PTUK

Members-

Posts

16 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

PTUK's Achievements

Member (3/5)

1

Reputation

-

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Thanks Dave Last year the pump ran at 1 all year no issues. This year because of the error U1 I tried different pump speeds currently running at 3 for the last couple of weeks. I definitely take enough heat out. Inconing temp @ 55'C returning temp @ 35'C I do believe it is overtemp in the HP but can't figure out what is causing it. Thanks Pieter -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Hi guys Update, today the error U1 is coming on frequently. I bridged the U1 connector on the board to keep the HP running while testing the 63H switch. I monitored H63 with the ohm meter and the 63H switch does go open circuit which will cause U1 error. If I turn the demand for heat off the H63 goes back to short circuit quickly within a minute. Now the real questions. Does it really build up too much pressure causing the H63 to activate and if so why? Or is the switch activating too soon? Thanks Pieter -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

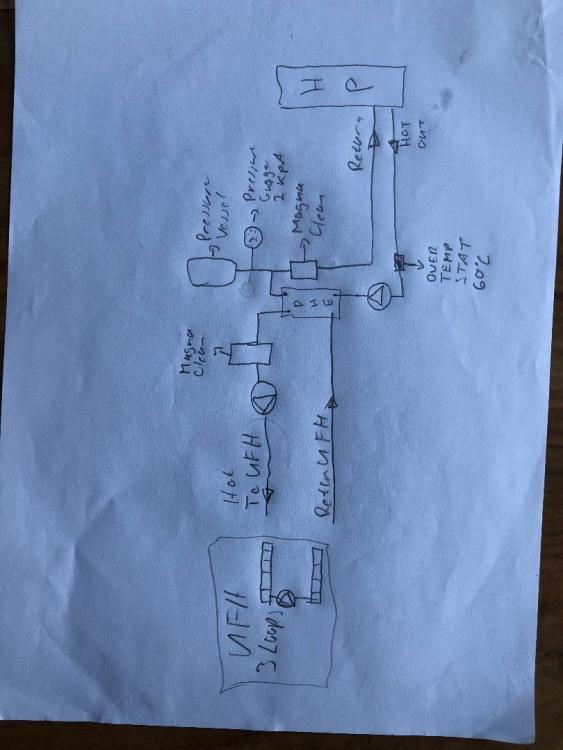

Hello Guys After a bit of help please. Error U1 Our DIY installed (with tanks to all the knowledge and help from this forum) IVT ran perfectly last winter. It warmed UFH up every night for 7 hours during economy 7 times without any issues (we had a mild winter in Lincolnshire). Switched it off in the spring and left it off until this November (was this my mistake?) This winter we've had several U1 Errors - High-pressure switch 63H activated. according to the Ecodan PUHZ-W85VHA2 manual it could be several things. I've check it during the day and it runs all day without issue, which should rule out items 1 - 10. It seems to only stop at night, maybe when its very cold? Stops very randomly. I checked the H63 switch it is closed in normal condition I can't activate it to check if it opens when pressure is above 4.15 MPa every time I have a day off I run it all day and it doesn't error. Below is the list of possible causes according to the manual with a comment. Any help very much appreciated. 1 Decreased water flow - circulating pump was set on 1 last year tried 2 and 3 this year, currently on 3 2 Clogged filter of water pipe - Unlikely it works when running during the day 3 Dirt of plate heat exchanger - Unlikely it works when running during the day 4 Locked water pump - Unlikely it works when running during the day 5 Malfunction of water pump - Unlikely it works when running during the day 6 Clogged or broken pipe - Unlikely it works when running during the day 7 Locked outdoor fan motor - I hear the fan running 8 Malfunction of outdoor fan motor - I hear the fan running 9 Short cycle of outdoor unit - Unlikely we run it 7 hours at a time 10 Dirt of outdoor heat exchanger - It is clean around and inside 11 Decreased airflow caused by defective inspection of outside temperature thermistor (It detects lower temperature than actual temperature.) - Clean but could be intermittently defective? 12 Disconnection or contact failure of connector (63H) on outdoor controller board - Checked the board, cable and plugs looks like new 13 Disconnection or contact failure of 63H connection - Checked cable and switch tested shows short when in normal condition could be intermittently defective? 14 Defective outdoor controller board - Looks like new could be intermittently defective? 15 Defective operation of linear expansion valve - I have no idea 16 Malfunction of fan driving circuit - Seems ok fan speeds up and slows down sounds normal Thanks Pieter -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Hello guys Some more questions unfortunately The screed is now dry so it’s time to connect the ASHP to the underfloor heating manifold. I’m struggling to find the braided flexible hose 1” to 28mm compression fitting can anyone point me in the right direction? Is 4 core cable ok between the grey 24volt box and the ASHP? What antifreeze / inhibitor should I use Thanks Pieter -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Yes sorry it is a thermal store that’s why I’m considering storing any excess heat in there but only if it doesn’t compromise on the efficiency of the ASHP and UFH -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

PeterW at the moment I think I’m just going with your earlier suggestions about reconfiguring the UFH manifold and run the three loops on the ASHP The DHW is a new tank fitted by me this summer it is 350 litre it has 3 pairs of “inputs or outputs” the whole tank is filled with “dirty fernox treated” water the DHW comes straight from the street through the heat exchanger and to the hot water taps. It has 2 x emersion heaters. Currently wood burning stove also supply heat to the tank 10 radiators connected to one of the outputs. the original plan was to only have this tank heated by the wood burning stove and emersion heater on economy 7 electric. Tank was going to supply heat to DHW and 10 radiators and the 45m2 UFH however it has become evident that I’m at the limit of what this tank can cope with so that’s why I got the ASHP to just run the 45m2 UFH The tank has a pair of inputs spare and if the ASHP has spare capacity and its feasible I am considering connecting the ASHP to the tank but I’m not hell bent on getting this done if it’s too much for the ASHP the idea of preheating the DHW through a separate buffer tank would have been very nice but the pipe work for this is just not feasible -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

With only 5 litres in your ASHP loop then I’m sure I’ll be ok with just my 3 x UFH loops total 45 litres with the ASHP and UFH running as a stand alone system using the suggestions from PeterW - this is currently my preferred option. However I do have a pair of spare inputs to my hot water cylinder and if possible I would like to dump some excess heat into DHW but not lower than 50-60 degree c What is this flap valve you are referring to does it only allow water through if it’s above a certain temperature? -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Hello and thanks for your reply. how big is your separate ASHP loop? You run a separate pump to a heat exchanger inside? if I do go with this then I could potentially have a three way valve from this heat exchanger split to the UFH and to DHW? -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

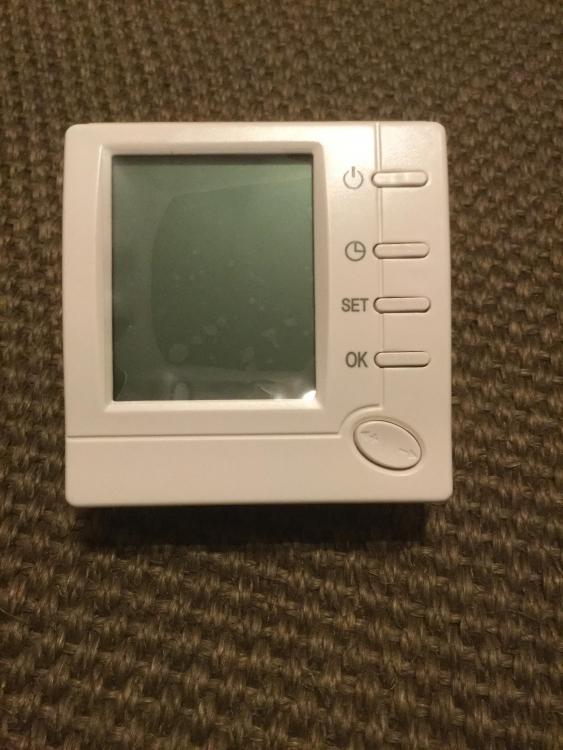

I don’t know if the switch is required it was just a thought I wanted to run by you guys. The only reason i’m using Grundfos pumps is I have a few spare. Few more questions now please guys. 1 On the Wunda self balancing actuator there are four cables two clip onto the flow and return and I assume one is neutral and the other go to pin 7 on the thermostat in the pic? 2 It is one big room with three loops to avoid joints in the floor I plan on using just one thermostat but can I run all three Wunda from pin 7 on one thermostat? 3 Do I use pin 3 & 4 to start and stop the ASHP and the pump at the same time? 4 The heating loop must be pressure tested before the screed is 5 bar ok? thanks for all your help guys very much appreciated. -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Ok thanks PeterW really appreciate all this help. I’m going to install everything as you suggested including the Wunda actuators and a ball, valve in the bridge link for the 4th loop. “The IVT box runs 100% or nothing, it bridges the A1-A2-A3 connections. You’re going to need to break that up as 100% will cook the floor.” - I understand this bit and how to set it for 45% but if it’s very cold like -8 does the IVT need to step up to the next power step? Did any of you guys ever experience such cold weather? Did any of you guys considered a multi way rotary switch to manually add or reduce the % power of the IVT in extreme cold? -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

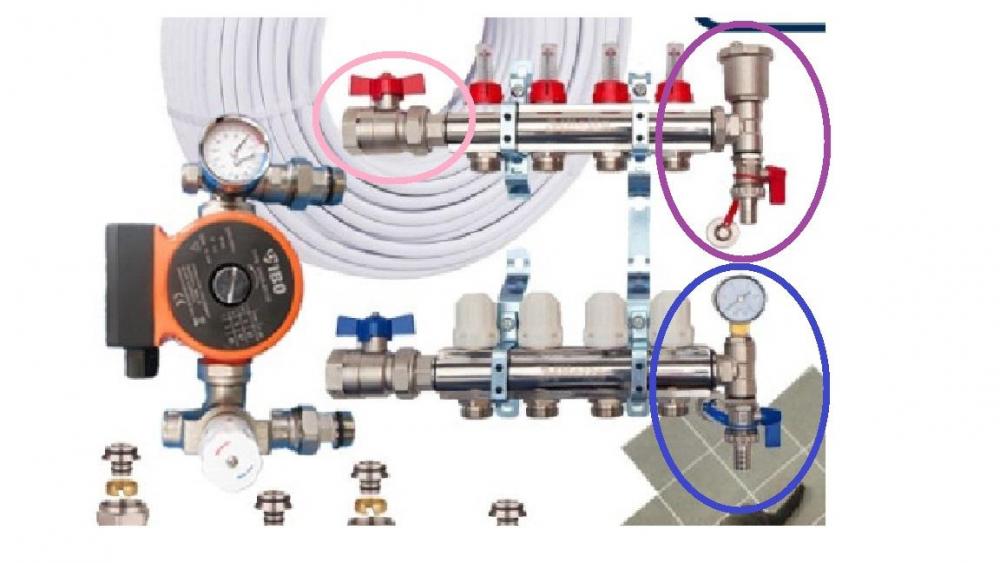

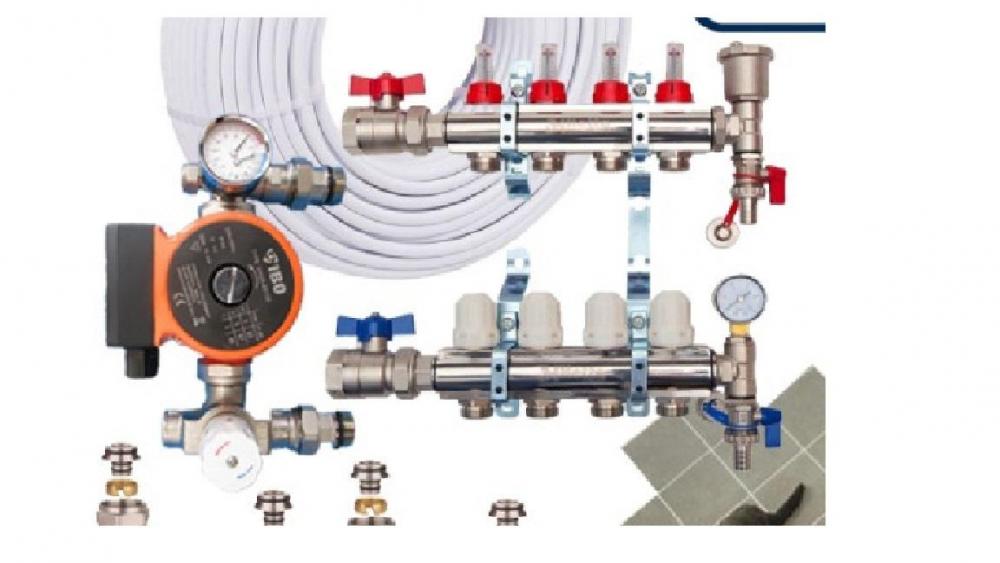

Ok some of this understand and some not. Total newby sorry. "I would bin off the blender" - yes easy, also easy to add the 8 litre expansion vessel here. "connect the flow from the ASHP through a butterfly valve direct to the manifold" - can I use the ball valve currently between the pump and the manifold (circled in pink)? "You’ll need a fill point too but you could be clever and use the drain valve on one end of the manifold as these don’t have one way valves on them." - can i leave the fill with the bleeder (circled purple) and the drain with the pressure gauge (circled blue) where they are and just add a small loop between flow and return on port 4? "return, run through a mag / particle filter and then use a length of copper pipe as the sensor section for the pipe stat which could be where your pump goes." - yes easy, also add antifreeze here. "I’d consider using the Wunda self setting heads to regulate the flow - not expensive either. It will regulate the flow to 7c but you will need the bypass as it could shut the lot down and the ASHP may go into overheat mode." - I am concerned about shutting flow down with actuators / heads do you think it will be ok without? "run the ASHP on setting 4 which means from memory that the positive from the 24v goes to A5, and the negative goes to A2. Should give you 45/50%" - So I just use the grey box for the 24 volt power supply inside it? there doesn't seem to be much more than that in there anyway. "Where are you in the UK out of interest ..??" - I'm in rural Lincolnshire near Boston no gas or oil. -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

That's good info thanks. I do have a few red grundfos heating pumps so I shall use one of them instead if that orange one. Unless you think I should just get a new willow. -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

It is the UHF kit from eBay. Manifold is on the wall and the first loop is on the floor, other two loops will go down this weekend. The extension is one big room kitchen, diner, sitting area 11 x 4 meter just one thermostat because it is totally open. 3 UHF zones because the pipe is only 200m per roll and I didn't want joints in the floor. Could you give some more info on the rework please, I do have a few red grundfos heating pumps so I don't mind adding a pump between the ASHP and manifold but if it's not required or better without then that's ok. I was considering not using the actuators to prevent the loops from closing, just stop the ASHP and pumps when the thermostat stops calling for heat. -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Ok i did think no antifreeze is a big no. I did like PeterW's suggestion and so far it's what I shall try first. -

IVT Ecolane ASHP - any owners out there?

PTUK replied to readiescards's topic in Air Source Heat Pumps (ASHP)

Thanks for the reply everyone, I have the IVT Ecolane 9KW I shall fit a magnetic filter in the return pipe. I have a pair of spare inputs to the gledhill cylinder,. Could I use a three port valve to split the output from the ASHP to cylinder and UFH? I'm not sure if i can add antifreeze to the gledhill and even if i could it has a 350 litre capacity so would need lots of antifreeze. The ASHP is just outside the new extension wall and the UFH manifold is just inside the same wall so only 400mm of flexi pipe is outside will it be ok without antifreeze? Gav_P I was worried about the minimum water volume in my system, your DHW probably add volume to prevent short cycling. Jack This minimum water volume is what is worrying me 9KW ASHP and only about 45 litres of water in the UFH JSHarris I have a 4 port manifold with 3 loops used (the 4th loop is just a short pipe from flow to return or a big radiator in the garage next door to add load and capacity if required) total about 450m pipe so 45 litres in the pipes so I'm far short of the minimum capacity. When your buffer tank warms up what happens to that heat? PeterW Brick and block walls with cavity slab filled 100mm cavity, 100mm floor insulation with 70mm creed with heating pipes inside. I worked on 1KW per m2 of floor so i expect to need about 4.5KW. I add a pic of the manifold it is the blending type. You have lots of pipe run I only have 2 meter pipe between ASHP and UFH manifold so if the blending valve restricts flow then there will be very little water in the circuit.

.thumb.jpg.66955121f0373309f6b271070234faf9.jpg)