are designed for hot water.