Alexx

Members-

Posts

47 -

Joined

-

Last visited

Everything posted by Alexx

-

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

ah, yep that would be impossible for me to track without microinverters or optimisers indeed. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

all victron documentation strongly discourage using optimisers as they would conflict with the MPPT own way of dealing with the panels. Also panels have 3 diodes from what I can see. As soon I have some data from the system I'll put my findings to confirm how this works in practice. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

from my understanding that can happen, but the likelihood is much smaller than an inverter or microinverter failing. multiplying the single inverter by 20 times will definitely increase the chances of getting a bad microinverter for sure, that is just statistic, If that is 0.01% rate, now you multiply that by 20, then now you start having 0.2% failure rate. I understand micro inverters have their place, like multiple different orientations, and if you have an AC coupled battery, besides that I struggle to see the benefits. In my case I ended up going all the way with additional MPPTs on the Victron system. I'm even considering in the near future making a solar fence, so I can just buy another £150 to £300 MPPT depending on the size and put several panels on it. That is the modularity I was after, but I'm definitely having to pay a fair bit more money for the privilege -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

definitely not, if a micro inverter goes bad, I need scaffolding and a lot of hassle to replace it. if my inverter fails, I can just replace it without having to touch the roof. To my point of view it makes no sense to touch micro inverters, they offer no benefit over a regular inverter. I would need AC coupled batteries to start with which is a completely no go for me. DC couple batteries like Gobel, Seplo, Fogstar and others are many times cheaper. Your point about multiple orientations would be the only benefit if I could not replicate the same with another system. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Do you have a link/URL for that by any chance? I'm not sure if I'm checking the correct document. Thanks! -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

ow, I missed that bit, thanks for pointing out! -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

I just realised I have another problem now. My energy meter was between the old inverter and my consumer unit, that was a system with no batteries. New inverter is in a garage about 20m away from the house on a sub consumer unit. My generation will only be realised when the house uses it, not when it is actually generated because I will store on the batteries a good portion of it, which will be accounted as generation once the house demands it or I export. This would not allow me to have a night tariff to charge my batteries as the FIT is only valid for energy generated from solar PV. I was thinking maybe I get a bi directional meter to subtract what I import overnight from what I export during other hours, but it seems I cannot do that due to FIT requiring all generation to come from solar (even if stored on batteries) as long it does not come from the grid. Not sure what to do -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

-

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

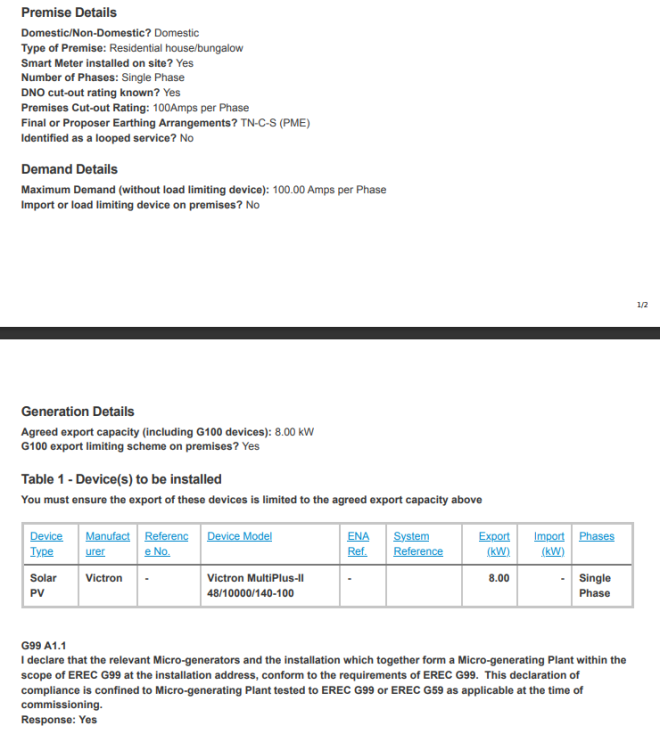

Great news, I've just got approval today from DNO and we have the 8kw approved. We used the document I mentioned earlier. Yay! -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

I moved into a house that had already a solar PV system in place, but it was old, not performing well, at best it generated 500w of the 2000. I didn't install or touched it, as soon I moved in I started converting the loft so the whole roof went, and with it all the existing solar PV array. Great to know, so the system will pay itself back much quicker this way. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

You may be right; I'm still gathering fragments of information and putting it all together so don't take what I'm saying as fact. I'll report back here once I make further progress. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Ah, so I could only export the excess as SEG then, not regular export like with Octopus? I'm trying to clarify with British Gas, they dodge questions all the time, I had to give them screen shots of Ofgem documentation for them to accept what they were meant to accept without questioning. Once I get this sorted, I'll move the FIT to another provider in hope I get better service. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

I have FIT from an existing installation for 2kw that was completely replaced with the Victron kit and panels. They will pay me 25% of my 8kw production, last time I had payment it was like 70p per kwh so that will definitely help with the pay back. I'm still trying to understand if I can get paid for generation and still export at 15p as well. I'm not 100% sure if I can mix and match. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Inverter can be G100 compliant, here is a document from Victron about it. I have installed pretty much everything already. DNO has been notified, they just keep dragging their feet. victron-g100-declaration-multi .pdf -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

It is expensive, it is complex, I'm looking to make the most of a once in a lifetime kind of investment. To make better return on the investment, I can lower the payback time considerably by selling excess. I'm aware I'm well beyond the scope of a normal system install, I have "over engineered" things before and with time the pay back was worth it in one way or another. I ended up finding an MCS installer that is flexible enough to install things in the way I want so we will be fully compliant. Kit is nearly all installed already, regardless what the DNO approves I will either self consume/store or limit the export rate. yes I do have a smart meter, but I'm not sure which tariff I will use yet. I may end up using the flat 15p export and cheap overnight tariff. I'm also making progress with FIT that will pay probably 25% of my 8kw generation as well. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

it is G99 certified, I'm hoping to get 8kw allowance to export so that in theory should match my inverter and not need exporting control -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Thanks for the heads up guys. I now just need to figure out a way to get all the kit together and put the panels in place -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

do they require that as well for normal install or just for DIY? -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

the £250 admin fee is nothing close to the amount of money a MCS rip off company is trying to get to install the system. Solar PV installers in the UK are just taking the mickey with their pricing. I found a few topics, but they are reasonably old Has anybody managed to get a feed in tariff from Octopus without an MCS Cert? - Photovoltaics (PV) - BuildHub.org.uk -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

Octopus and some others are not requiring MCS for export. I can install it myself and still be compliant with their requirements to export as long it is all done properly. -

Help with first solar PV system shopping list using Victron kit

Alexx replied to Alexx's topic in Photovoltaics (PV)

20 to 30kwh a day no optimisers, I will have one MPPT per array, so no need for any optimisers I dislike the proprietary nature of microinverters. In my view, DC coupling batteries to solar PV makes more sense than convert DC to AC and then back to DC, then back to AC once load is generated. I even gave up on Sunsynk as it was my first option, but I want the system as open and modular as possible. I can just add a Victron EV charger later without needing any other 3rd party integrations for example. -

Hello! I’m in the process of planning my first solar PV system and would appreciate your help. I have 6 solar PV arrays, each with different orientations and angles. I’m determined to maximise the number of panels, including on north-facing sides, by covering a garage door with vertical panels and possibly flat-mounting a couple over a dormer. It might seem excessive, but someone told me it can’t be done, so I’m set on proving them wrong the hard way! Here’s my current list of major components—please let me know if I’m on the right track or missing anything: Victron MultiPlus-II 48/10000/140-100 230V (single phase) – For inverting and managing power. Victron SmartSolar MPPT RS 450/200-MC4 – For the 4 larger arrays. 2x Victron SmartSolar MPPT 150/35 – One for each of the smaller arrays. Victron Cerbo GX MK2 – For system monitoring and control. Victron Lynx Distributor – I’m unsure whether to go for the M8 version. As I understand it, this acts as a busbar to connect multiple batteries. I’m planning to start with two Gobel Power GP-SR1-PC200 16.5kWh batteries, with the option to expand to three or four later. They’re competitively priced, and I could profit from exporting at peak times or charging overnight. Victron Lynx Power In – Again, unsure about the M8 version. I’m still learning, but it seems to offer DC-side protection. Victron Energy Meter ET112 1 phase 100A max – For monitoring energy usage. For solar panels, I’m torn between: JA Solar 595W N-Type Bifacial Double Glass Half-Cell-MBB Aiko Stellar 1N+ 645W N-Type ABC – Aiko’s marketing claims they’re “shade-proof,” which I’m sceptical about. I’m aiming for 18 panels in total. For batteries: 2x Gobel Power GP-SR1-PC200 16.5kWh – These use EVE cells (same type/grade as those in EV battery modules) and offer great value. Now, onto consumables—I’m still working out the details: Cables: Between batteries and busbar—not sure if 50mm², 70mm², or 90mm² is best. Between inverter and busbar—same uncertainty. From solar PVs to MPPTs—thinking 6mm² due to long runs from the house to the MPPTs. MC4 connectors – For panel connections. Lugs – For cable terminations. DC isolators – One per MPPT, but should I have one per battery or just one for all? Better safe than sorry, so isolating everything might be wise. AC isolator – Between inverter and house. Does the inverter have a decent built-in one, or should I add an external one? Fuses – Should I include one per MPPT? Surge protection – Is this recommended? If so, one per MPPT? Bi-directional RCBO – For the AC side of the inverter. Mounting rails for the sloped roof, flat roof, and vertical setup are a challenge I’ll tackle later. Right now, I’m focused on getting the Victron setup sorted, as learning and specifying the right kit is taking up most of my time. Any advice would be greatly appreciated—cheers!

-

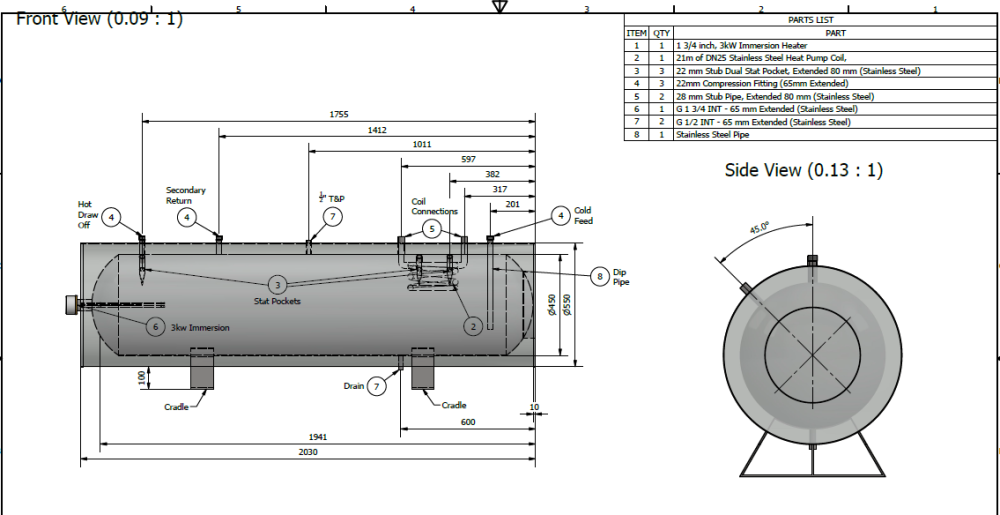

Nice, thanks for taking the time to help me with this, much appreciated. What do you use to do these drawings if you don't mind me asking? I've ventured myself into sketchup, but that was a bit of a rabbit hole for me. I've got word back from world heating, they cylinder is a bit longer, and the immersion heater on the dome, plus they can do a cradle that only raises the cylinder by 10mm for some extra pounds. So far, this seems to be the winner. I just need to check if 25 metres of DN25 coil is good enough. I could not get further details from other manufacturers yet on this aspect. Joule emailed me yesterday that they do not have any technical details on their horizontal cylinder, but it works and I can trust them. How come a company that makes the damn thing does not have a single technical detail to pass on?!?!

-

Yep, metric all the way. Last time the Germans sent stuff to the space station in metric when the Yankees were expecting in imperial, that did not work well 😣 Thanks for helping, very kind of you. Highest point that you can see at floorboard level against the steel beam is 970mm, horizontally from that point measuring 600mm further into the eaves, it becomes 710mm. It I raise the floorboards and get the cylinder and close to the edge to my staircase as possible, it seems to achieve similar clearance. I've asked world heat about their options, they can make a cylinder with a 10mm low profile cradle and the immersion heater on the dome side, which would allow easier maintenance. I'm just checking how big the de-stratratification kit is to confirm I can fit it all. Worst case scenario, I may need to replace the 8x2s with 6x2s. I'm already doing 200mm between centres to be at the far extreme of over engineering it just in case. If after installing the cylinder I have some room, I'll add another layer of 50mm PIR

-

I tried that as well, but when doing ceilings, and in my case worst, slope, I can't get the can upside down properly to get the foam out. Why do they sell these acetone/propane sprays as foam gun cleaners? is dichloromethane (I had to do a copy and paste) one of those substances that can be used to make crystal meth hence the reason they do not sell it on amazon?