jamesdiyer

Members-

Posts

83 -

Joined

-

Last visited

Everything posted by jamesdiyer

-

Grant/ Aerona ASHP expensive...

jamesdiyer replied to JeffGiraf's topic in Air Source Heat Pumps (ASHP)

I live in a big stone house in equally cold environment. We are doing around 2kw electric input currently at 2C. However we are warm at 20C inside. Contrary to what some people think, it can work very well with the right emittors. If you're flow temps are high but you're not warm, I'd say you have an emitter issue - emitters too small. You need to get a grip on the UFH and why it's not working well - I'd say the landlord should be paying for someone to look at it. It sounds like the whole thing is a mess and needs to be dealt with properly. -

So there hasn't been an update on this as I was hoping the installer would have some decency, sadly they're now a ghost. With it being winter I can't do much. However due to issues with antifreeze being too high and two connections leaking I needed to resolve the situation behind the machine. I took the opportunity to swap the hot mess of 90s to a braided flexi. And as prediction the flow rate went from 1740 to 1860. It's not pretty as the plastic pipe is a bit long but I don't want to drain the whole system to fix it, I'll sort it in the next warm period or properly in summer.

-

We have a 15kW Aerotherm plus. It's the same hardware as the 10kw as far as I can tell - min modulations are the same etc. They also do a three phase version of this.

-

I think for something like that cascade of two machines could be nice. Low modulation for mild temps and can maintain internal temp and a second machine for when really cold. It's going to be really important to get the right design and install done. Different machines modulate to different levels and others cycle better than others. I've an oversized vaillant and it works good. I should have had a cascade setup on reflection though, as the only time we are cold (and not actually cold but not perfect) is during mild temps. The specification pdf on that Panasonic doesn't seem to give a minimum heat output figure at X degrees C, which is what you really want to know to decide between sizes. Without being crass, you're clearly not poor. If I were in your shoes I'd find a really hot installer who knows their stuff and pay them the money to deal with the problem and guarantee it - I'm sure you've better things to do with your time than deliberate this.

-

Noise reduction at 60% doesn't help. So clearly the compression isn't ramping on at that higher rate (power input in still the same as it was without noise reduction around 1600W). I guess this means it's doing a good job of not starting too hard, but I feel it could do better if it started lower % of compressor speed max or modulate down faster.

-

Yes, I feel it's running in that way, and because we have a 15kW beast, at mild temps circa 10C it heats it really quick. But for example, it's 10C out side right now. But with a huge north wind blowing and snowing 500m above the house. So when it cycles off you can note that it's off. Perhaps increasing radiator surface area would help dissipate more heat and decide the increase of return temp. Also I don't think it's a situation of needed to increase weather curve (unless maybe it is) as when it's running and maintaining the flow temp of the curve 0.7, it's maintaining temperature in the house. It's just because it can't modulate low enough and then cycles off. I did wonder about pushing the curve a bit higher so it can keep running, but I think we would then be hot.

-

Thanks for the quick reply and thoughts. Yes I was reading around this but wasn't sure how helpful it would be in this case. I was trying to set up decent monitoring to be able to have data but struggling with that. I don't think it's coming on that strong (I haven't bothered to stand by the box and watch it, but having seen on the app we are hitting ~1500W power input, at lowest compressor speed I see around 950W depending on outside temp. Our unit is quite oversized, while we complete renovations, so we cycle down to 4C. Though we will see -7C overnight quite regularly, and heating off as 15C due to solar gain - so our cycle range of temps is shifted lower. I do think it's cycling well, but if I could get it to pace it's on a bit, I think it might run nicer. I can note the off periods when the temp outside is circa 10C and you can feel the lack of heating I to the house. I guess I could put it in noise reduction mode during the day time and see if it helps. But really I need graphical data first. I would leave it off overnight as we need it to be able to run full to meet potential heat loss at low temps.

-

Regarding the cycling of the vaillant aerotherm plus, has anyone looked into or got information on the power it starts a cycle with? My machine seems to cycle well, however I feel it comes on at a higher rate than needed which pushes temperature up fast, where as if it started at a low compressor speed it wouldn't rap so fast and on cycle would be longer. Maybe it needs the compressor speed to get going and is just how it is.

-

Yes! Exactly.

-

Would you propose using a Flexi to exit the back then? As we need to make a 90deg to enter the building. Perhaps just bend 35mm plastic

-

Interesting. I guess the UFH has it's own pump, and perhaps your rads are lower pressure drop.

-

Maybe I'm way off base with these things and I'm happy to be told I'm wrong. Just trying to find a way forward to best alterations to have a 'ideal' base install.

-

Yes okay thanks for your time explaining that. Looking at a DN32 ESBE 3way, the KVs is 16, so (18.5cV) so the pressure drop would be ~ half or 3.5kpa. I'm not sure that's insignificant. If I'm saying moving from 26mm i.d. to 32mm i.d. primary will reduce pressure from 12 to 4.5 kPa, a reduction of 7kPa.

-

Yes you're right I am. I have seen others mention using bigger 3ways for bigger pipe. I just wondered if it's better the change what's possible, while there changing pipe, than then try come back later and do it. I'm going around on all aspects to decide what I request is changed and what can stay. Because if we change some stuff and can't hit near 2000 then I'm going to annoy the installer - who just wanted to put a buffer in in the first place (but fitted as volumizer on request), so I'd rather get it right second time and hit as needed.

-

also what 3 way diverter are you running? Maybe this should be changed on mine to, while we are making changes.

-

What's the length on you primaries? Mine are 22m total. For sure I also have some loss due to the smaller valves that need changing and the rogue 3m of 20mm id pipe. Plus those plastic fittings are even smaller diameter so add greater restriction.

-

Thanks that makes sense and yes it's set to 900mbar. I can't see where to find the notice on if it's met. The manual says live monitor can show stays codes but I can't see them or a menu inside to access.

-

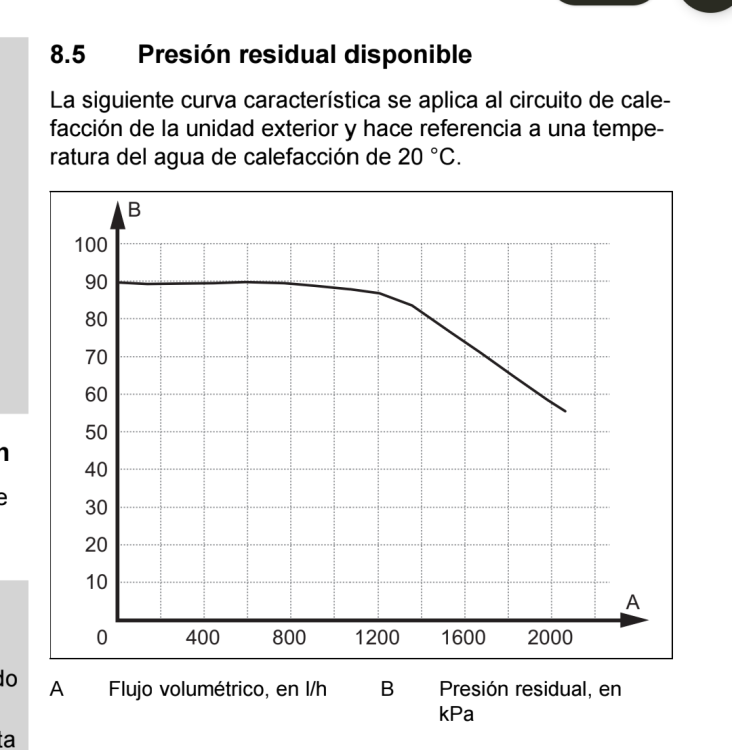

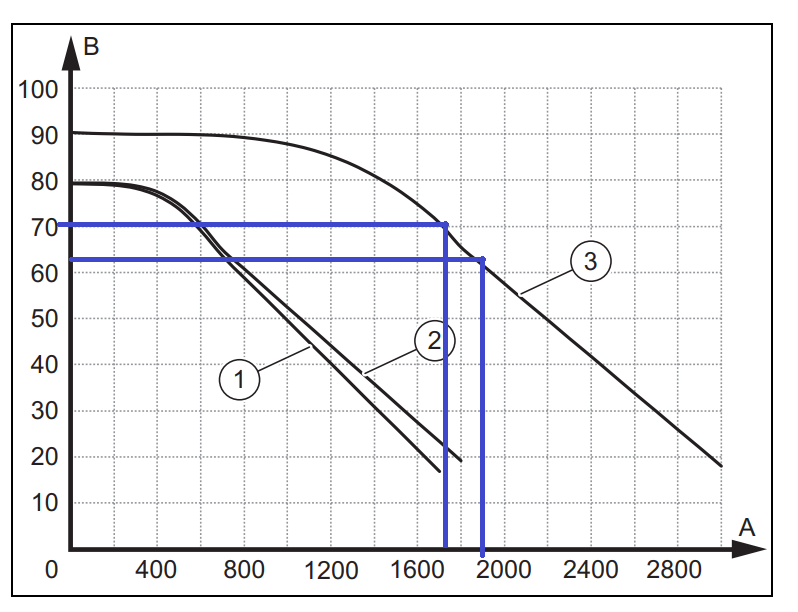

Thanks for the explanation. That's interesting. The graph, which I didn't copy well I re attach. It is 'residual.pressure available'. Page 39 here https://www.vaillant.es/product-images/0020326641-03.pdf.pdf Let me have a think about your point, though I think it would be a case of pushing vaillant to confirm that, after having changed piping. I'm just concerned about pushing the installer to change piping, but not for a buffer, and then still not hitting this magic flow rate. And then having the fit a buffer still, or just not fitting a buffer if we hit a flow rate I deem ok.

-

Thanks for the explanation. And yes it seems a buffer was initially specified here, because it just makes up for other inadequacies in planned inital install.

-

Hi, maybe I've made a false assumption, but I read it from the pump graph from vaillant posted above. Flow rate l/h v Residual pressure kPa. Dies it not work like this? If we have flow of X at pump running 100% then it's working against pressure Y?

-

Can somone point me to a post on how a true buffer tank would work. I'm assuming it just does it exactly the same way as it would without a buffer (running true WC) and then that heated water in the buffer is pushed around the circuit by a secondary pump and then is returned colder which retunes to heatpump. The inefficiency people talk about comes from lost heated water that's mixed in the buffer and secondary pumps. I'm still not sure we would hit the magical 2000l/h from just changing the primaries - it would be close and depend on what losses are incurred by the connections and 90s. At 1750l/h we have a pressure of 70kPa. I calculated the current primary as 11.5kPa and that reduces to 4.5kPa for 32mm internal. Being generous we come to 60kPa which moves is to 1900l/h. This does give a 11kW at delta 5C or 13 at 6. The 15kw machine is capable of 11.3kw at -7C for 45C - so having more flow doesn't seem needed, but perhaps I'm overlooking something. I'm inclined to think a simpler system the better. But maybe I'm making a mole hill and just re plumbing the volumizer we have as a buffer is just ok too. Shame this subject seems to be a bit of a (unnecessary) art and argument on what's best with different experts.

-

Yes agreed. So best to get it sorted now. Installer called me right up after sending the report and was happy to engage and work to remedy issue in manner I'm happy with. So we will get there in sure.

-

It's worth noting I've a cop of 4.2 over the past two weeks (heating only). And the house is warm, we haven't been to -7 for a week but have been to -2 overnight. This is also with cycling, given it's mid autumn weather. The HP runs maybe half the day. (I think cop isn't far off accurate as the flow and return temps with heating off but pump on read the same temperature). I think our heat demand is 9kW (with .5 ACH number). I don't think with the current flow we will have an issue being warm now - but we might when I finish renovating and need to heat another 100m2. Right now I'm actually quite satisfied with how it's working. A couple bedrooms are a bit colder, but their radiators are undersized, which actually is advantagous as downstairs can thus be 21 and upstairs naturally finds itself around 19 in most bedrooms, for the curve flow temp.

-

Yes 32mm internal. And again, it's a situation of computer says. He doesn't run a heatpump at home so it's only from what the computer (vaillant training) has told. The installer has said he's happy to change the pipe, though there will be a small cost to me - which seems fair. The issue with 40mm plastic is it's 4m long bars which will need connectors that reduce flow. The alternative is 35mm copper which has full bore connectors. And hope this change is enough to bring the flow rate up and avoid fitting a buffer. My calculations make me feel it will be.

-

This is what the vaillant report said: >Direct aerothermal installation with 2 radiator circuits and a 200-liter return tank. The minimum flow rate for heating, with the pump at 50%, is 9641 l/h, and at maximum, 17171 l/h, and for domestic hot water, 1615 l/h. These are low flow rates because the piping is 32 mm multilayer and everything is supplied by the unit's own pump. It is recommended that you use 1.25 inch piping, the return volumetric tank as a buffer tank with a sludge separator on the return line, and separate pumping units for each circuit because you may have flow rate problems that would not be covered by the appliance's warranty. You have purchased components from Germany, and a different part number is listed. You will speak with the installer to modify the installation and improve flow rates.