newbuild upnorth

Members-

Posts

27 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

newbuild upnorth's Achievements

Member (3/5)

2

Reputation

-

ive used BPC to design and supply recently, cheapest by a fair margin and very easy to deal with. ive also gone for the middle of the road system as I dont believe the pay back is worth the cost if im honest. I wouldn't have it if I could avoid it but thats my personal opinion and not really a popular opinion! I went for 2 units instead of one big unit, huge saving having 2 smaller units rather than the one big unit but this was also influenced by the kit design and running all back to one unit would have been a massive pain. the companies I engaged were split 50 / 50 on one unit or two so its nothing radical.

-

ive just been using sika 111 GP non shrinking grout to fill the gap around packers for steel columns, this would be the solution if you could mix it slightly dryer and pump it in with a mortar gun, might make a bit of a mess outside until you get the mix right but it is definitely made for the job. will it be over the dpc? grout wont be any good if its not as I reckon it might bridge damp over time but is definitely the right choice if its isolated with dpc between the blocks and the timber

-

good morning. Im working to Scottish building regs and finding it difficult to determine exactly what the building regs requirements are - actual documented standards, not just what building control may or may not want to see. approved document F is fairly clear for England, BRE398 is not much help, CIBSE guide B2 and I keep seeing passive house standard but that's not really what everyone works too either. does Scottish regs pin down exactly what they need anywhere or is it just as vague as it reads.

-

Soakaway fill material

newbuild upnorth replied to newbuild upnorth's topic in Rainwater, Guttering & SuDS

@saveasteading the salmon cages start off as big floating cages for rearing farmed salmon, when they reach the end of their useful life they get taken ashore and cut up. people use the mdpe pipe for all sorts around here as far as I know the companies give it away to save on paying to dispose of it as it would probably end up in a landfill. they fill them with concrete and use them for fencing, cut them in half and use them for animal feeding troughs, road crossing pipes, ducts, all sorts. the absolute best thing they are repurposed for is a community run company which uses the 90mm pipe for the frames of bombproof polytunnels, they have been designed and certified and you see them everywhere now, I even saw they were ordered for the Falkland Islands - proven to stand up to over 100mph wind in shetland. they are called polycrub and have a Facebook / website, worth a look as it is brilliant. im going to look into using the pipe as some sort of fill or attenuation a bit more, I think you are right about being better used in length with a lot of holes in it. -

Soakaway fill material

newbuild upnorth replied to newbuild upnorth's topic in Rainwater, Guttering & SuDS

this is something that may open up a whole line of questioning, I see that all the baskets for sale have a rating of 20 ton or 40 ton so this may be impossible to prove. -

Soakaway fill material

newbuild upnorth replied to newbuild upnorth's topic in Rainwater, Guttering & SuDS

its just an idea, ive not decided on it, I dont think sepa has anything to do with suds though, certainly not for my building warrant, calculated by calculators and stamped by building control, its only for the rainwater not for sewage. and its very vague, perhaps because of where it is and how readily the ground takes the water, it isn't like its designed, just example Soakaways and required volumes. -

this is just a thought I had so anybodies experience or thoughts are welcome. im not far away from digging my Soakaway - for rainwater - all the calculations have been done and I need 3600 litres of storage capacity in the Soakaway for roof runoff, the details give a typical Soakaway detail using crushed rock as the fill with only a 40% void ratio, it then occurred to me to explore crates - 95% + void ratio. for our own scenario, space isn't an issue, and the ground is pretty forgiving so we can have long / shallow / deep / wide / trenches it doesnt matter really. if im doing the work myself there won't be much difference in cost, crates will be dearer but smaller hole, rock will be slightly cheaper but bigger hole and more work. I can't see anything that is a hard and fast rule for what you can and can't use, everything refers to BRE365 which again isn't particularly specific, the rest of the internet by and large has it one or the other, rocks or crates. what if we could easily / cheaply get another material for fill, up here there is a huge quantity of used MDPE pipe from salmon cages, people use it for various things but it doesnt really have any value so it is often seen as an opportunity to recycle. im thinking that if short sections of this were used as fill it would easily be up in the 90% void range, its as tough as can be and MDPE is what they use for civils so its proven not to degrade or leech. common sizes are 90mm OD so it this was roughly cut into 100mm / 150mm / sections and just thrown in randomly as you would with rock I dont see how this wouldn't work, plenty void for storage and easy for the water to makes it way around and through. I wouldn't try it under a driveway but down the side of a field I dont see how it would be much different in settlement or compressive strength than crates. any thoughts or experience in not using crates or rocks? or why the MDPE pipe as fill wouldn't work?

-

Have thermal stores had their day?

newbuild upnorth replied to Workerbee's topic in Boilers & Hot Water Tanks

@JohnMo this is exactly what id like to do but im struggling to find a training venue that dont want xyz qualifications, and none are so far interested in experience as a selfbuilder, any chance you could share which college you did the training at? -

our BC want a witnessed air test on all soil pipes before they get buried, I think it was 100mm/hg for 10 mins so I had to plug and test 3 individual branches to the chamber with them there, and then a final test before completion certificate which includes all traps at I think 50mm/hg

-

what's a proper alternative though, in the instance of EPDM or GRP, im not convinced straight onto PIR is a good move. I would rather have EPDM or GRP on OSB or ply personally. assuming the VCL is a good one and fitted properly, assuming the PIR is foil faced and taped, and assuming the fixings holding it all together are thermally broken where is the moisture coming from to cause the interstitial condensation that is going to rot the top layer of treated wood?

-

ASHP flex hoses

newbuild upnorth replied to newbuild upnorth's topic in Air Source Heat Pumps (ASHP)

Because i wouldnt get pipes up my ducts @JohnMo i havnt thought about how ill seal it but id imagine a bit of armaflex and sealant will hold a few psi. -

ASHP flex hoses

newbuild upnorth replied to newbuild upnorth's topic in Air Source Heat Pumps (ASHP)

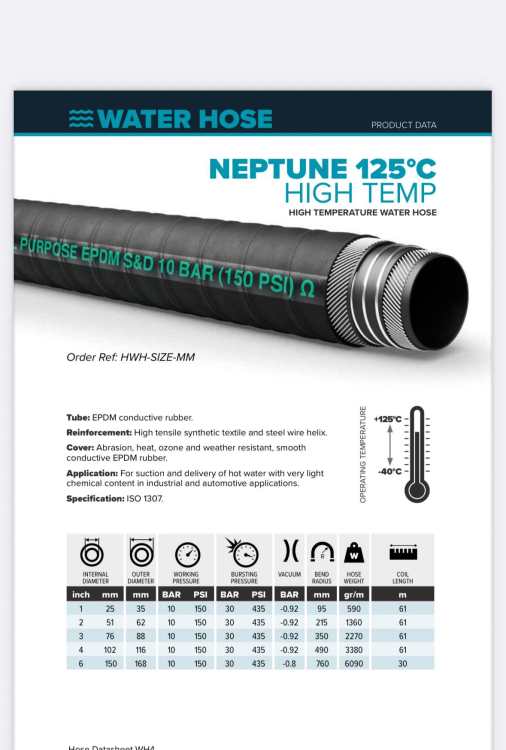

Thanks for that @Nick Laslett thats just the info ive been searching for. looks very similar in spec to this stuff which i could get by the meter and get hose tails for, ill search some more to make sure theres no max guideline for hoses but i cant see why there would be. Im not planning on going crazy just 1.5 - 1.8 meters maybe. -

ASHP flex hoses

newbuild upnorth replied to newbuild upnorth's topic in Air Source Heat Pumps (ASHP)

Well if i can get long ones i wont need multiples. I need flexis off the unit then also flexis up my ducts. if i can be confident in the spec i dont see any reason not to run hose from the unit to inside the house, potentially less heat loss, less joins, less turbulence? I dont see any negatives. -

Does anyone know the specifications of the flexible hoses used on ASHP. is it just 10 bar epdm lined hot water hose with a stainless braid? Basically im looking for longer hoses so i dont have to go from flexi to pipe to flexi to pipe and in doing so reduce fittings and connections.