john0wingnut

Members-

Posts

121 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

john0wingnut's Achievements

Regular Member (4/5)

12

Reputation

-

Timber Frame Wall build up for extension

john0wingnut replied to southcoastseagull's topic in New House & Self Build Design

Hey Ive now gone down the route of wood fibre insulation and sheathing boards as it’s all breathable. I used that ubakus tool mentioned above to get my u values sorted etc and it’s also useful to demonstrate phase shifting of heat through the walls and humidity control etc. John -

Timber Frame Soleplate overhanging cavity

john0wingnut replied to john0wingnut's topic in General Structural Issues

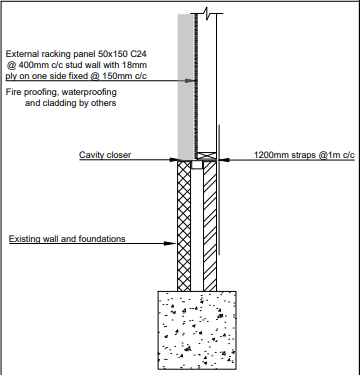

Hi all. It was actually the BCO who raised the issue with the overhang and asked me to discuss with the SE. I was also directed towards info from Trada / NHBC / LABC which advises of 20mm max overhang. The dwarf walls are 9 courses high, but do have a banked concrete infill which is just under the height of 1 internal block. SE came back with a new plan of using an IG9 lintel, but that just adds more complexity, so decided to go with a timber wide enough to span the cavity. I came across Steico joists in walls, which looked like a good option, which I am now exploring. Not exactly building merchant purchase, but there is a firm not too far from me that supplies them. Ive sent my frame plans to We Build Eco, who can then work those into a timber frame kit, which they cut in their factory then ship it up for building onsite. Also includes all sheathing, insulation, membranes, tapes and fixings etc. Will see what they come back to me with. I may well do it myself, or get a local chippy to build the frame, then I take it from there and finish it off. -

Timber Frame Soleplate overhanging cavity

john0wingnut replied to john0wingnut's topic in General Structural Issues

They were quoting me for it yes. Something like £250, so in the grand scheme of things for my rear extension / porch its a small cost for the extra belt and braces, so I may still do it. Just in contact with We Build Eco now to see whether they will quote me for a shell kit, which I can then build myself. -

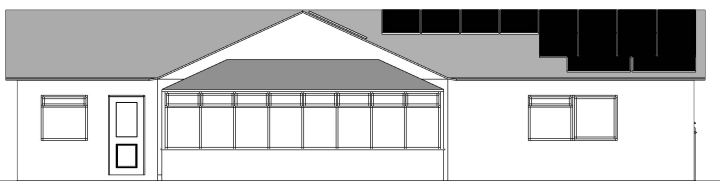

Well, I spoke too soon. Transpires that the original house, 1970s build, has an extra brick course on the left side vs the right. Im not even sure how that happens, given bricks are done in lines. So I have 2560mm from DPC to undercloak board on the left, and 2440mm on the right, which makes the above plan impossible now, as the fascia boards will never align. So I think my only option now is to lower the wall plate to 2350mm, then mount rafters on hangers on inside to allow enough space to fit a new tiled roof under the current one.

-

Timber Frame Soleplate overhanging cavity

john0wingnut replied to john0wingnut's topic in General Structural Issues

Exactly my plan When the conservatory was built they have put some wool batts in the cavity, however, its not been done very well. I pulled out one section and can see to the bottom, where the banked concrete infill is. My plan was to remove the lot, then fill the entire thing with polybeads. Majpell could be removed as you say. It wasnt in my plan originally, as, like you say, I was going to tape the OSB joints, but when I spoke with the insultation supplier, they advised adding it. John -

Timber Frame Soleplate overhanging cavity

john0wingnut replied to john0wingnut's topic in General Structural Issues

Pretty much what I’m now going to do. 240mm I joist frame. Cladding Battens Tyvek UV Facade 40mm Steico Duodry 240mm I joist with full fill steicoflex 36 18mm OSB Majpel 5 membrane 40mm service void with steicoflex 36 PB and skim -

Timber Frame Soleplate overhanging cavity

john0wingnut replied to john0wingnut's topic in General Structural Issues

The dwarf walls are already built and in place, as they were part of the conservatory, so there wont be a 140mm block, as its 100mm. The external face of the new TF will be vertical cladding, so masonry outer is staying as it is, with new TF dropped on top. -

Morning Looking for some advice from the forum. I am doing a conversion of my conservatory into a proper room, so a rear extension. Existing foundation and dwarf walls are being retained, and the plan is for a timber frame to be put on top. SE have put forward their plans which shows the 150mm TF sitting on the 100mm block and 50mm overhanging the cavity unsupported, see below. I queried this BCO when drawings were being reviewed by them, and they responded, advising they would expect the soleplate to be over both internal and external leaf's. I subsequently raised this with the SE, who asks to speak with BCO directly, only to be told BCO don't get involved with design aspects of the building, so wouldn't comment. I feel like piggy in the middle now, and not quite sure what to do, and whether what the SE has put forward is ok? As an aside, I had planned to put a row of Marmox blocks on top of the exiting wall, however, their guidance states max 20mm overhang and TF central over the block. Ive also read online that if one has the rafters notched to the outside of the wall plate, this could cause an eccentric load on wall, given the 33% unsupported. I also had a read through the LABC manual which sites 20mm max for 140mm studs............. Keen to hear the views / thoughts / advice from others on hear.

-

The width has in theory been reduced, as the 150mm timber frame will be sat on the inner block leaf (all be it there is a query re that being allowable due to blocks only being 100mm and thus a 50mm overhang into the cavity), where as windows are currently sat on the outer leaf. One thing I have now come across is a "Dutch Gable" where one essentially extends the existing roof at the base, then form a hip part way up. This I think will solve my problem

-

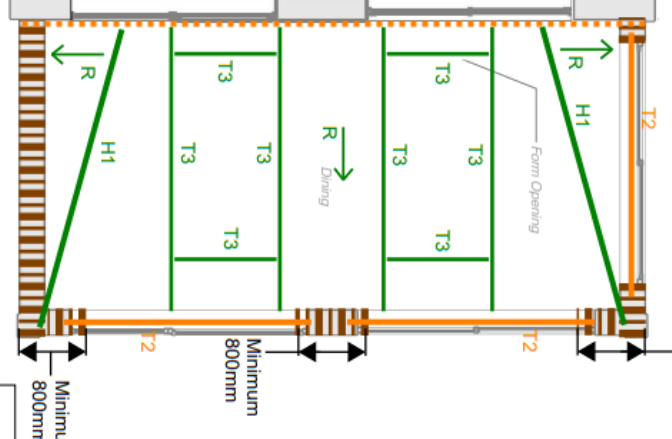

Evening, Looking for some help with a slight conundrum I have. Below is a view of the side of my house, showing the existing conservatory, with lean to, hipped roof. I am removing the polycarbonate roof and glass, retaining the dwarf walls and foundations. New timber frame walls and roof will then be going on. Below is the SE's roof design thus far. T3s surround the rooflites. H1 are hips. T2 are headers over the doors / windows. SE has specified roof timbers in 200 x 50, as span across the room is 3.4m. Jack rafters are max 1 meter span Now the issue at hand is the space between the new timberframe head plate, and the existing gable wall undercloak board is limited. The current conservatory window / door frames are 2100mm high, top frame is about 80 mm, then roof is about 60mm, so total height is 2240mm. There is then a 35mm gap and then 165mm barge board. Ive done a rough sketch below showing the new timber frame against the gable wall, with the top of the top plate siting at 2400mm. This leaves about 120mm to play with for rafters and roof covering, which doesnt currently work, given the SE wants 200mm rafters. Gable End Detail.pdf My only solution at present is to reduce the top plate height to 2350mm and change the rafters to 150mm. Im pretty sure the jack rafters could be 150mm, given minimal span, but haven't asked the SE yet. If anyone has got any other ideas / thoughts, I am all ears. John

-

Timber Frame Wall build up for extension

john0wingnut replied to southcoastseagull's topic in New House & Self Build Design

I’m currently going through the same process for my rear extension / new porch. My current plan is your thick option A, then tape the 25mm PIR layer to act as a VCL. 150mm studs, 120mm PIR inside and 30mm clear cavity. As above, I was advised to use rigid wood fibre insulation if I wanted to go the external route as it’s breathable. John -

I’ve just gone and looked up some of those posts by Brendon. Very interesting esp some of those live videos with data. Im tempted to get my system re plumbed with buffer removed now my system is fully de-zoned.

-

I’ve got the flows to a good point now. 2 rooms slightly higher than others, so will adjust down slightly, but others all at within .3 degs of each other. Im am also slowly adjusting the WC curve down, as most rooms still too warm.

-

Excellent. So I am on the right track. Currently on setting 3, it is very quiet. If I put it on 6 it makes an awful humming / whine sound

-

Hi all Im after a bit of a sense check on my UFH system pump setup / flow rate. System: ASHP is a 12kw Nibe F2040. SMO 20 controller 100L Buffer, plumbed as a 3 port. Wilo Yonos PARA pump with max 6m head supplying 2x manifolds. 175 sqm of UFH slab 17 loops, now fully de-zoned Heatloss from my calcs is 8.3kw at -3/20 dT5 Flow rate would thus be 1.41m3/hr or 23.6l/min I fully opened all the flow meters on all 17 loops, put the Wilo pump on max and then totalled all the flow rates up on each flow meter and got a total of 34l/min, which i then converted to 2.04m3/hr. Reading that max flow rate off of the Wilo Yonos Constant pressure pump graph at max setting gives a head of 3.5. https://www.ufht.co.uk/wp-content/uploads/2018/03/yonos-manual.pdf page 14 I then put the red dial on constant pressure no. 3 and got a total of 24.7l/min Is this then the correct setting for the UFH pump? Many thanks John