Mulberry View

Members-

Posts

758 -

Joined

-

Last visited

Everything posted by Mulberry View

-

My doors are being fitted soon. Can anyone share some tips/pics on EPDM Threshold detailing? My Architect shows the EPDM and main DPM under the insulation terminating under the door threshold, but I don't plan to have the DPM in when the doors go in. What can be done there? I'm looking at Illbruck ME220 and their formed corner pieces. This is an example of one of my openings... As usual, all help is appreciated...

-

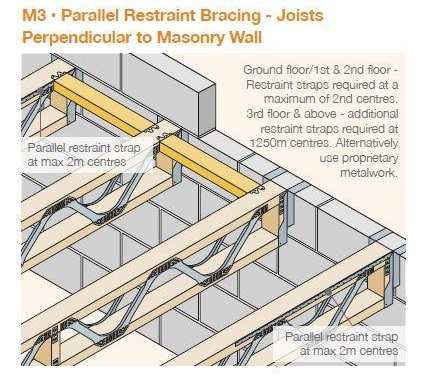

I top chord hung the Posis in the main house scheme, so I'm no stranger to the longer top chords, it's normal building practice I'm less clear on! So, I can sit the Posis directly on the masonry of the inner leaf blockwork and just oversail the top cord across the cavity to the inside face of the outer leaf? I'll try and sketch something soon.

-

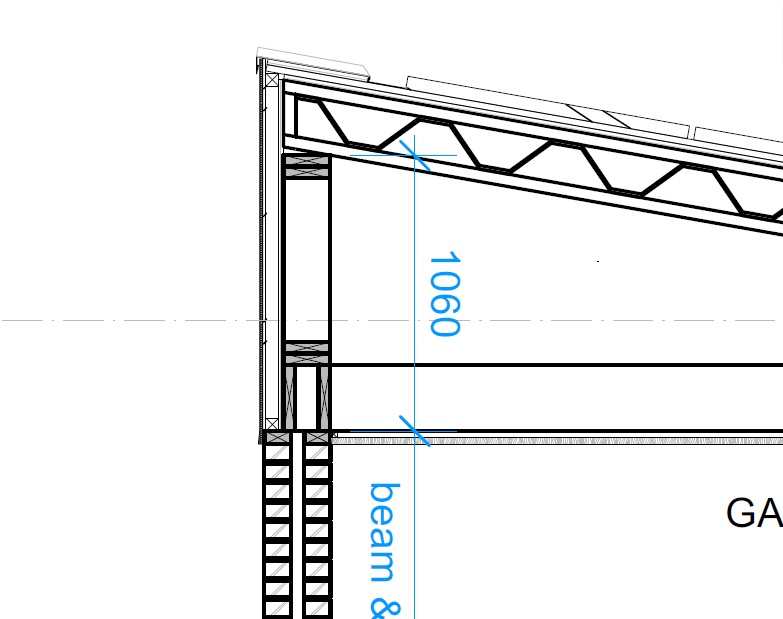

I just found this, could it be the way to terminate the Posi Joists at the high-end of the building? I need the masonry to terminate level with the tops of the Posi joists really because the outside will be rendered, with no traditional soffit. Obviously I won't have the extra course the detail denotes. Here the OSB would be fixed within about 130mm of the edge. The only question it leaves me with is how to deal with the OSB oversailing onto the flat-topped masonry? Or could I just foam the small resulting gap around the edge, then bring the inner leaf up around the Posis? I've asked Pasquill for their help, so I guess they might shed some light on it.

-

OK, so masonry terminated flat, wall-plate added also flat, then Posi essentially top-chord hung on the outer wall-plate (with some angled wedges) and fixed down. Where is the inner leaf brought up to? Built around the Posis or only to the underside if the Posis? Cavity closed? Sorry for all the questions.

-

Thanks @Russell griffiths To make the rest of the structure work, I can see me using a timber ledger plate bolted to the blockwork for the ceiling joists to pick up on. They need to resist pull-out, so I imagine I'll be using a combination of nails and screws, along with nailing the tops of the hangers over onto the top of the ledger. As for the wall-ties, I don't fully understand that, but will a brickie know what to do? Or is this just regular wall-ties as have been put in all the way up so far? I'm pretty sure the roof on this will be EPDM, so I expect I'll lay an OSB deck on top of the Posis, oversailing onto a timber wall-plate with angle-packers on the top of the masonry. Does that all sound right?

-

The £20k girl is history. That a blessing and a curse. I feel relieved to not have the arguments and arsehole'ish attitude, but we're left trying to figure out a lot of these weak details.

-

I am always grateful for the help on here, I couldn't have done this without. 😎

-

How would this apply if I go for blocks?

-

Honestly, I hadn't considered it being anything other than timber, blocks would be so much easier. Just goes to show what it's like having your brain scrambled when you're a bit out of your depth! What sort of blocks would be best for this? And yes, the drawing is shit, its what we got from a £20k Architect. Makes me feel sick.

-

This is a general arrangement detail for my Car Port, the layout is not something I'm looking to go forward with exactly. Can anyone help with a bit of practical advice as I'm not overly experienced in timber framing. The masonry is built, inner and outer leaves are level, as per the drawing. Next to go on are the 47x100 wall-plates (I've allowed 10-13mm bed). Does the masonry cavity need to be closed? If so, what with? Should I put a DPC under the wall-plates? I don't think I need 50mm battens for the render boards and by reducing them to 25mm, I can centralise the on-end 250mx50 timbers a bit better on the wallplates. I plan to add noggins between them. I also plan to set the outer wall-plate in a bit to allow the render boards to skirt down over the wall-plates, as we clearly can't apply the render in the way shown. Any help to prevent my further procrastination is gratefully received.

-

Front door level threshold detail

Mulberry View replied to Dave Anderson's topic in Doors & Door Frames

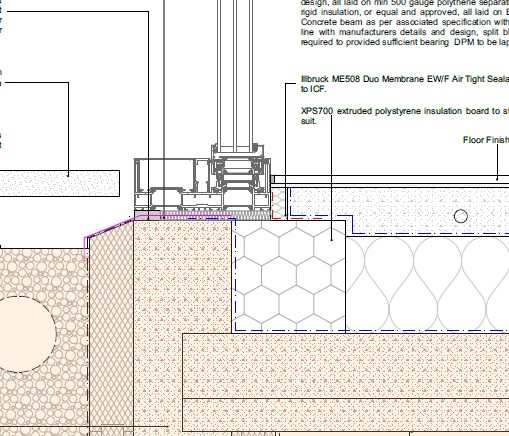

The main issue in the detail provided was the DPM... With it as per the drawing, I cannot fix the Compacfoam to anything up to and whilst the door is being fitted. It's also a fair old chunk, only because the SE said it needs to be as wide as it is tall to prevent 'mushrooming'. I guess the additional insulation needs to be protected from any potential damp coming up through the B&B? -

Front door level threshold detail

Mulberry View replied to Dave Anderson's topic in Doors & Door Frames

Thanks @Russell griffiths. Technically, I could strip the inner face of the ICF and lay a course of concrete bricks/blocks on top of the Beam/Block, directly up against the ICF concrete and top it off with a layer of something like XPS700 to aid thermal performance. But where would the DPM go? Presumably the blocks would be outside the DPM and the insulation would be inside it? Could I use EPDM as the DPC, fully bonded to the threshold, over the top of the added blockwork and then tape the DPM to it later on when I get to that point? In that way, I get to bond the XPS700 to the EPDM, which would hold it in place for the door to be fitted. -

Front door level threshold detail

Mulberry View replied to Dave Anderson's topic in Doors & Door Frames

Hi @Dave Anderson. Sorry to drag up an old post. Did you screed before the door went in? I need to add a piece of something like Compacfoam in a similar way to you to extend the load bearing width of the threshold to take a very wide profile sliding door. My dilemma is how to fix the Compacfoam in place, with some DPM behind it, whilst the door is fitted, as the PIR and screed won't be there at that time. -

Did find this which might be useful... Also Andrew the VAT man might also be a good one to ask.. Yes, services related to a borehole can be zero-rated for VAT if they are an integral part of the construction of a new qualifying dwelling in the UK. This depends on the following conditions: "In the course of construction": The work must be carried out during the construction of the new dwelling and not after it has been completed. A "qualifying building": The new build must be a self-contained house or flat designed as a dwelling. "Closely connected": The borehole and associated works must be "closely connected" to the construction, making the building functional and usable. This includes essential services like water supply.

-

Aesthetically pleasing Lintels?

Mulberry View replied to Mulberry View's topic in RSJs, Lintels & Steelwork

SWMBO suggested I make a form and pour these. I kinda laughed her out of the room. Is it feasible? I'd happily make a nice plywood form and pour it with a super-strong mix and rebar in it. These aren't carrying a lot in all honesty. Do-able?! I could deal with the cavity wall one having a "soffit cover", but the single skin ones are the challenge. Turns out the nice fair-faced concrete option will cost me £300, £200 of that is "haulage". -

Aesthetically pleasing Lintels?

Mulberry View replied to Mulberry View's topic in RSJs, Lintels & Steelwork

I've found a "fair-faced" concrete lintel option, I'm just waiting for a price. Hoping I can use those for the "internal" positions, I actually need 2 of those! For the "external" cavity position, perhaps I'll use a Catnic lintel and soldier course bricks?! I can't buy a fair-faced lintel in the width I'd need to bridge the whole lot. -

Aesthetically pleasing Lintels?

Mulberry View replied to Mulberry View's topic in RSJs, Lintels & Steelwork

Ah OK. Well, the Car Port is open-fronted and is linked to the house only with an open walkway (roofed). Thanks for your input. -

Aesthetically pleasing Lintels?

Mulberry View replied to Mulberry View's topic in RSJs, Lintels & Steelwork

The Car Port is indirectly attached to the house, but is aesthetically part of it. I'm thinking of using a conventional "Catnic" lintel for the cavity lintel and then seeking or having made a cover-plate for the soffit face of it. I may end up using a "Fair Faced" concrete lintel for the single skin and if I'm not totally happy with the appearance, I could paint it or cover it I guess. I just wanted to check there isn't a more obvious solution that I've missed! -

I need 2 lintels for walls that will be facing brick both sides. One is in single skin brickwork, the other has a 265mm cavity. They are open doorways in my Car Port, so they will not be rendered or plastered and won't be lined or have doors. Are fair-faced Concrete lintels the best bet here? I would use a more conventional cavity lintel for the 265mm position, but it'd need to have a nice smooth underside. Any suggestions?

-

Payment Terms - Pay everything upfront?

Mulberry View replied to Mulberry View's topic in General Self Build & DIY Discussion

Ah, so they let you pay with Credit Card OK then? I was planning to ask this tomorrow. -

Payment Terms - Pay everything upfront?

Mulberry View replied to Mulberry View's topic in General Self Build & DIY Discussion

I think that both Norrsken and RK Doors are quite reputable, but the gut-wrenching experience with our Zinc Roof has left us a bit scarred! -

Payment Terms - Pay everything upfront?

Mulberry View replied to Mulberry View's topic in General Self Build & DIY Discussion

Yes, we'll always push for that where possible. But what incentive do companies have to provide top service if they've already been paid in full?