gavztheouch

Members-

Posts

253 -

Joined

-

Last visited

-

Days Won

2

gavztheouch last won the day on May 24 2025

gavztheouch had the most liked content!

Personal Information

-

Location

Scotland Central

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

gavztheouch's Achievements

Regular Member (4/5)

67

Reputation

-

MVHR ducting to outside

gavztheouch replied to Moira Niedzwiecka's topic in Mechanical Ventilation with Heat Recovery (MVHR)

My house is 210m2. Anyone else have a similar m2 and if so what diameter of pipe did you use for the external piping. Zhender have a pipe that is pre insulated I think it is 160 internal and around 250mm external. im also going for wood cladding. It’s open rainscreen so I need to make sure I’m weather tight coming through the membrane. What did you use here, I’m thinking an epdm grommet if they come big enough or possible just tape but I think that is always harder than a grommet. -

MVHR ducting to outside

gavztheouch replied to Moira Niedzwiecka's topic in Mechanical Ventilation with Heat Recovery (MVHR)

Is it still recommend to put the inlet and outlet 2m apart? I see Zhender have a combined inlet/outlet that have the pipes right next to each other. I guess there will be a baffle arrangement to prevent cross contamination. https://www.fastlec.co.uk/zehnder-2x160mm-right-hand-external-wall-grille?utm_campaign=smartsh&gad_source=1&gad_campaignid=17190426677&gbraid=0AAAAAD8Nz9f-3-LzDnHIlsuV-MleAAoms&gclid=CjwKCAjw6vHHBhBwEiwAq4zvA_Lglcqpz9-48JocAj6NXNiC2dTtCF737MkcyS5OSb9FuJkesldSKRoCFYcQAvD_BwE -

Exposure time is usually rated for mid summer ie worst case you should be ok over winter. Make sure you have as many battens on as possible. I’m just putting my battens on now. Membrane has been on for 8 months already. It’s a black uv resistant version, even so I want it covered as soon as possible.

-

Moving in to an unfinished self build

gavztheouch replied to hbooth's topic in General Self Build & DIY Discussion

I’ve got 3 kids. 5,3 and 5 months old. We live in a flat we own about 1 mile from site. It’s about 70m2. The kids are driving us insane with the constant fighting and screaming. Our down stairs neighbour has had enough of our noise and this is stressing out my partner. There are no properties to rent nearby and my partner is desperate to get out of the flat. I phoned our self build insurance to ask if we were sleeping inside our self build would it invalidate the insurance and to my surprise he said no. It would cover the building but not the contents. so there is a possibility to move into a building site with three young children or some sort of hybrid living between the flat and build that will take the pressure of our neighbour. trouble is I’m missing 4 external doors and 4 windows. There is no cladding, and the inside is basically just stud work. I need some sort of plan to be out of this flat by christmas -

Retired chippy would be perfect

-

I’m looking for help finishing my house. Prob a good joiner or general builder would be best. I would love to work with someone say 3 days a week consistently. This would give someone guaranteed steady work, could be attractive vs bidding for work quoting etc.. Most big joiner companies don’t like just giving one man they usually come with a labourer which really pushes the price up and I don’t always have work for them. Any advise on seeking extra man power? Spoke to a local joiner could do two days a week but their rate was £50 which was a little steep I thought. Was budgeting on £35 I could sustain that for a few months at least.

-

How do you deal with the screw heads holding on the battens. I have screws every 400mm holding the battens on. Just wondering if they will be a problem when I come to screwing the cladding on. I haven’t done my battens yet so I could pre plan if nessesary.

- 63 replies

-

- cladding

- open joints

-

(and 1 more)

Tagged with:

-

Thanks Tosh, yes I’ve been in contact with metal solutions they are very helpful. The Glasgow depot is close to me. I liked the idea of cutting and folding my own cills. A future project of mine is to learn how to work the metal for standing seam roofs and cladding.

-

Timberframe cladding - Cost of cavity barriers and insect mesh

gavztheouch replied to AliG's topic in Timber Frame

I have an open rainscreen. Bought the rainscreen from russwood after conversation with my BCO he confirmed the open rain screen is not a cavity and therefore we don’t need fire battens. However my architect thinks they are wrong and are arguing with the bco for me to put them in! I know they know how much it will cost but I hope they know how much work this will take if I have to remove all the battens to get access to the wood fibre to cut a channel round the house to receive a hard batten to take the expanding strip. This will comprise the membrane too. Nightmare. If I don’t do it properly then the whole exercise will have been a box ticking exercise. But then why challenge the original decision in the first place. -

I have a metal roof made of green coat steel from sweden apparently it should last 50 years. Is this also a good material to make window sills from. I can get it up to 0.9mm I think.

-

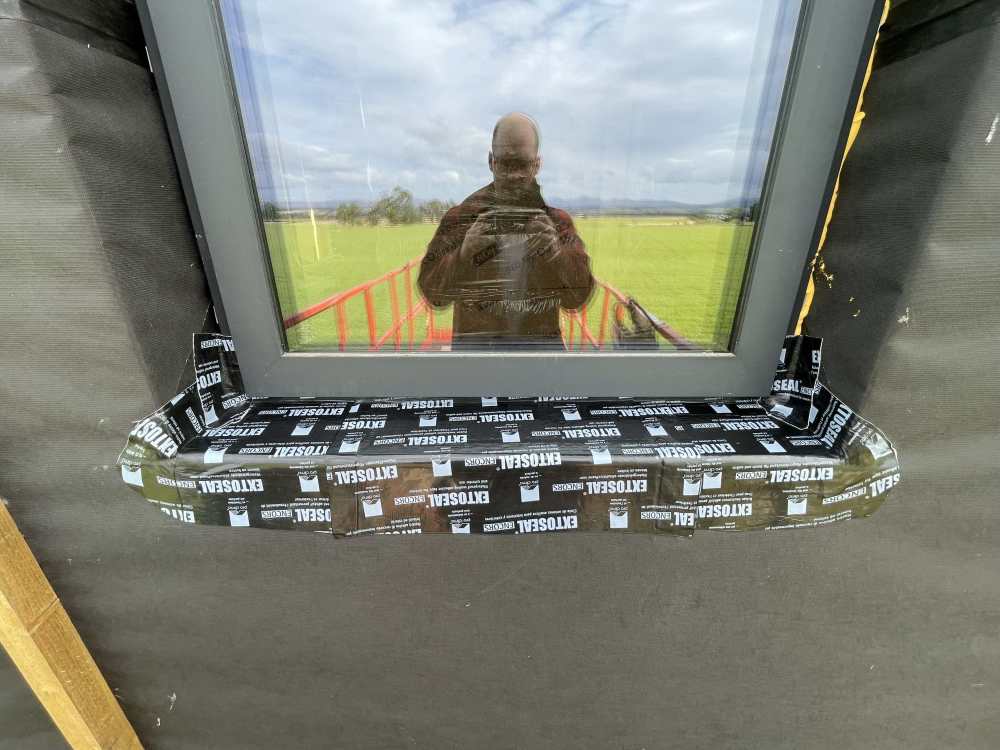

Started dressing in the windows on the outside ready for the cladding. I’m using extoseal for the sill and wood fibre insulation around the windows with a wrap of membrane around the insulation. Take ages per window

-

My architect detail has the membrane taped to my foundation which is an insulated raft. It is taped with a tape that can be rendered over so it covered with the concrete render that covers the raft insulation. I’m not sure of the idea of taping the membrane to the raft as any water that gets behind it will be stuck.

-

Cavity barrier and wood fibre insulation

gavztheouch replied to WisteriaMews's topic in Timber Frame

My building control officer has told me I can use an open rain screen and therefore have no cavity barriers. -

Hi I’m thinking about buying a roof rack to carry 4.8m timber on my van roof. It’s a standard van length (Peugeot expert) i think I need a full rack as the mounting points on my van are quite close together so a full rack will give extra support in the length. I think the rack is 2.6m long so I will have 2.2m of overhang to split between front and back somehow. The first job is to pickup some cladding battens which are 42mm by 42mm, they are 100 miles away and I will need to go on the motorway/dual carriage. Is it a bad idea to carry loads like 20 or 30 battons on a roof rack long distance. I have tried searching for pictures or folk discussing this online but I don’t seem to see anything. If they came off during transport it would be extremely dangerous