Jamie McNaught

Members-

Posts

24 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Jamie McNaught's Achievements

Member (3/5)

2

Reputation

-

Timber for SIPS - Regularised vs specified width

Jamie McNaught replied to Jamie McNaught's topic in Building Materials

They might, but that'd be a hell of a hassle - they're a 150 mile round trip - I somewhat naively assumed they would be standard widths.... I am not sure whether I am talking about the SIP's or timber in general. I've spoken to the SIP company and they've said 70mm is fine as long as sufficient expanding glue is used and the beam is directly centred. -

Timber for SIPS - Regularised vs specified width

Jamie McNaught posted a topic in Building Materials

Hi all, So I've just discovered the complexities of getting timber to specific width. Needing to get locating and sole plates for some 100mm and 150mm sips (11mm OSB, 78 or 128mm PIR insulation) Everywhere I look, timber is measured as 75, 125 (locating plate) or 100, 150 (base plates) but is actually regularised, so about 5mm less than this. e.g: https://www.travisperkins.co.uk/treated-timber/c16-kiln-dried-regularised-sawn-treated-timber-47mm-x-75mm/p/9000044445 SIP manufacturer is fine with 75/125mm for the 78/128 insulation SIP as expanding glue will bridge most of this, but obviously not 70/120mm. And you can't put a 100mm SIP on a 95mm base plate - there is not enough OSB supported apparently. Am I missing something here? Can anyone point to C16 / C24 tanalised timber that is actually the full width? Many thanks, J -

Hi @Gus Potter, thanks for the details reply and ideas. Sorry about the slow response, I've been afk for the last week. What would be the reason for the different look - is this to bring it in on budget (we are almost there with SIPS) or some other reason? I don't really want to start investigating alternatives, worring about insulation issues etc when we know that SIPs are perfectly capable (and quick to put up!). This is a very different approach - what are the benefits of this versus SIP's? Have you got any links to off the shelf pricing to try and compare the costs? With the flitch beam being bolted to the roof SIP, would this not reduce the danger of this? I've no idea I have to say, just going on the SIP companies recomendation (although *still* waiting on an actual calc + dimensions). We have, but this is cost prohibitive and it's size + weight might become an issue. My understanding was it would be as heavy as a flitch plate but bigger. In all honesty I've not investigated much as the SIP manufacturer was not keen and price seemed high. Given time is an issue, I'd prefer not to hold out for a mis measured one. Ok, I'm confused - I suspect I am missing the obvious here. In what way is welding a top & bottom plate onto a steel portal not just making an RSJ goalpost? And would this not have all the problems with cold bridging that the RSJ would? This was the original plan for the RSJ - it would form a ledge to rest the SIPS on - albeit we'd not get torsion as it's stupidly overspec'd. Drilling would be an issue, but it comes pre-drilled at 400mm centres, so a piece of structural timber would be bolted on. This is why we were originally going with an off the shelf RSJ - too overspected to twist. There are already holes in the web - a 2x6 would be bolted to this and then the SIP bolted to that.

-

SIP manufacturer has suggested a flitch beam - this should provide much of the strength of the RSJ without the cold bridging / cost and can be hung from the sips. Any thoughts?

-

Thanks for the reply Gus, I really appreciate it - please bear with me on this.... I'm really keen for your input on an alternative to RSJ's. Contrary to my earlier comment, I do agree with you that the door frame, attached to the roof will not pull/deflect outwards at the top - the roof when assembled is strong enough absorb this. The issue I think we currently have is that we somehow need to span the roof either left to right (using the side sip walls) or front to back (using the rear SIP wall and RSJ or an alternative) (the original plan). I'm aware the side walls (in a front to back span) will transfer roof weight to the ground - calcs I've done for RSJ don't take this into account as that's complex to do and I was aiming for a 'worst case' scenario. Options: span left to right - the span is 5.2 -> 5.4 (building width) to support the roof. SuperSIPs (http://www.supersips.uk.com/index_htm_files/span table.jpg) insist on 2x5 (x1), 2x6 (x2) & 2x5 (x1) for 4.8m, without a roof light. With a roof light + 5.4m span we don't have details - trying to get this. We could use glulam as a replacement for (or addition to) the 2x6, but as the standard height for glulam is 225mm v's 150mm SIP thickeness means we lose the flat ceiling. We'd need a minimum of 3 spans of this with 1.2m sips inbetween. 3 Gluman 90x225x6m is £465 (https://www.bucklandtimber.co.uk/glulam-beam-cost-calculator/). This seems expensive and results in a ceiling with two joists - we are tight on ceiling height. And I've no idea if it works! span front to back - this needs something for the beams&sips to rest on at the front. Original plan was the RSJ. I'm not sure what the alternative is. Possibly Glulam again, but we're back into worries about downwards deflection affecting the operation of the bifolds - I know we can get a gluman that can handle this but no idea of specs - I'm working on calcs. Additionally, the glulam will need support at each side - the SIPS are not strong enough for this point load at the front - so probably kiln dried 2x6's or some other post. This then gives us the goalpost config we had before with the roof load transfering down in the same way as the RSJ, albeit the glulam is lighter than RSJ (half?). At which point we're back to looking at pads to transfer the weight - albeit not as much. Steel goalpost RSJ is £570 and I know it will work / not deflect. Yes, it technically needs larger foundations, but the load at the feet would not be much more than Glumam. If we try to span left to right, we have a huge span that I don't know how to handle. So, am I missing some alternative solution? Am I too worried about the span left to right? (will get back with options for spanning 5.4m in SIPs as soon as manufacturer gets back to me).

-

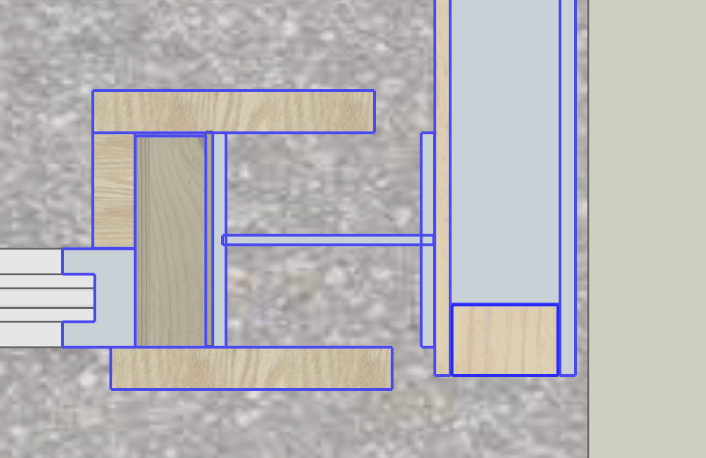

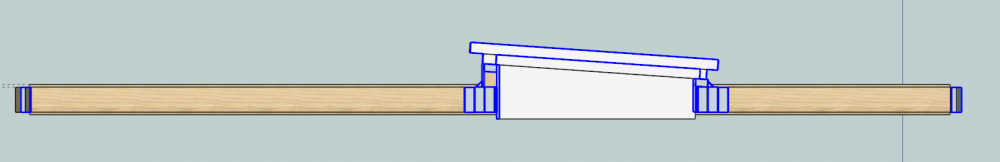

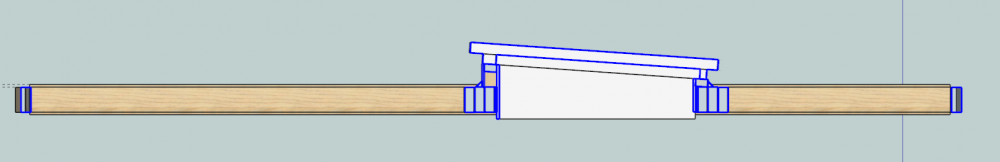

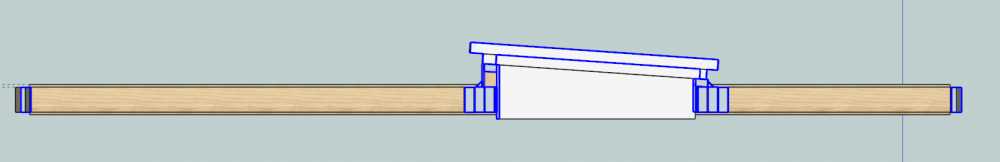

I've been using this, so choices are a bit limited. If you can point to another tool or resource that'd be good - I know little about OC / UB / box sections. https://shop.mrbeam.co.uk/ work in progress pillar cladding plan below - pine 2x6 spacer to bifold frame + oak cladding. There will probably be another pine strip to hold the inner oak in place (which will be longer). The outer oak pannel will be secured to the battons for the cedar cladding (with Tyvek house wrap behind it. The rest of the ibeam volume would be filled with PIR/celotex. Pretty much same detail for cross beam.

-

deleted

-

Looks amazing! Are you blogging your build? Or just crashing each night on the sofa!

-

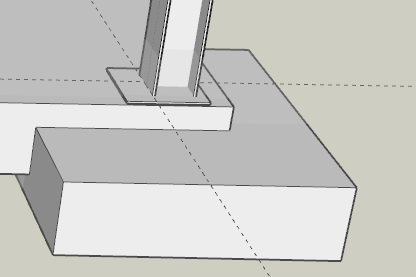

I might be adding confusion as the feet are not acutally in that diagram - they're not 'under concrete'. See below. I'm imagining shuttering it, including the 100m slab and pouring in one to ensure it forms a single slab with no weak joins. Hopefully, the lower pads wont overflow due to weight of concrete pushing down from the 100mm slab (like this Could the bolts for RSJ's be put in while concrete is wet using some form of template to ensure they all line up for when actually attaching the pillars when contrete is dry? Or would you drill and stick them in with resin afterwards?

-

Something like this? 100mm slab (inc 1x A393) 300mm at edge 1000x1000x300mm pads to support RSJ (inc 2x A393) all cast in a single pour hopefully?

-

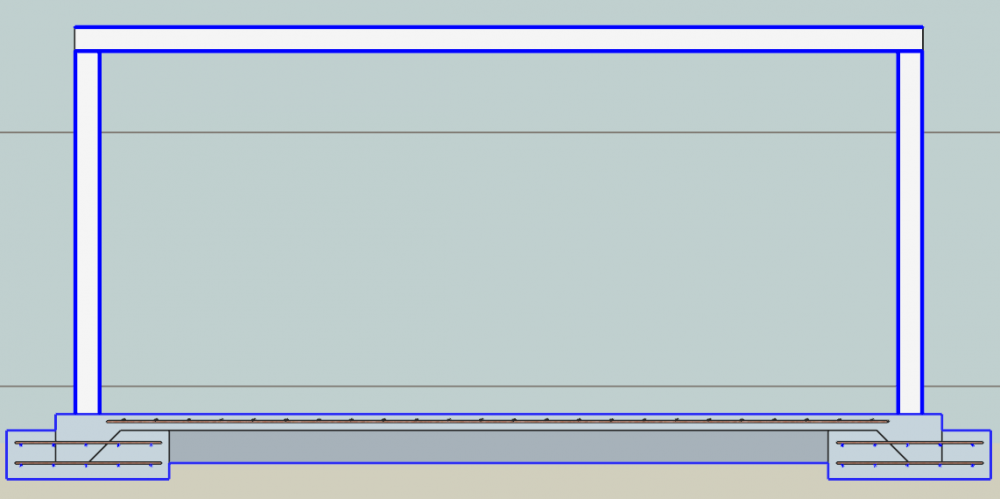

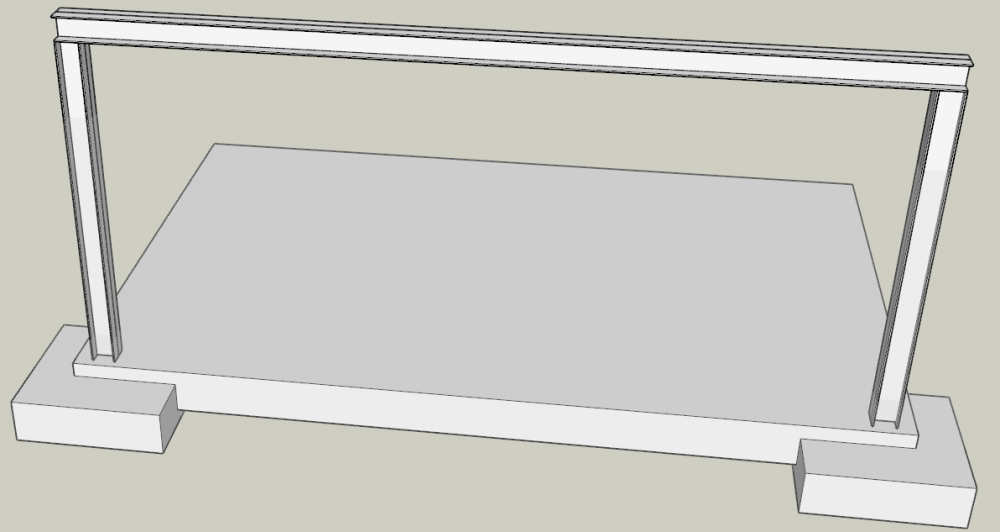

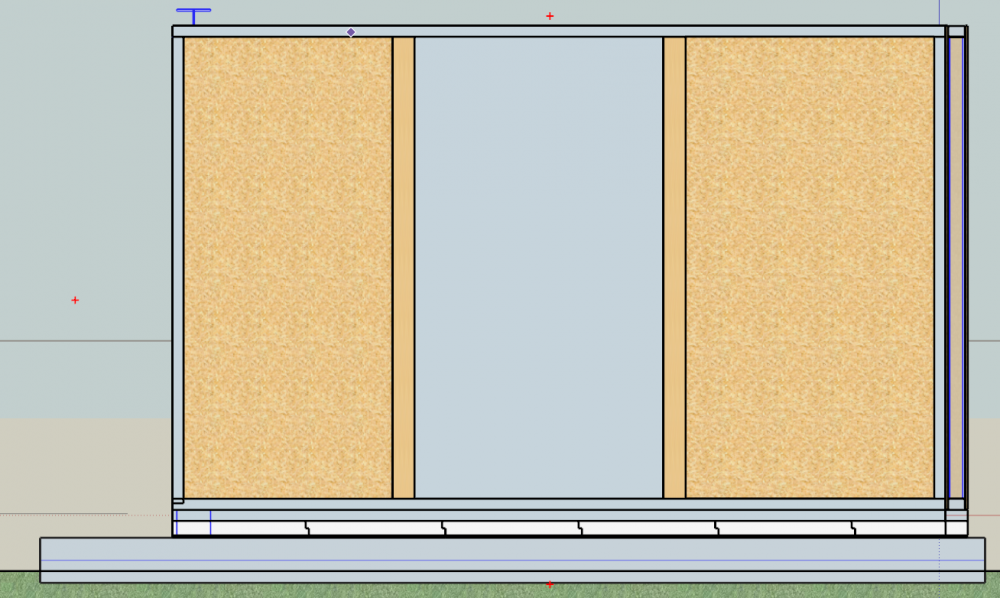

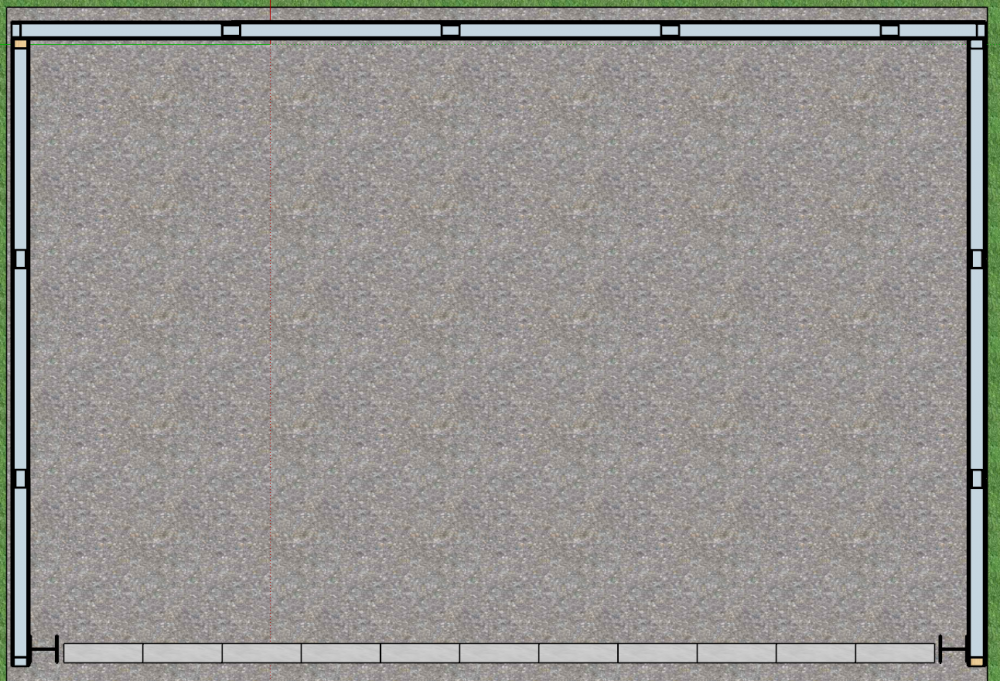

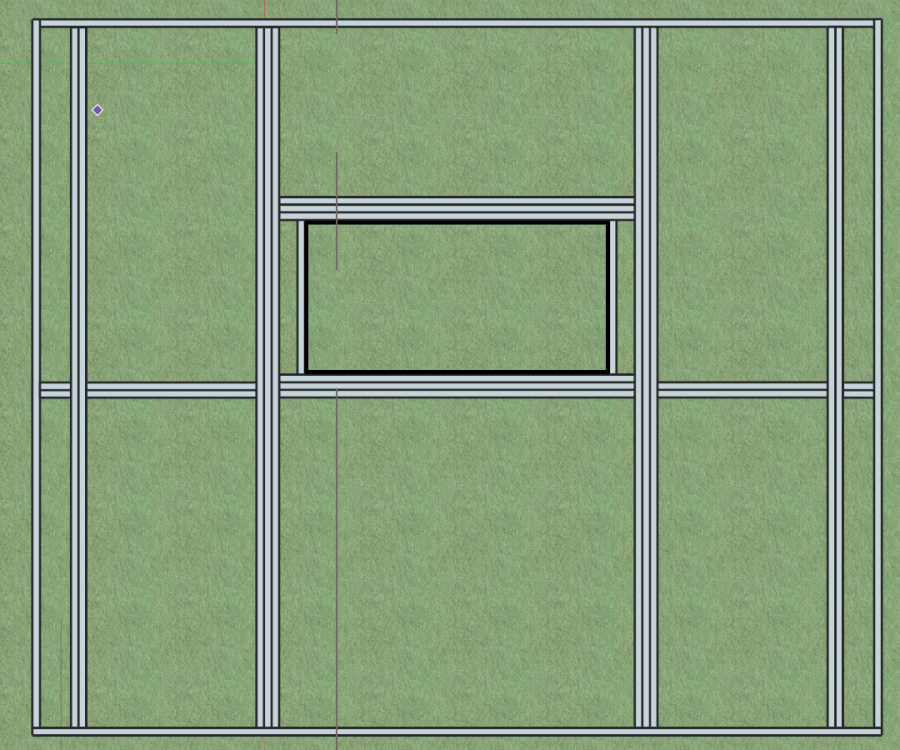

The reason for going with bifolds is to maximize the opening from office to garden - while lift and slide doors are great, we'd at best get a 66% opening v's bifolds at about 90%. I'm pretty certain they are top hung, but waiting to hear back from manufacturer (they don't put their install instructions online so difficult to tell). However, if they are bottom hung, when the doors are open, you will have a huge amount of lateral force pulling forward out of the building? ie still a need for a strong support? I agree without the bifolds there is less load on the opening... but this is still a 4.8m opening and investigations thus far have highlighted that this can't really be done in wood (we looked into Oak, but no manufacturer wanted to talk about deflection on 4.8m). Catnics are max 4.8m, so we could perhaps switch to that by reducing the span (https://catnic.com/products/lintels/bhd100), but that is still £400 - the goalpost RSJ is £650. It's a SIP build - 100mm walls, 150mm roof, celotex floor on slab. Walls are build on 100x65 Marmox Thermoblock, 2x4 sole plate, 2x3 sip inserts. Roof is secured to sips all the way round with bolts as 400mm and to i-beam. See below for more details. Walls End Elevation 100mm SIPs, sip splines, 2x3 ends. Walls - Plan View. 100mm sips, SIP splines and 2x3 Timber ends to surround. Roof - End Elevation - Sectional View through middle of Skylight Roof - Plan view Timber is 2x5, except where three beams where is is 2x5, 2x6, 2x5. All gaps are filled with 150mm SIP's exept skylight in centre. The hope was that we could float it, however, the long term plan is it will tie into an extension (there is now plans to "knock it down") so possibly making sure it doesn't float but actually stays put is the way forward.

-

Thanks, soil descriptions are helpful. I'm assuming if it hits the ground and crumbles (rather than remaining as a flat blob) then it's more sandy than clay? By edge foundation do you mean strip foundation or do you mean thick edge on the raft? I thought raft / slabs were ideal when on clay and strip foundations were going to get prohibitively expensive? (Appologies, to this point I've ignored foundations and got on with the design of the stuff above ground). Yes, looking at the cost of A393 this doesn't seem like a huge cost. Would including this below the RSJ's have the affect of reducing sheering issues with the load fron the RSJ's on the slab? I'll try to knock up a more detailed slab drawing - builder wants to show this to an SE now.

-

Yes, I appreciate all of this is "best guess".... yours will be a lot better than mine! We're almost at the point where we could hand this to a structural engineer (i.e. we know the building weight, loads etc), but budget is very tight now - I'm trying to get this in below £10k (which I know I am going to miss, but hopefully not by much) with me doing most of the graft once we're out the ground. If anyone knows a SE who can provide rought calcs and isn't wanting to get super detailed I'd be grateful... I suspect (and I could be very wrong) that given the small weights and size, over specing the foundations etc is probably going to be cheaper than an SE doing super detailed calcs to try and save costs. It should be Permitted Development - height will be 2.4999m (when the roof light is retracted) ?

-

Thanks Mr Punter - afraid I don't know the soil type - I shall ask our builder who will lay the foundations. Is there an easy way to tell soil types? (Googling is not helping thus far). If I understand you correctly (soil type dependant), if the slab was thickened to 300mm with 2 layers of A393 mesh for areas of 1000mm x 1000mm with the RSJ base plates in the centre, then this would be sufficient? And yes, base plates will be added to the drawing (and the steelwork!).

-

This might be the wrong forum, but I think this is more specific to the foundations than the RSJ (but feel free to re-direct this to the RSJ forumn if needs be). We're building a garden office, but given the small size of the garden we want to include a 4.8m bifolds to try and keep as large an open space as possible. Rest is standard marmox+100mm sips+ cedar cladding. We've included a UC 152x152x30 goalpost to support the bifolds / avoid deflection and the rest of the SIP build. Calcs assume: 250kg doors 120kg oak rsk cladding + 50% of 908kg (SIP's, skylight, wood and snow - we're in Camb, but you never know) - the other 50% is assumed to be loaded on the rear wall (we've ignored loading on side walls). This gives a total load of appox 820kg on the beam, causing a deflection in the middle of 3.75mm which we'll compentate for with a timber slightly thiner in the middle to hang the bifolds from (I think - it might be 3.75mm is fine). So...... with 820kg load + 282kg goalposts can we put this onto a standard raft slab of 100mm conrete in centre and 300mm concrete at sides? Do we need to thicken this up / re-enforce at the goalpost feet, or is the weight really too trivial? Sketchup below - yes, I'm aware the feet are missing from the goalpost.