testom

Members-

Posts

17 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

testom's Achievements

Member (3/5)

8

Reputation

-

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Hi, Pleas see attached service manual. Regards T puhzw90vha.pdf -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Thats correct. By the way of update-I have manage to replace (so far) 11 radiators to a new type alloy made. Still 4more left to go. I will do it after x-mas. One single alloy radiator takes (approx) 3 liters of water. In compare to steel radiators - thats 50 liters of water less to heat up in my system. -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Straight to 24V DC power supply. Regards -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

By the way of update. All my current panel steel radiators will get replaced to aluminium radiators. Delivery expected next week. Can`t wait to replace it all. And the price was 1/3 to what I was asked to pay for special low temp radiators. -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

@PeterW I have found that B2 & B3 terminal gives +24V as a output signal. I have finnaly plugged two small LED`s there. And I must say this LED`s gives nice indication to what is actually going on with ASHP. -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Please check my previous posts. I`ve uploaded few pics there, where you can see entire ASHP separate loop (filled with glycol). Capacity of this loop is approx 5.5l. And yes-I am using separate pumps. One circ. pump inside ASHP loop (pictured), and two other pumps on internal CH instalation- DHW and CH separate. You can use 3way motorised valve from h.exchanger to split to UFH and DHW. Just remember- for DHW you will need separate "simple logic control unit" (thermostat etc.etc.) as you need to run ASHP at approx 60 degree of C. I do not have a 3 way valve fitted at my installation. Instead I installed so called "flap valve". Simple valve - no extra cables needed, last forever. -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Hello @PTUK I will put few words from me. This ASHP needs approx 25l/min of liquid flow to run without errors. Make sure you can provide that kind of flow. Otherwise you will get errors. To run this ASHP on 42% or 33% (you dont need more output power for 45m2) you need to keep only one active input- A3 for 33% or A2 for 42%. To choose between power modes simply you can use two way switch. You can even put 2 gang 2 way switch from Wickes for £1.50 and you will be able to choose between 33%,42% % 53% of its power. Keep it simple. I also suggest to separate ASHP liquid loop from the house internal istalation (just like I did) with plate heat exchanger. No further worries in terms on outside temp. dropping below zero and unstable liquid flow at the ASHP. Happy to provide some more info/drawings if needed. And at last- yes 5bar is the correct figure for pressure test. -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Highest temp I get at 77% is 62C. Never tried on full power. But I will play with it in the day or two. Interesting. BTW @JSHarris - I did quoted online low temp radiators from local supplyer. Replacing all 14 radiators will cost me ... 3300Euros. Question is- will this be wort it of doing? -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

18kW is the "size" of my oil boiler. And yes 9kW heat pump will newer deliver enough heat to cover fully my requirements, but I need 18kW of heat at -18C. So for now relax - only -3C during the night. I also tried to convinced my other half to demolish entire floor to get underfloor heating, but how to say - the answer was ....NO!!! , so yes indeed good idea, time to think how to get low temp radiators, cos this would be a "low invasive project", so my moaning wife will keep her mouth shut . -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Your calculation is correct. It is what it is. According to my energy certificate my house requirement on heat is 100W/m2 when -18C outside. As a reminder- my house has 186m2 of living space. Also I have plugged this heat pump to standard central heating installation based on radiators. For last 3 weeks average outdoor temp + 2C durring the day, and -3C durring the night. Pump still set to (1) MAX 77% of power, and for most of the time (when is runing) it is sitting on 53% of power. I did try to increase it output power to 88% - and yes, average running time went down, but energy consumption was higher than normal. I dont mine if it runs for such long time. If I would have underfloor heating I can imagine that concrete floor would work as a buffer, and ASHP would run differently and at lower temp set. @JSHarris not sure how you doing this that your pump runs approx 1h/day. Respect. You must been living in so called passive house, and your energy needs are super duper low, or you have set internal termostat to 15C . I have to admit - I have never used so little(cost) energy in the past(heating oil) to keep my house warm for 1 month period. Last 24 days electricity consupion by ASHP will cost me aprox 85Euro. In the past for same period I used approx 200l of heating oil (160Euro). By the way - I have set to my self a 5000kWh limit of electrical energy I can use durring this seson. I will be in touch with you gents from time to time and I will keeps you updated on usage. -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

I can fully confirm to @PeterW message. Also I wish to write few words in terms of Defrosting. I had a chance to witness such moment when pump switch itself to defrosting mode. Entire procedure took about 90sec. Durring this process compressor speed went down a bit. Temp at the hot outlet from the unit dropped during this process from 50C to 13C. After this short moment unit returned to normal mode. By the way of update: for last 24 days my ASHP consumed 685kWh. Total working time 336h. Average load 2.04kW -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

I have checked the distance from the wall 34cm at my place -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

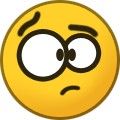

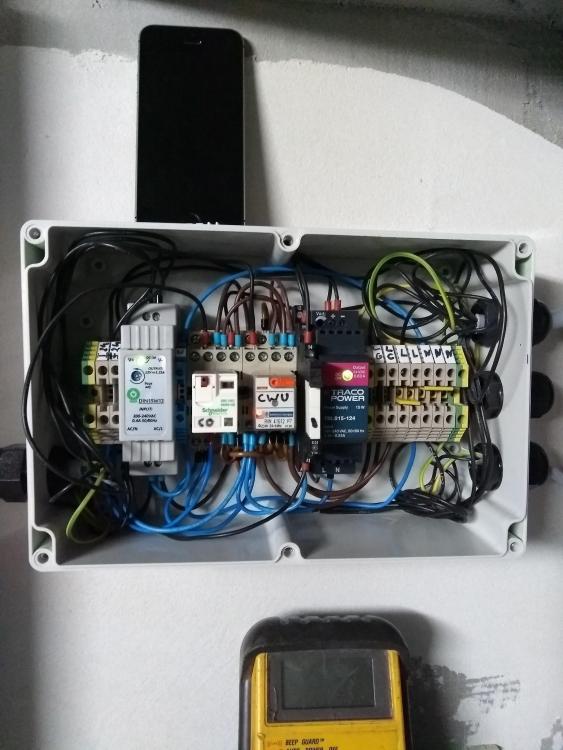

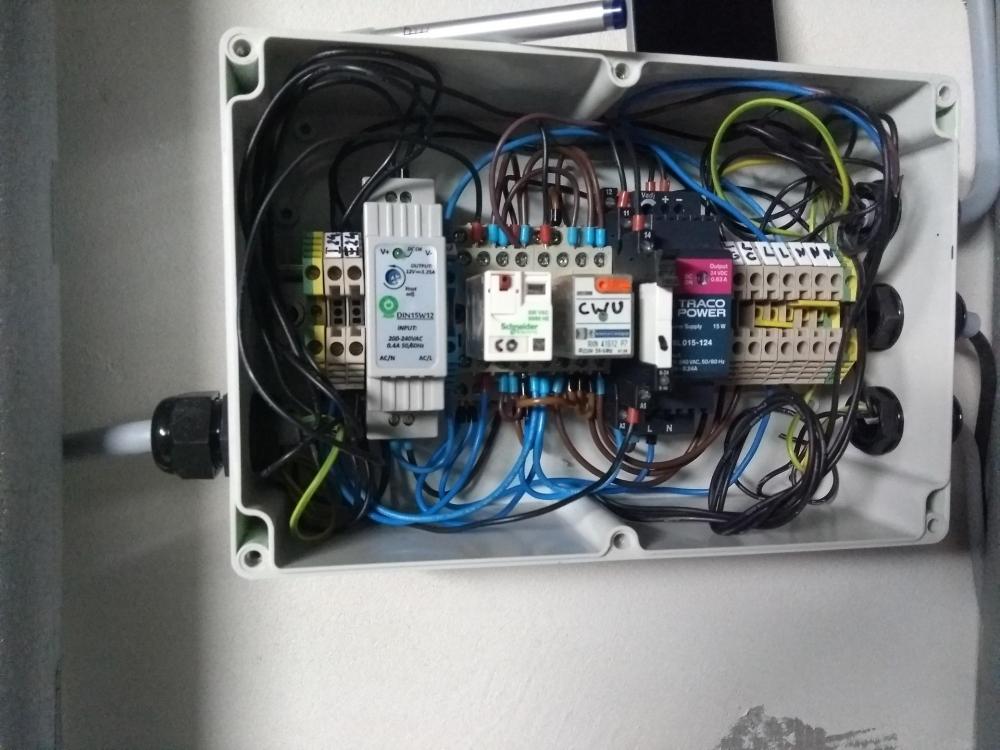

Now I will add few pics. Quick explanation to all - I am not based in UK or even in EU. I live in the middle of nowhere and Install is done with all possible materials I could possibly get on the market. It is done in resonable way and its safe for me for my domestic purpose. This is 1K£ project and I have sticked to the budget. There is one more connection box on the other side of the wall in my basement to which all this pictured is connected. I also heve there small knob and relays to switch between ASHP and oil boiler. At picutre no. 3 there you can see small hour counter sitting on the pipe. I have done some calculation - how many hours a day (including HW preparation) unit works and what is the daily power consumption. And this is something that absolutelly brings the smile on my face. - reading from the 2/11/2018 - 18,7kWh used, total run for 24h - 9,5h. 18.7/9.5 = 1.97kW 2kW to keep 22.5 degree of C at entire house! That is less than my kettle! Regards -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Hi, pictures above were added by other happy users of PUHZ-W90. Nothing to do with my install and my "customised" contoroller. -

IVT Ecolane ASHP - any owners out there?

testom replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Hello everyone, Quick update from me in terms of connecting PUHZ-W90. Like I wrote before I get this ASHP few weeks ago. That basic controller which normally comes with it was not included. Never mind. Thanks to PeterW everything was preety easy to do. 1- The unit it has been placed outside, and it is connected via 1` pipe work to small loop filled with 50% of glycol (5.5l)- flow pump, filter, expansion vessel (2L),air bleeder valve, ball valve, fill valve and plate heat exchanger. In this loop entire pipework is not exceeding 5m. 2- CH loop (filled with water) is connected to above mentioned heat exchanger from the outer side. 3- I did not wanted to spend extra money on any controller (already did) so I have made one like I wrote few days ago - based on set of 5 electronic termostats- each individually set, and I have added also to these few relays (7 of R4). 4- I have done for myself a possibility to have a controll on what power unit works - with a help of ZBE 101 and 102 switch elements. I set 3 steps (3- position knob) of power. In each step pump starts on different level. Step 1 - 77%, step 2 - 88%, step 3 - 100% of its power. Each step then has 3 smaller steps: 1- 77- 53- 42 2- 88-64- 53 3- 100-88-64 During run - as soon as temp at outlet is rising termostat 1 (set to 48C) gets active and power goes down to another lower step i.e. start at 77% - then 53%. After that I have another termostat set to 51C. If temp still rising termostat nr 2 triggers and output power goes down to 42%. When after that temp still rising there is another termostat set at 61C. This one when activated Stops the ASHP untill temp will get down to 51C (hysteresis). There is another run mode (HW- mode - start output power 42%)- with ist separate set of termostats- 1first set to trigger at 56C- and power goes down to 30% , and second termostat set to 60C- when trigger (hysteresis set to 1degree only)- is opens for a moment main loop of CH instalation and pumps hot water on radiators (it takes about 30-40sec and temp goes down to 56C). All above mentioned tested. Works very very well. Each termostat has hysteresis set accordingly. ASHP is running for last 7 days. Lowest temp outside I had in my country during this week was 2C. For all this week (except tests) pump was set to STEP 1 (77% of its power). Because I installed extra heat exchanger, water temp on radiators goes up to 43C (when pump is set to 48C). I had to do the install like this cos of the outdoor temp in my country goes well below -20C from time to time. So small glycol filled loop seems to be good option. Like I wrote before. This ASHP is just an extra source of heat in my building. And because I have some PV panels I can munch little bit of kWh. By the way- Pump consumed for last 7 days 175kWh(separate meter installed). Not bad I think. All together for CH and HW. Since ASHP is running oil boiler is off. I may be able to post some pics if anyone will be interested. Regards