SelfBuildSmurf

Members-

Posts

18 -

Joined

-

Last visited

Personal Information

-

About Me

Taking on the renovation of a 1970 house while adding a two storey side, single rear and porch addition at the front.

-

Location

Cambridgeshire

Recent Profile Visitors

620 profile views

SelfBuildSmurf's Achievements

Member (3/5)

5

Reputation

-

I was under pressure to get PIR down, UFH installed and pressurised to get the CemFloor installed pre Xmas so I got a fella in to do it in the end. He flew through it and did a great job tweaking a few bits on site that the layout plans hadn't allowed for. It was sad, yet a relief to see it disappear under the screed! And another +1 for liquidscreedpumping.com if in the East Anglia area 👍🏼

-

Thanks both, I'll have a look on Marketplace etc, failing that I'll go for the sore thumb option!

-

Afternoon all, Could someone advise if the loan scheme is running, or does someone have a decoiler and staple gun for sale? The lovely people at Underfloor Parts have dispatched the materials required for our UFH design so I have a few busy nights ahead! Thanks

-

3 Counties Concrete (Herts, Cambs, Beds) We're exceptionally helpful, and we got 6 m3 in, tamped in just under two hours 👍🏼

-

Morning @Nickfromwales, This is the structural ground floor slab, I excavated the existing slab to allow for the new floor build up. Once the slab is down, then it's a layer of PIR across the new slab, existing slab and the B&B floor. Then UFH clipped and screed over the top. As the new slab will be abutting What's left of the walls I've demolished I wasn't sure whether to use the UFH foam to, in a way, decouple the new slab from the existing structures to allow for expansion & contraction. Thanks

-

Afternoon all, I'm having concrete pumped for our new slab tomorrow morning and just had a thought...... Where the new concrete slab butts up against existing structures, i.e. old foundation, external and internal house walls etc. would would it be wise to put in some UFH edge strip to allow the slab to expand/contract? Or just poor it tight to the existing? On top of the slab will be PIR, UFH and then finished screed. Thanks

-

DHW/CW Manifold location & configuration

SelfBuildSmurf replied to SelfBuildSmurf's topic in General Plumbing

Thanks @crispy_wafer, I was looking at the plastic duct chambers and perhaps doing the joints in those, while it means they are accessible they would then have to be a decent size to allow bending the mdpe back out of a connection and in again if they ever needed to be changed, And if they're unlikely to ever need changing, then why bother with the access chamber, Another example of the procrastinating I'm doing! -

DHW/CW Manifold location & configuration

SelfBuildSmurf replied to SelfBuildSmurf's topic in General Plumbing

Also, if I may. I'll be running a new 32mm MDPE main along the same trench and I see Plasson couplings are well thought of on the forum. I will be using at least two tee's to split the new mains feed, one x 'front garden tap', 1 x 'house supply' and 1 x 90 for a 'Rear garden tap'. Would you try to keep the fittings accessible or are they genuinely a fit and forget product? Is there a preference between push-fit / compression? If accessible any recommendations on how? Thanks -

DHW/CW Manifold location & configuration

SelfBuildSmurf replied to SelfBuildSmurf's topic in General Plumbing

Thanks again for the insight @JohnMo, I understand what you mean @SimonD, as a compromise I've seen some run from central manifold in 15mm to a manifold in the bathroom and then split to outlets. With en-suites typically used morning/evening in conjunction with a shower I guess it reduces the time waiting for HW to arrive. I can see from the forum that Hep2o manifolds are well recommended I've seen repeated reminders by @Nickfromwales and others to ensure any garden taps are not connected to the DW manifolds. So I'll start sourcing those material in due course, I'm now back to weighing up whether I do have to sacrifice part of the utility room for ASHP performance and efficiency (i.e. locate the UVC in there and associated plumbing/manifolds) or whether the ASHP could still perform efficiently if I extended the flow and return to the plant room. But looking at the specification tables it appears just the now installed subterranean flow and return (22m pre-insulated pipes with ID of 42mm) may be a little over ambitious....... I'm now thinking a run similar to that outlined below (approx 30m ish) would definitely be a little too ambitious! As a side note, it's today that I really wish I had concentrated and finished my M&E apprenticeship all those years ago. -

DHW/CW Manifold location & configuration

SelfBuildSmurf replied to SelfBuildSmurf's topic in General Plumbing

Thanks @JohnMo, Are your manifolds serving multiple showers as well? Do you notice any drop in water pressure etc. or noise issues if two showers are in use? -

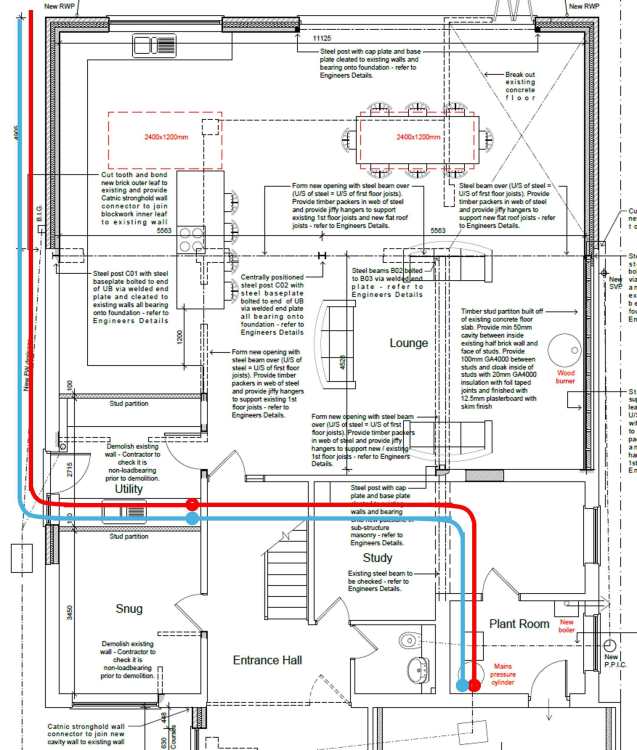

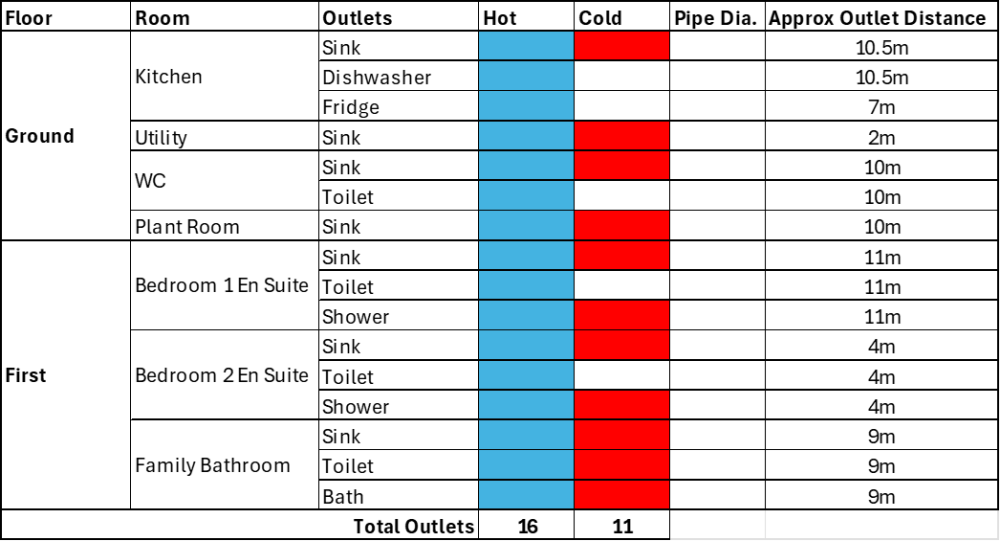

Evening all, I'm trying to finalise a plan for re-plumbing our renovation but excessive procrastination on my part has me here seeking guidance from BuildHub members, In short, we are renovating the entire house which necessitates a re-plumb and re-wire, We are moving from gas fired Warm Air Heating (Brink B-23D) and Immersion hot water to an ASHP with Unvented Cylinder (finally hot water at decent pressure!). We have a HeatGeek proposal from a local installer, but I have decided to take on the UFH downstairs and UFH overlay upstairs to reduce the quote, and owing to build timescales I have run a length of pre-insulated pipe below ground from the proposed heat pump location to the utility room shown on the drawings (approx 20m). House heat loss has been calculated at 13.42 kW and the design done to -3.0 C (Cambs) - Vaillant aroTHERM plus 12Kw Heat Pump - Vaillant uniSTOR 300L HWC We would like to install a Water Softener too, as we are in a hard water area. I had initially intended to put the UVC and plumbing manifolds in the plant room but it would result in a pipe run from plant room to the kitchen sink of approx. 22m which strikes me as being less than ideal. As the insulated pipe for the ASHP comes up in the utility room, I am now considering putting the UVC in there as well as the plumbing manifolds, I am yet to run a new 32mm mdpe mains supply, which will be either into the utility or plant room once I've bitten the bullet! I've come up with the following manifold configuration for outlets, Redacted Drawings.pdf Being more familiar with a branch and tee system, could I ask your opinion please on the proposed manifold configurations for DHW and CW please? - Given the length of the runs would you instead opt for one run to each room and split within i.e. a 22mm run to a manifold in the bathroom and then 15mm feed to each outlet? - Is there a general rule of thumb on pipe size to certain outlets? (i.e. 22mm to bath, 15mm to sink etc....) - Any other general pointers? I've attached the floor plan below

-

Hi @mk1_man, I would like to know more about your experience with air2heat please? I've had some obscene quotes for an ASHP, and given the entire house is being renovated room by room and the house needs to be replumbed, and have UFH installed I think id prefer the DIY at my pace route. Are you a plumber by trade? Thanks

-

That's odd given all the European directives around transparency and consumer rights that they would withold such data. I'm liaising with Welthaus now, extremely competitively priced and a decent offering of doors with details I can review and implement on the build. Totally feel your pain about aspects like this feeling far more difficult than they need to be! I may just use some of this new pricing I've obtained to leverage against local suppliers/fitters!